Buy boosting pumps for cold water supply. Boost pumps and pumping stations are used. Booster pump installation

Booster pumps for water are an integral part of water supply systems. Such installations are necessary for buildings with no centralized water supply, or when the level of water pressure in the water supply is insufficient for the normal operation of household appliances.

Booster pumps are often used for individual or central heating systems. Increased pressure of hot water improves the quality of heating systems.

Strong and durable brass and stainless steel construction. This manual mainly refers to electric solar water pumps, which are used in typical solar electric systems. Information is also provided on the use of AC electrically adjustable pumps in systems with an inverter. Electric pump solar water pumps are used for pumping at large or shallow depths for tanks, irrigation, water pressure systems and many other areas.

This manual is recommended for lecturers for installers, users, and probes, especially those new to solar electric pumping systems. Capacities and limitations Solar water pumps come in many types. One of the most common is the low pressure boost commonly used in tank water supplies. Others include a diaphragm and a piston with dumbbells, pressure boosting pumps, circulation pumps, groundwater sampling pumps, etc.

1 Device and scope

Booster pump for water supply - a robust monoblock design, the main elements of which are a pump and an engine. For the manufacture of parts of the flowing part and the working case, constantly in contact with water, durable anti-corrosion materials are used - cast iron, brass or stainless steel.

Advantages These low-power pumps allow us to build a solar pumping system for a deep fountain at a modest price. They are cheaper than windmills and, if necessary, consume water in a clean and sunny environment. They can be installed and processed manually. Works in very low-yield wells that conventional pumps can pump in minutes. Pumps can pump 2 liters per minute.

Pump Controllers Many of these solar pumps require a special controller if they must be powered directly from the PV modules. The controller or auxiliary container with linear current acts as an automatic transmission that allows the pump to start and operate in low light conditions such as cloudy or early morning and evening mornings. When powered, a controller is not absolutely necessary, or a special controller can convert a 12-volt battery to 30 volts for a full pump.

The housing of the working part is open on one side only. A front suction bell is located above the pump shaft. The feed bell is placed over the shaft.

Models with a hydraulic accumulator or a membrane tank are more productive for water supply with a constant lack of the necessary pressure. The membrane tank accumulates a supply of water, depending on the volume. When cranes or household appliances, such as boilers, washing machines, and dishwashers, are turned on, this supply is used first.

Thus, the local highway is provided with the necessary starting amount of water. As it is used, the pump fills the tank.

Boost pumps and pumping stations are used:

- for raising pressure and transporting water in a house or industrial building;

- in main pipelines, at waterworks;

- to increase the pressure in the production plant;

- for transporting fluid to a fire or cooling system.

1.1 Types of booster pumps

Depending on the control method, pumps to increase water pressure are:

- automatic

- tame.

Pump operation with manual control controlled by the operator. Turning on and off is forced.

Aggregates with automatic control equipped with water flow sensors. They work when the crane is opened and ensure the installation is turned on. After closing the tap and stopping the flow, the sensor turns off the pump.

Depending on the technical characteristics and working conditions, these types of pumps are distinguished:

- surface centrifugal;

- jet centrifugal;

- vortex.

Principle of operation surface centrifugal pumps such: a working impeller is installed on the driving rotating shaft, in front of it there is a suction pipe, which is located at the bottom of the pump housing. The impeller's task is to create a radial movement of water from the center to the periphery. Hydraulic losses are minimal.

Inside the impeller there are radial blades, which, when the water moves, convert mechanical energy to pressure and flow acceleration. After exiting the impeller, water is directed into a spiral, with the help of which it enters the conical diffuser. There kinetic energy is converted into energy of pressure.

Centrifugal Jet Pumps - A type of centrifugal pump. An ejector is installed inside the casing, which provides a self-priming effect. Part of the fluid pumped by the pump enters the discharge pipe. The part that remains is recycled with an ejector that attaches to the suction chamber. Recirculation creates a vacuum inside the suction chamber, which contributes to the self-absorption of water.

