Water flows from the pumping station. Why the pump does not pump water

Debugged water supply system in the country or in country house may one day fail. An analysis of indirect causes helps to identify inoperability, because it happens that the pump works, but does not pump water or dispenses liquid unevenly, as if in jerks.

Minor damage can be fixed quickly and independently, but for serious work it is worth contacting professionals. Most often, you will need to pull the device out of the well or well in order to visually assess the current status of the pump.

Diagnostics

We identify the reasons why the pump does not pump water from the well. They can have a mechanical nature due to physical damage to the housing, individual parts or assemblies, as well as when the passage channels are clogged.

On the eve of the water could come from the pump in a muddy form, but the pressure was maintained without lowering the output force.

- In such a situation, the cause may lie in the well itself. It is clogged or siltation has occurred. The blame for these events are some types of algae.

- Sometimes various impurities penetrate into the liquid, which are lathered by the flow. In this case, slight shedding from the sandstone walls can be carried out, which causes sanding.

Flushing

A certain volume of the well will always be occupied by certain impurities. Substances block the flow of fluid into the drilled cavity. Initially, it will penetrate with the sand, and later - mixed with air. This behavior indicates a significant contamination of the tidal fontanelles. Simultaneously with this factor, protection against dry running does not work, and the consequence is that vibrating pump buzzing but not pumping water.

The main treatment consists of the following operations:

- primary pumping of water from the cavity is carried out;

- disinfection of the space;

- re-pumping water.

The last point is performed after a certain period of time. The interval depends on the power of the disinfector used. Elimination of the causes should give a positive effect and ensure the operability of the system.

Alternative recovery methods

Let's see why the pump does not pump water from the well, even after flushing it. Such situations do occur, albeit rarely. Influencing factors may include the following options:

- mechanical breakdown;

- partial failure of the electrical system;

- depressurization of hoses, which were flooded by prolonged exposure to water;

- breakdown of control system elements.

An accurate analysis will be possible when displayed on the surface of the pump. Having taken out a vibration, screw or screw pump for a well, the apparatus is placed in a container with water. After that, the electrical part is started. In the standard mode of operation of electricity, it is not necessary to independently penetrate into this part, since an unprofessional person may inadvertently damage some nodes there.

In the event that the start on the surface did not take place, then a multimeter and an electrical circuit are needed. It indicates the tested parameters and the necessary normal operating values. If defective parts are identified, they can be replaced independently by soldering / soldering a burnt capacitor or diode, etc.

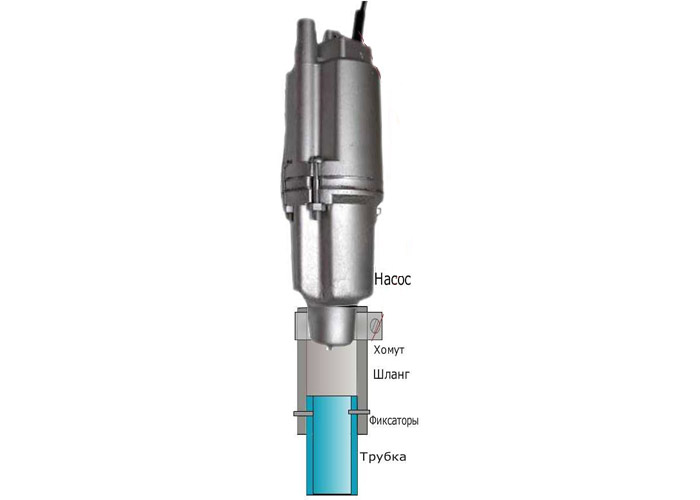

When the electrical part functions correctly and the pump works, but does not pump water, you need to turn on the unit and conduct visual inspection of the pump casing and the integrity of the hose. Gusts in the plane or abrasion contribute to depressurization.

Visual inspection of the hose is not always able to identify problem areas, so they use artificial injection of air into the cavity, closing the hose on one side. Where air comes out, a characteristic sound will appear.

Repairing the patch or patching it will be ineffective, so a partial or full replacement of the flexible main hose will be required.

VIDEO: Troubleshooting a Pump Station

The influence of internal factors

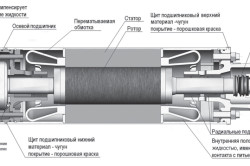

Not always submersible pump for water it pumps weakly or stops pumping due to problems with the electrical part or hose breaks. The reasons often lie in the internal structure of the device. As preventive operations, the following actions are carried out:

- visual inspection of filters that may clog;

- a valve is also tested, which is also capable of failing for the same reason.

