How to install a pressure controller on a submersible pump. Water pressure switch for pump

Autonomous (decentralized) water supply systems are equipped according to certain schemes that require accurate calculation of all parameters. But just laying pipes, installing in a source device for pumping liquid is not enough to ensure the efficiency and reliability of engineering communications. You cannot do without automation that controls the operation of the pump. In the simplest version, it is represented by a pressure switch, which periodically (if necessary) turns it on / off.

In pipe systems where the installation of such a tank is impossible (undesirable), or with a complex communication scheme where high-quality control of several parameters is required, more advanced control automation is used pumping equipment (block type) with the inclusion of various sensors. Information on the devices of this group - at this link.

Pressure Relays - Model Overview

The principle of operation of all products in this category is identical. The algorithm is the simplest: the pressure in the system has dropped below critical - the relay turns the pump on; increased to the maximum set value (during setup) - it breaks the power supply circuit with contacts.

1. Unipump

Good domestic development, characterized by high quality and reasonable cost. It is delivered to the market in various modifications.

Features

- Designed to work with pumps up to 1.5 kW.

- Pressure gauge integrated in the pressure switch housing. Therefore, it is not necessary to install the measuring device separately.

- Joining - a quarter of an inch.

2. Grundfos

Reliable pressure switches from a Danish manufacturer with an impeccable reputation "GRUNDFOS".

Feature

- High degree of protection (IP52). Such products are suitable for installation even in places with excessive humidity (wet basements, caissons and so on).

- Reliability in work.

- Some modifications (for example, FF 4-4 or 4-8) are low-current devices. They cannot be directly connected to the industrial voltage / voltage network, only through the "intermediate link" in the form of a special device (converter).

- An impressive assortment. Relays differ mainly in the value of the upper limit of operation.

Many experts are of the same opinion - most of the cost of the Grundfos pressure switch is accounted for by brand recognition. An analysis of the operation of such automation shows that domestic analogues are in no way inferior to the "Danes", although the price is much lower.

3. Condor

This is an example of German industry, which has won many sympathies due to the reliability of the work.

Features

- Pressure switch - bipolar. That is, when triggered, both circuits open simultaneously (phase and zero), which makes the operation of the system more secure.

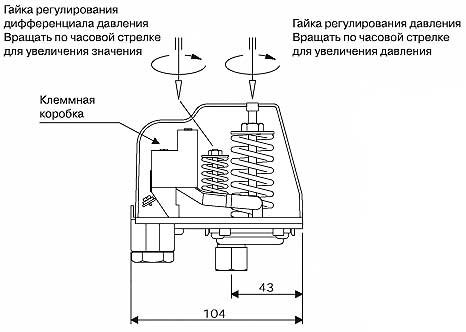

- Adjustment is made by rotation.

- Versatility of settings.

- Connection of a manometer is possible.

- The cost is high.

4. Danfoss (KP1 series)

Pressure switch from a well-known Danish manufacturer. It is expensive, but the high price is justified.

Features

- Gold plated contacts. Therefore, “sticking” is excluded.

- Existence of a adjusting scale allows to do without the showing device (manometer).

This Chinese product is often confused with a dry-running relay, although its purpose in the circuit is completely different. The only plus is low cost.

But such a "cheapness" has a downside. Here are just the main shortcomings that are noted by users on thematic forums.

- Contacts are not silver plated (regular). Therefore, due to their burning, the circuit may not open at the right time.

- Moisture and dust protection are zero.

- They do not work out the guaranteed service life - they break down quite quickly.

6. ITALTECNICA

Relays of the Italian manufacturer. Together with pumps modification PM / 5 is used. Attracts not at a high price with excellent quality and reliability. It is mounted in the control circuit of the HVS circuit. Pressure Control Limits ( bar) - from 1 to 5 (lower / upper). The warranty is small - only a year.

If the station is not installed in the water supply system, but a station, then it is equipped with a modification G. Its main difference - within the settings - from 1.4 to 2.8.