There are such types of pumps in which the suction chamber with the ejector is carried out in a separate unit and connected to the pump by two pipes. The block can be lowered into the well.

Vortex pumps have radial blades on the periphery of the impeller. They transfer mechanical energy to the pumped water. Thanks to the device of the blades, they provide a radial recirculation of water that enters the pump. Blades and double channels are located on both sides of the impeller. Between them, water is recycled.

Numerous blades promote energy transfer, this leads to a gradual increase in water pressure. As a result of this work, the flow at the outlet is uniform, with high pressure.

1.2 Features and Benefits

To reduce the noise level, most household boosters have a rotating rotor located directly in the pumped liquid. Such designs are called wet rotor models.

All elevators are small in size, so they are easily placed on the pipe. Easy to operate in private homes and apartments.

Despite the fact that the pumps slightly increase the pressure in heating and water supply systems, even such a minimal increase in pressure improves the circulation of the coolant in the batteries and ensures the normal operation of boilers, washing machines and dishwashers.

The liquid with which the enhancers work can have a temperature in the range of 10-100 degrees. The air temperature should be below 40 degrees.

Pumps for increasing water pressure have several advantages:

1.3 Efficiency

The reason for the weak water pressure is not only clogging of the filters and overgrowing of pipes. Often a weak head is the result of a large intake of water at a certain time. If apartment buildings quite easily cope with a similar problem, then for private construction autonomous water supply systems are simply irreplaceable.

The device of the pumping unit, in the complex of which the drive is included, eliminates the problems of general water intake. Systems using surface and submersible pumps have many advantages.

During the installation of such equipment on the highway, often with excellent performance indicators there is no work efficiency.

This happens because when the booster is installed, the water pressure does not increase, since water is drawn from different points. As a result, the amount of water that enters the pump will constantly decrease. Especially if the neighbors below also installed a pump to raise water. As a result of lack of water, the pump starts to work as much as possible. This leads to premature wear of parts and reduce the life of the product.

To achieve work efficiency and increase pressure, it is recommended to install storage tanks in parallel.

2 How to choose the right pump to increase the water pressure?

When buying equipment to select the optimal model, you need to pay attention to its capabilities.

The main selection criteria:

- operating temperature;

- power;

- noise during operation;

- way to connect to the water supply;

- pressure;

- bandwidth.

In order to maximize the operating time of the unit, it is necessary to avoid its operation at maximum permissible temperatures.

If you need to slightly increase the pressure of water at a short distance, you do not need to buy a very powerful mechanism. A high power engine consumes more electricity. It is more profitable to purchase a less powerful model that can easily cope with such a task.

The way to connect to the water supply plays an important role, because basically the supercharger is connected covertly so as not to spoil the interior.

For a small room, a noise level indicator is very important. When installing equipment in a basement or other enclosed area, noise during operation does not play a special role.

One of the most important selection criteria is maximum head. Power is not always an indicator of high pressure. There are models with low energy consumption that can create high pressure.

A direct indicator of the filling speed of the required capacity is the throughput. Measured in cubic meters per hour.

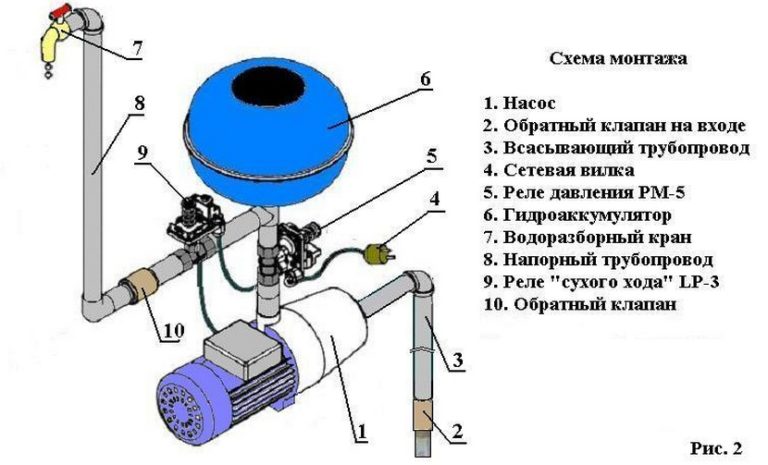

3 Installing booster pump

For the effective operation of the unit, you need to connect it correctly. When installed on a common line in a pipeline, the pressure will increase on all branches of the pipeline at home. Since the area of \u200b\u200bthe pipes is large, the pressure created by the supercharger in the separated sections of the pipeline will be less.