All filters in the flail are cleaned of possible clogging. In most cases, this helps to reanimate a practically working device. It is important to check for dry running. If the control sensor for this function is unstable, it must be replaced.

Excess Power Source

The device will be able to deal with power with the help of a passport of electrical goods. It contains the value in a specific format:

- cubic meters per hour m 3 / h;

- liters per minute l / min.

It happens in dry weather, the pump can pump out a column of water, while the owners do not have time to stop it in time. The effect of dry running.

This can happen with the simultaneous start of several consumers or a small debit from the supply springs. Be sure to select the performance of hydraulic equipment so that it is brought into line with the parameters of the well. The power reserve can not be large. For a large number of simultaneous consumers, a water use schedule is being built.

Voltage drops

Weak voltage in the household electrical network leads to poor-quality pumps. When lowering to 200 V and further, all devices operate with significant overloads, and the electric pump is no exception. Some models have a built-in internal stabilizer, which allows you to keep the constant voltage at 220V.

If such an element is absent in the structure, then it is allowed to mount a stationary stabilizer in the network. It can balance the voltage. Bringing it to 220V even from an interval of 160-260V.

What to do if a pump falls into a well

Such situations, when the pump fell into the well, although rarely, are encountered, so you need to know at least in theory what can be done.

1. Work equipment

If the pump is working, you need to use a variety of devices to lift it. It can be “cats” with bent hooks, which you can grab the unit for the protruding parts. There are similar hooks in drilling companies, which often provide services for the recovery of failed pumps from wells or wells.

Some recommend using neodymium magnets, known for their tremendous gravity. Such magnets are needed in cases where the well’s diameter is not much larger than the diameter of the pump and the “cat” simply won’t grab it.

2. Inoperative pump

If the unit is obviously defective, you can not touch it at all, but this is only if there is a large sump in the well and the pump that has fallen falls below the filter. In order to verify this, you will need ropes and weights to explore the bottom of the well.

When the apparatus interferes with water intake, it can be tried to break it down with a drilling rig, but it is expensive and not always effective.

If a pipe fell into the well along with the pump, you need to use a tap and a bell for catching.

The inability to remove a fallen pump can lead to the fact that you have to dig a new well, so use all known methods. The services of professional fishing apparatus will cost an average of 6-8 thousand rubles, which is not comparable with the cost of a new pump and, especially, a new well.

VIDEO: Lifting a torn pump

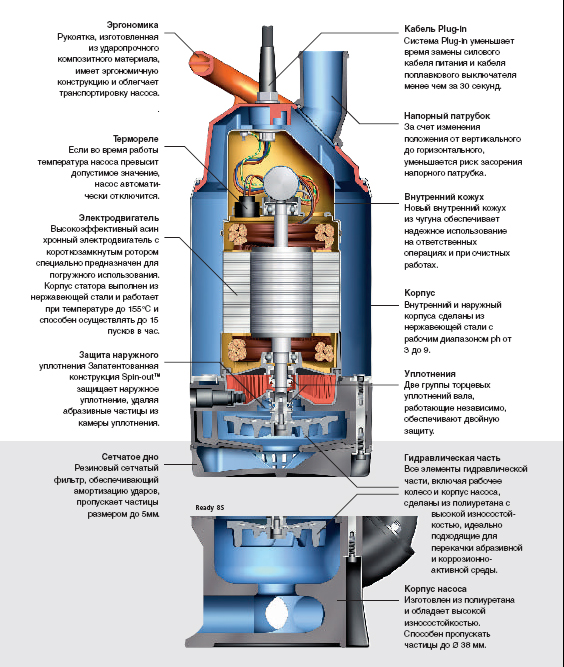

Submersible injection pumps have excellent technical characteristics. But often even the most reliable units are prone to breakage. About why pumps do not pump water, and will be discussed in this article.

Faults and reasons for their elimination

The main malfunctions of domestic pumps are:

- cavitation;

- insufficient power;

- excess current;

- the presence of deposits;

- water hammer;

- noise amplification at work.

Cavitation is such a process when a pump pumps water with air. There are several reasons that lead to this:

- clogged ventilation and supply pipes;

- the presence of gas or air particles in the water;

- a long pipeline for suctioning fluid is installed;

- pump operation with increased load on the right side.

Clogged pipes are cleaned. The hydraulics of the device are carefully inspected. If clogged, it is cleaned. Whenever possible, pipes are exchanged for products with a large diameter.

- deep immersion of the unit in water;

- fastenings of jacking shields (will prevent hit of a water stream on a site near the pump).