- Contact group - copper lamellas.

- Non-stick coating - Ag-Ni layer.

- Plastic case with insulating gasket.

What to consider

You may encounter a situation when the settings are lost or the pressure switch is out of order. This is easy to notice: either the pressure in the water supply has decreased, or the pumping station does not turn on at a given lower pressure limit.

Mechanical pressure switch automates operation pumping stationby controlling the on / off of the pump to maintain a stable pressure of water in the pipeline. The factory default settings are set: shut-off pressure 2.5 - 3.0 atm., Switch-on - 1.5 - 1.8 atmospheres (depending on the manufacturer). If you notice problems with the water pressure in the house, you must responsibly approach the setting of the pressure switch, since there is a direct relationship between the setting of the relay, the volume of the accumulator and the pressure.

Setting the pressure switch begins with checking the pressure of the compressed air in the accumulator. In this case, the pumping station should be disconnected from the mains and the accumulator tank should be empty. To do this, unscrew the side cover on the tank (see the figure - red arrow) and use a conventional automobile pump with a pressure gauge to check the pressure. It should be about 1.5 atm. If the measured value is less, the pressure must be raised by the pump to the required level. It should be noted that the air in the tank should always be under pressure, and when operating the pump station, it must be checked and pumped up from time to time if necessary, which will increase the service life of the accumulator membrane.

If, after adjusting the pressure in the accumulator, the pump station does not work in the normal mode, it is necessary to proceed with the adjustment of the pressure switch itself. It should be remembered that the pump shut-off pressure (upper setting) must not exceed the pressure that the pump can develop!

Setting the pressure switch RDM-5 pump station

The pressure switch RDM-5 is configured in a working system under pressure. To do this, turn on the pumping station and allow the pump to increase the pressure in the system, after which the relay will trip and the engine will turn off.

1) Remove the relay cover and completely loosen the clamping nut of the smaller spring.

2) We adjust the required minimum pressure (turning on the pump). To do this, rotate the clamping nut of the larger spring (clockwise - increase the pressure and vice versa). Then we open the tap and allow the water to drain, while the pressure in the system decreases. We look when the pump turns on and, if the result does not suit, we adjust further until we achieve the desired result.

3) In the next step, set the pump shut-off pressure (upper limit). Rotating the clamping nut of the smaller spring, we set the desired value of the upper pressure. We proceed as follows. Turn on the pump, wait for the relay to operate. If the shutdown pressure is not satisfactory, lower the water, adjust the spring and repeat the process.

So we set up the pressure switch.

Repair of the pressure switch of the pumping station (video)

What to wish if the relay is not configured? It probably failed. There are two ways to solve this problem: buying a new relay or repairing an existing one. In the first case, we advise you to take a closer look at modern and inexpensive pressure switches - pointer or digital.

For those who do not want to change an already obsolete relay for one reason or another, we recommend using methods.

You will find the detailed repair procedure in this video:

Typically, the pressure switch is initially adjusted by the manufacturer to a specific on and off pressure. These are the so-called factory settings, which most often have values \u200b\u200bof 1.5-1.8 bar (on) and 2.5-3 bar (off). But sometimes, during operation, additional adjustment of the pressure switch of the pumping station (turretless) is required, and we will consider how to do this with our own hands in this article.

Design and principle of operation of the pump station pressure switch

Before you start adjusting the pressure switch, it will be nice to get acquainted with its design and principle of operation.

Structurally, the relay of the pump station, most often, is a metal base to which a membrane cover is attached from below (under it there is a membrane and a metal piston) with a quick-detachable nut for fastening to the pump station adapter, and on top is a contact group, terminal block (for connecting the network, pump and ground) and two spring regulators of different sizes. All this is covered from above with a plastic cover, which is attached to the screw of the large regulator and which, depending on the model, can be easily removed with a screwdriver or wrench.