As a result of this, the pump runs at full power, and the efficiency of such work remains negligible. Especially if water is taken from several points at once. Installing a unit with more power will not be profitable in terms of power consumption and noise during operation.

A suitable and low-cost installation option is to install on the pipeline in front of the consumer. For whom the constant support of the necessary pressure is important. With this installation, the pressure on the other lines will not change.

Sometimes it’s better to install several units at once with a small capacity on the necessary sections of the pipeline than installing one powerful unit on the entire pipeline.

In each individual case, the length of the pipes, their cross-section, and the pressure level are measured. This allows you to determine the maximum parameters.

Installation of equipment is not difficult:

- First make sure that there is a power outlet at the location chosen for installation.

- Further on the places of the cut marking is done.

- The water supply is shut off and its residues are drained from the pipeline.

- The pipe is cut and an external thread is installed.

- Adapters are screwed.

- Fittings are screwed.

- Using a three-core cable, the unit is connected to the shield. In this case, an individual machine is installed.

- The joints are checked for leaks.

After that, a test test is carried out. The first start of the pump is carried out only after the water circulation resumes. If the verification is done by specialists, an act of verification of booster pumps is drawn up.

Thus, this equipment can eliminate low water pressure. But for its maximum efficiency, you should choose the right model and take into account all its characteristics during installation. To control the technical condition of the unit, it is also very important to install in an easily accessible place.

3.1 INSTALLATION IN THE APARTMENT OF THE SURFACE PUMP GPD 15-9A (VIDEO)

The problem of lack of pressure in an autonomous water supply system is not uncommon. Often this comes from incorrectly selected equipment with a mandatory storage tank at the top point - in this case, water flows by gravity. The system is suitable for a summer residence, however, to meet the needs of a residential building - it is absolutely not rational. Pressure is not enough even for hygiene needs, not to mention the amount of equipment requiring water. In this case, experts recommended a booster pump for the water supply, which increases the pressure in the system.

Types of booster pumps - which one to choose

The device is an assembly designed for tapping into a system to increase existing pressure. The range of the parameter is from 1 to 3 atm. The classification of these products is as follows:

- Type of cooling. Dry and wet rotor. The first unit is characterized by high performance, however, noisy. The second for numerous needs is ineffective, quite acceptable in summer gardening - watering, outdoor shower, bathhouse.

- The method of inclusion. Automation and manual mode. Naturally, the first option is preferable. It is equipped with a flow sensor that monitors the operation of the device. In manual mode, you will have to monitor the heating of the pump. There are also combined models that allow, first of all, to save electricity during short-term starts.

- Installation Horizontal, vertical, in any plane. The one whose position is suitable for the water supply section is selected.

- Speed. Multistage models allow you to smoothly increase the pressure in the network.

- Type of construction. Compact In-lines work on any part of the water supply, but at the same time they are low-power, which will affect productivity. Vortex models are noisy, require special piping, but at the same time provide the proper level of comfortable use of the water supply.

- The material of manufacture. Traditional cast iron and stainless steel. The first is fragile, sensitive to water hammer and temperature changes, if the pump will be used for hot water. The second is not cheap. Impeller material also matters - plastic is suitable for seasonal summer cottage needs, bronze and brass - for residential.

Based on the classification, a choice is made. As a rule, for cottages they acquire compact built-in units with low productivity and one speed. For a residential building requires something significant.

Specifications

Almost always, the specifications given in the instruction manual indicate the maximum value. To determine the real parameters, the values \u200b\u200bare divided into one and a half, two times. Then they make a choice in favor of a particular unit.