To reduce the loads on one side of the device, an increase in resistance on the pressure pipe is carried out. To do this, install additional bends or install pipes with a smaller diameter.

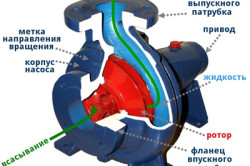

Insufficient power when the pump does not pump water well can be caused by:

- improper pump rotation (typical for 3-phase products);

- damage or clogging of the impeller;

- blockage of the flow line or jamming of the check valve;

- the presence of air particles in the pumped water;

- inaccurate valve position on pressure pipe.

The direction of rotation of the device changes by correctly connecting the two phases on the power cable. Corrosion and abrasion are usually a source of impeller failure. It can only be repaired by replacing damaged parts. When the pump mechanisms are clogged and jammed, they are thoroughly cleaned. The valve located on the pressure pipe must be fully open.

The main causes of excess current in the pump are:

- voltage drop in the electric network;

- increased viscosity of the pumping fluid;

- increase in engine temperature;

- shutdown of one of the phases.

Correcting these malfunctions is carried out using:

- constantly checking the voltage indicator:

- installing an impeller having a smaller diameter;

- restrictions on the number of stops and starts;

- thorough inspection of the contacts for connecting the cable;

- replacing failed fuses.

Blockage of the pressure pipe and pump deposits occurs when:

- the device is constantly turned on when pumping a small amount of water;

- the speed of the fluid is reduced.

You can fix this problem by setting new parameters on the control device or by changing the height of the water level when starting the pump.

The occurrence of water hammer is associated with:

- the appearance of air jams in the pipes;

- frequent start of the pump;

- pumping a large volume of water at the time of inclusion;

- quick exit of the unit to operating mode.

You can avoid or reduce the occurrence of water hammer by:

- installing the ventilation valve at the top of the pipe;

- checking the diameter of the pipeline and the operating point of the pump for their compliance with the speed of water movement;

- use of soft start frequency;

- optimal settings for operation on the control device.

An increase in noise during the operation of the pump does not directly affect the amount of pumped water. But this fact indicates that after some time other malfunctions will appear. And they can lead to the fact that the pump will not be able to pump water. After all, the causes of increased noise are completely different, ranging from clogging of the ventilation pipe or flow line and ending with the effect of corrosion on the impeller.

Problems encountered when operating two types of pumps

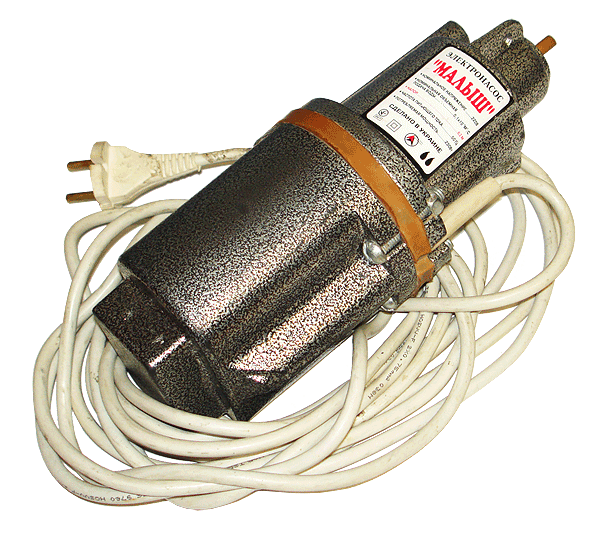

Among deep pumpsintended for use in everyday life, the most popular units are "Kid" and "Agidel".

The main reasons that the pump "Baby" does not pump water can be:

- shock absorber displacement;

- rubber valve wear;

- breakage of the rod.

The shock absorber displacement is explained by the weakening of the fastening of two nuts. They are placed on top of the shock absorber on the stock. A return to normal pump operation is achieved by disassembling it and tightening the nuts all the way.

The rubber valve wears out when sand enters the pump with water. Valve replacement also takes place during disassembly of the unit. Sometimes the reason for the lack of water can be getting under the valve one small pebble. As a result, the valve cannot close. After removing the pebble and adjusting the valve, the pump will operate in normal mode.

If damage or deformation of the stem occurred, you will have to resort to the purchase of new equipment.

One of possible malfunctionswhen the Agidel pump does not pump water, wear of the stuffing box is. In this case, replace it. This process is carried out in the following sequence:

- the cover is removed;

- the motor housing is unscrewed;

- the rubber gasket is removed;

- unscrews the nut that secures the impeller to the housing;

- the anchor and bearing are removed from the shaft;

- the old is removed and a new oil seal is put.