Structurally, the relay of the pump station, most often, is a metal base to which a membrane cover is attached from below (under it there is a membrane and a metal piston) with a quick-detachable nut for fastening to the pump station adapter, and on top is a contact group, terminal block (for connecting the network, pump and ground) and two spring regulators of different sizes. All this is covered from above with a plastic cover, which is attached to the screw of the large regulator and which, depending on the model, can be easily removed with a screwdriver or wrench.

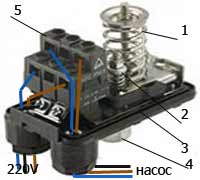

In Fig. 1: 1,2 - spring regulators; 3 - base; 4 - a nut of fastening of the relay to an adapter and a membrane cover; 5 - terminal block for connecting 220V network, pump and grounding.

Depending on the manufacturer and model, the relays may differ in size, shape, arrangement of constituent elements, but for the most part they have the above construction. Sometimes it includes additional elements, for example, a lever for protection against “dry running” or others.

Operating principle

The principle of operation of this relay is based on the fact that under the influence of water pressure that is supplied from the pump, the membrane presses on the piston, which drives the contact group mounted on a metal platform with two hinges. Depending on its position, the contacts to which the voltage 220V and the pump are connected, can be closed or open, respectively, the pump will turn on or off.

The spring of the large regulator acts on the platform of the contact group, balancing the pressure of the piston. As soon as the pressure weakens, under the action of the spring, the platform lowers and the contacts close (the pump turns on).

The spring of the small regulator also acts against water pressure, but it is located further from the hinge of the platform and does not enter into operation immediately, but when the platform with contacts rises to a certain height.

A small hinge with a spring is responsible for the operation of the electrical part of the relay (closing and opening contacts). It is structurally arranged so that the platform and this hinge cannot be in the same plane. As soon as it rises above the hinge, the contacts jump abruptly down, and as soon as it falls below its plane, they immediately snap up. The plane of this hinge is slightly higher than the base of the spring of the small regulator, which allows the platform to rise to this level without opening the contacts, and as soon as it reaches it, the contacts open under the action of the springs of both regulators and the pump turns off.

Thus, the large spring regulator is responsible for the moment the pump is turned on or the so-called “lower” pressure (P), and the smaller one for the difference between the on and off pressures (∆P).

When compressing the spring of the large regulator (tightening the nut clockwise), it acts with greater force on the platform of the contact group and the "lower" pressure increases. If this does not change the compression ratio of the spring of the small regulator, then the “upper” pressure (shutdown) will also increase, by exactly the same amount (since ∆P will be unchanged in this case).

When compressing the spring of the smaller regulator, the “upper” pressure will increase while the “lower” pressure is constant, that is, ∆P will increase. With the weakening of the springs, respectively, the above indicators will decrease. This is the basis for the adjustment of the pressure switch of the pumping station.

How to adjust the relay yourself

![]() If you, for whatever reason, are not satisfied with the factory settings of the pressure switch of your pumping station, then you can completely adjust it yourself. For this, a screwdriver or 10 wrench is enough to remove the relay cover (depending on its model) and a wrench to tighten (unscrew) the regulator nuts. The location of the nut for removing the cover is shown by the arrow in the photo on the right.

If you, for whatever reason, are not satisfied with the factory settings of the pressure switch of your pumping station, then you can completely adjust it yourself. For this, a screwdriver or 10 wrench is enough to remove the relay cover (depending on its model) and a wrench to tighten (unscrew) the regulator nuts. The location of the nut for removing the cover is shown by the arrow in the photo on the right.

The first thing to do is disconnect the relay from the voltage. After that, remove the plastic cover of the relay and adjust it depending on what its purpose is: to increase the pressure, lower or change the response range.

Having removed the cover, we will see two spring regulators under it. As previously stated, the large regulator is responsible for the switching pressure, that is, the “lower” that will be in the water supply network of our house, as well as the “upper”, with constant ∆P (if we do not touch the smaller regulator).