In detail:

- Maximum working pressure. Actually, for what the unit is bought. For giving 2 bar is enough. A residential building often requires more than 3 bars, but since the pumping equipment of a residential building is more powerful than a country house, this value is enough.

- Maximum feed. The bigger, the better. Measured in l / min or cube. m / hour. For watering or a summer shower, an acceptable figure of 1.8 cubic meters. m / hour. For the needs of the house, the parameter is carefully calculated.

- Maximum head. Regarding the well, the main work will be done by the downhole equipment, but it remains to bring the resource to the house, and they are often in two floors. Therefore, take into account the total height from the basement.

- Circuit. Pumping equipment requires an uninterrupted source of electricity. If the home network is replete with frequent interruptions, it makes sense to think about purchasing additional equipment that stabilizes the work.

- Flow rate. The parameter indicates the operation of the equipment after the pressure drops to the indicated value. Smaller values \u200b\u200bwill indicate a better model - the pump will begin to make up for the loss with minimal drawdown.

- Maximum and rated power. The value of the parameter is understandable - the higher the indicators, the better the pressure will be provided by the booster pump.

- Water temperature. The range from 2 to 100 C characterizes the model as universal, suitable for a residential building. Cold water supply is often required in seasonal dachas - an outdoor shower is provided by an electric water heater or collector.

- Inlet and outlet diameters. It is important to know in advance the connection area of \u200b\u200bthe unit, then choosing identical values \u200b\u200bwill be easier. Otherwise, flanges are used during installation.

The booster pump, which is most suitable for its object and source of water with its technical characteristics, is considered reliable. For the choice, the model and the manufacturer matter. Let's see what they offer:

Top 5 boosting pumps for home and garden

The Russian market is able to provide consumers with a wide selection of pumping equipment. Among the models there are budget and designed for high requirements. The following have gained popularity:

Booster pump Termica TL PI (Aquatic)

The cost is 3,700 rubles, which is easy for owners of a summer residence. The model is powered by a 220V home network. The maximum pressure of 10 m, the temperature of the medium can increase to 60 C. Consumption of 1.5 cubic meters. m / h allows you to provide all cottage needs.

Jemix Booster Pump

In addition to giving it is used for an apartment network. This is especially important for owners whose meters are located above the fourth floor. Standard food, but an uninterrupted power is required - if we are talking about an apartment. maximum temperature - 110 C, pressure 18 m. Price - 5600 rubles.

Grundfos Booster Pump

Leaders in pumping equipment. The price of 13 thousand rubles is most likely due to the brand, since some characteristics are inferior to inexpensive analogues - a pressure of 9 m, a flow rate of 1.8 cubic meters. m / hour. The model uses cast iron and stainless steel, which makes the pump durable. A substantial warranty is 2 years.

Booster Pump E.SYBOX

Italian manufacturer of pumping equipment for private residential buildings, cottages, production. Naturally, the characteristics are high: productivity - up to 5 cubic meters. m / h, head - 50 m. Lower carrier temperature - 40 C. The average cost is from 35 thousand rubles.

The pump for own needs is carefully selected. Overpay for functions that turn out to be unclaimed in the country - it makes no sense. For a house or apartment, on the contrary, a more powerful unit is required, otherwise what is the point in a working pump if it is not able to squeeze the required amount of water "uphill"?

Where to install the booster pump in the water supply system

To begin with, the installation scheme is thought out depending on the number of equipment and points of drawdown. As a rule, the pump is installed in front of household appliances or a boiler. For trouble-free use of water in the bathrooms, the installation location will be behind the storage tank. The pump does not do without a bypass - a bypass line. The unit serves to increase the existing pressure, and does not replace a completely circulating pump.

Connection is easy:

- At the insertion point, a water pipe is dismantled.

- The booster pump is installed using flange or coupling connections, of course, using a seal - rubber rings, tape-fum and other things.

- A bypass with a ball valve is welded on the same line.