Nuances of disassembly and operation of the pump

Some requirements must also be observed when disassembling deep pumps. These include:

- the gap between the magnetic system and the piston is 4-5 mm;

- valve and piston integrity;

- the gap between the valve (located near the suction holes) and the body is 0.7-0.8 mm.

It should be noted that the operation of the pump without water, even for a short time, can cause it to burn. As a result of equipment overheating, the magnet peels off and the gap between it and the piston disappears. After this, the movement of the piston becomes impossible.

Pump repair video:

- Diagnose the cause of the breakdown

- What to do if well cleaning didn’t help

- If the electrics and hoses are working

- Additional recommendations on the topic

There may be several reasons why the pump does not pump water from the well. Our publication will help you understand them and fix the breakdown. You will not surprise anyone with a well in the country or near the house. This is convenient, hence the popularity of wells. But the idyll lasts as long as the water continues to flow into the consumer's house without failures. It happens that problems happen and you are horrified to notice that the pump has stopped pumping water.

Diagnose the cause of the breakdown

There may be several reasons. And they can be associated with both mechanical damage to certain pump components and clogging of the well itself. First you need to remember what water came from the well on the eve of the problem.

If the water was cloudy or its pressure during the normal operation of the pump began to decrease sharply, then the problem lies most likely in the well itself. It clogged or silted. The aquatic environment is a great place for the development of certain types of plants. In addition, impurities washed by the flow can enter the water, and material is shed from the walls of the well. The so-called sanding of the well takes place.

All these factors cannot pass without a trace: a certain amount of the internal space of the well is occupied by impurities that impede the access of water. First, it enters the system with sand and silt, then with air. This means that the well is very clogged, and the system of protection from the "dry" mode of operation did not work. There is only one way out: the water from the well must be completely pumped out, the internal space must be disinfected and the water pumped out again.

Re-pumping is carried out after a certain time, which depends on the disinfectant used. After carrying out cleaning procedures, the pump should start operating normally. But even if this did not happen, do not despair: all the operations done will benefit both the well and the pump itself. Indeed, even in the old days, people periodically cleaned their well in order to improve the quality of water in it. In modern conditions with polluted ecology, the well cleaning procedure can and should be carried out more often.

Back to the table of contents

What to do if well cleaning didn’t help

Consider the case when, after cleaning the well, water does not come from it. Here the reasons can be of several types:

- mechanical breakdown of the product (pump);

- damage to the electrical system;

- violation of the integrity of the hose system;

- failure of one or more elements of the control system.

To determine the defect more accurately, the pump must be removed to the surface, placed in a container of water and turned on. If, when turned on, the pump motor is operating normally, then there is no damage to the electrical system. And this is good, because problems in the operation of electrical elements are difficult to diagnose to an inexperienced specialist. After all, the tester will have to check all the elements, checking their readings with the technical documentation for the product. Such work will require certain skills and will take a lot of time. If a malfunction is detected in the electrical circuit, it will need to be repaired or the defective element should be replaced with a working one. This can be a power cable, relays, fuses (it is necessary to start the analysis of serviceability with them).

If there is no problem with the electrical component, then just observe the pump operating mode and try to visually check the integrity of all hoses. Violation of their tightness leads to a drop in pressure created by the pump, and water does not rise from the depths. On the surface, checking the integrity of the hoses is not as easy as it might seem at first glance. Purely visual leakage may not be noticed. Try to tightly cover the mouth of the outlet hose with your palm, creating an obstacle to the movement of water. The pressure inside the hose will increase and water jets will certainly be visible at the site of damage. Closing the hose is much harder than replacing it with a similar new one. The fact is that when lifting liquid from a great depth (more than 5 m), the pressure inside the outlet hose will be large, which will lead to the elimination of the patch or even greater damage.

Back to the table of contents

If the electrics and hoses are working

Now suppose that the hose system is not damaged and is working properly. But if the question of why the pump does not pump water from the well is still relevant for you, then this can only mean one thing: the reason must be sought in the pump itself.

First check the filter and valve for clogging. The problem in most cases is located in these places. It is enough to thoroughly clean the named elements or replace them with new ones, as the problem itself will be eliminated. The second node that needs to be checked is protection against the "dry" mode of operation.

The sensor could easily burn out, which caused the electric motor to work in an anhydrous environment. This mode of operation can lead to rapid overheating of the engine and its complete failure. It is better to replace the water level sensor and protection against the "dry" operating mode, repair is extremely undesirable here.