Increase or decrease network pressure

Thus, if we just want to increase or decrease the pressure in the network without changing the range of the relay, we simply twist or unscrew the nut on the larger regulator.

Thus, if we just want to increase or decrease the pressure in the network without changing the range of the relay, we simply twist or unscrew the nut on the larger regulator.

After we, therefore, have changed the adjustment, close the lid, turn on the voltage, open the tap and use the manometer of the pump station to determine at what pressure the pump is turned on (“lower”). Turn off the tap and check the “top” gauge - at the time the pump is turned off. If such indicators satisfy us, then the adjustment is over. If not, repeat the whole procedure.

Change the relay response range

If we are satisfied with the “lower” pressure, and we only want to increase or decrease the “upper” one, then for this we use a smaller regulator. When the nut of this regulator is twisted clockwise, the “upper” pressure will increase, while the “lower” pressure will be unchanged, and when unscrewed, it will vice versa, that is, the difference between them will increase or decrease - ∆P. After we have changed the adjustment, turn on the power and notice on the pressure gauge the moment the pump is turned off - the “upper” pressure. If it suits us, then we stop the adjustment on this, if not, we repeat until the desired result is obtained.

It should be noted that an increase in ∆P will allow the pump to turn on less frequently, but pressure differences will be more noticeable in the water supply network, a decrease, on the contrary, will help to equalize it in the system, but the pump will turn on more often, which may lead to a decrease in its service life.

If at the same time we are not satisfied with the “lower” pressure (switching on) and the range of operation of the relay, then first we carry out the adjustment with a large regulator, and then with a smaller one, controlling the entire process by the station pressure gauge.

Things to consider when adjusting

When planning to independently adjust the operation of the pump station relay, you must not miss some important points:

- You can not set the "upper" pressure, which is more than 80% of the maximum for this model of relay. It is usually indicated in the instructions or on the package and, most often, is 5-5.5 bar (atm.). If you need to set it to a higher level in the system of your home, then you need to choose a relay with a large maximum pressure.

- Before you increase the pressure on the pump ("upper"), you need to look at its characteristics, whether he can develop such a pressure. Otherwise, the pump, being unable to create it, will work without shutting down, and the relay will not turn it off, because the set limit will not be reached. Typically, the pump head is given in meters of water. About 1 m water Art. \u003d 0.1 bar (atm.). In addition, it is necessary to take into account the hydraulic losses in the system.

- During regulation, it is not necessary to tighten the regulator nuts to failure - the relay may cease to operate at all.

Pressure in the accumulator tank and adjustment of the relay

The air pressure in the accumulator of the pumping station affects its normal operation, but has nothing to do with the adjustment of the relay. In any case, the relay will operate when the “lower” and “upper” are set, regardless of the presence of air pressure in the tank.

The lack of air in the membrane tank will only lead to the fact that it will be completely filled with water and (since the liquid is practically not compressed) the pressure in the system will increase to the “upper” pressure instantly and the pump will turn off immediately after the water intake stops. Each time the tap is opened, the pump will immediately turn on, as it will immediately fall to the “lower” one. That is, the relay will operate the same way as in the absence of a hydraulic accumulator. Reduced air pressure will cause the membrane to stretch greatly, and increased - insufficient filling of the tank with water, as excessive air pressure will displace water.

In order for the pump station to work normally and the membrane to serve for a long time, the air pressure should be 10% lower than the “lower” (inclusion), which you set during adjustment. Then the accumulator will be optimally filled with water, and the membrane will not stretch too much and fail, and the pump will turn on at intervals that will correspond to the ∆P adjusted in the relay.

Modern water supply systems are designed to provide uninterrupted water supply to the consumer, and from the tap it must be supplied under a certain pressure. This is ensured by special automation units consisting of a hydraulic accumulator and a water pressure switch.

The hydraulic accumulator is a reservoir (membrane tank) in which a pear-shaped or rigidly fixed flexible membrane is located. Both that and another membrane divide the reservoir into two chambers: water and air, in which there is compressed air.

The membrane tank is used to create excess pressure in the water supply network and compensate for possible hydraulic shocks. In addition, it provides the necessary supply of fluid.

Under the action of a pump (supercharger), water enters the water chamber. At the same time, its volume increases, respectively reducing the volume of the air chamber and increasing the pressure of the compressed air inside it.

At a certain pressure, the pump switches off. When the consumer opens the faucet, water flows out of the reservoir (hydraulic tank) with a certain pressure, which is created by compressed air acting on the membrane.

Over time, the pressure gradually decreases to a critical value, after which a supercharger is turned on, which pumps the required amount of liquid into the tank. This process is repeated cyclically, and it is the water pressure switch that ensures the operability of the entire system without outside interference.

Types, their advantages and disadvantages

Electronic relay

The industry produces several types of water pressure switches for pumps.

Among them are distinguished:

- mechanical;

- electronic;

Electronic devices operate more reliably and more accurately than mechanical ones. At the same time, they provide more precise adjustment of the range of thresholds. In addition, all of them are equipped with a flow sensor, which block the operation of the pump in the absence of water in the system (“dry running”).

There are also mechanical devices equipped with dry run protection systems. However, in systems with such devices, after the appearance of water, the pump must be started manually, and electronic ones turn it on automatically. To do this, they provide a test mode for fluid movement (the pump is regularly turned on for 15 seconds and the sensor monitors the fluid movement).

In addition, many electronic components are equipped with a built-in hydraulic accumulator with a capacity of up to 0.4 l, which protects the pump from water hammer at the moment of its inclusion / switching off.

Another drawback of mechanical relays is the rather complicated adjustment of the thresholds, which requires disassembly and the use of wrenches. To configure the electronic does not even need a screwdriver.

The only advantage of mechanical relays over electronic relays is their cost. The difference in price can reach several thousand rubles.

DIY installation and configuration

Adjustment

Installing a relay for a water pump is not difficult, but it has a number of features:

- Experts advise installing the relay directly near the accumulator. It is there that pressure surges are leveled during switching the pump on and off.

- Some models have environmental restrictions. They must be installed in heated rooms.

- When connecting the device to the water supply system, in general, it is advisable to install before it:

- inlet valve;

- filters for rough and fine water purification;

- check valve;

- drain into the sewer;

- Almost all modern pumps have integrated water filters and check valve. In addition, they are equipped with special fittings for connecting a pressure switch. Therefore, if the relay is made in a waterproof housing, it can be installed with the pump directly in the well.

- In order to reduce the wear of the elastic membrane, it is necessary that the pressure of water in the water supply system is 0.2 atm. was greater than the pressure of compressed air in the air chamber of the membrane tank.

- Having finished connecting the device to the water supply system, proceed to the electrical connection:

- First, an electrical network of 220 V is connected. The wires must correspond to the power of the relay.

- Then connect the pump to the corresponding contacts of the product.

- It is necessary to pay attention to the fact that the relay can be power (switches the power contacts to the pump) or by the manager (gives a signal to the control unit). After carrying out the above work, the system is ready to work.

If necessary, do-it-yourself relay settings can be done.

Relay setting

For this:

- Determine the range of variation water pressure (differential).

- Turn off the product from the electrical network.

- Remove the top cover.

- Set the required threshold values using two special spring-loaded adjusting screws located under the cover. The value of the set values \u200b\u200bis controlled using a manometer. Wherein:

The adjustment of the upper threshold, at which the pump is turned off, is carried out using the adjusting screw indicated by the symbol "P". To change the trigger threshold of the actuator, it is necessary to rotate the screw in the direction of the arrow corresponding to the notation “+” and “-“.

The lower threshold of operation, at which the pump will automatically turn on, is adjusted by rotating the second adjustment screw with the “5P” symbol in the direction of the “+” and “-“ designations;

Device

Structural elements

The device controls the amount of fluid pressure in the water supply network and maintains it at a given level. The smooth functioning of the entire system as a whole, as well as its individual elements, depends on the quality of its work.

The relay in general is a device (block) with special springs installed inside, with which the values \u200b\u200bof the minimum and maximum threshold and two pairs of contacts that are used to connect the electrical network and pump are set.

The plumbing system is connected to it through a threaded hole, the diameter of which is 1/4 inch. The water part of the block is separated from the mechanical elastic diaphragm. The fluid presses on the diaphragm, which acts on the respective springs.

One of the springs - the minimum pressure spring - counteracts fluid pressure. The stronger it is compressed, the greater the pressure of water is necessary for the relay to operate.

The second spring - the pressure differential spring - sets the range of variation of the fluid pressure between the boundaries of the relay. The stronger the spring is compressed, the greater the difference between the upper and lower threshold.

The principle of operation and scope

Operating principle

The operation of the device is ensured by the fact that the movable springs installed in the device’s body constantly monitor the water pressure in the system, if necessary turning the blower on or off.

Wherein:

- When a potential consumer opens a tap, then water comes to him from the hydraulic tank. The necessary pressure is ensured by the pressure of compressed air in its air chamber.

- As the amount of water in the tank decreases, her pressure gradually drops. When the minimum value is reached, the electrical contacts of the relay are closed, the pump turns on and supplies water to consumers directly, bypassing the membrane tank.

- When the consumer closes the tap, the supercharger pumps water for some time, again filling the water chamber of the tank. The pressure in the tank rises and reaches the maximum permissible value. At this moment, the relay contacts open and the pump turns off.

Water pressure switches are used in various water supply systems.

They serve to automate the operation of the water pump and, in general, provide:

- Automatic circuit recharge water supply.

- Water level monitoring in tanks (automatic emptying or tank filling).

- Maintenance of the set value of working pressure in membrane tanks of water supply systems.

- Water blower protection from the dry run.

- Other tasks, in cases where load control is required in a given pressure range in water supply systems.

Specifications

Existing models are available already adjusted in accordance with current standards. These settings are optimal and, as a rule, do not require changes.

Most often, relays can maintain the working pressure of water in the range of:

- 1.4 to 2.8 bar (factory setting);

- 1.0 to 5.0 bar (manual installation);

In this case, the difference between the lower and upper threshold (differential) is from 1.0 to 2.5 bar.

In addition, all products have the following technical characteristics:

- Supply voltage, B - 220.

- Amperage, And no more - 12.

- Permissible water temperature, degrees Celsius - from +5 to +35.

- Maximum ambient temperature, degrees Celsius: +45.

- Criterias of choice.

Choosing the right product is not an easy task.

To do this, a potential buyer should imagine:

- Wednesdayin which the device will work.

- Required Setting Range differential.

- A set of additional features.

It is also necessary to pay attention to:

- Availability of installation.

- The presence of waterproofing.

- Correspondence of power of the pump motor to power contact groups.

- Possibility of independent adjustment parameters.

Cost and Manufacturers

Relay TM Grundfos

The cost of the relay is in a fairly wide price range and is determined depending on:

- Device type (mechanical or electronic).

- Brand of the manufacturer.

- The presence of additional features.

So, the cost of mechanical relays of various brands is:

- TM Grundfos (Germany) with a differential of 0.2 to 8 bar - 4500 rubles.

- TM Danfoss (Denmark) with a range of settings from 0.2 to 8 bar - 3000 rubles.

- TM Italtecnica (Italy) - 500 rubles (standard settings).

- TM Dzhileks (Russia) - 300 rubles (standard settings).

At the same time, the cost of electronic devices, depending on the manufacturer, is:

- DPS-15A (China) - 1417 rubles.

- Brio TANK (Italy) - 3625 rubles.