How to disassemble a submersible pump. Well submersible pumps "Vometomet" and its repair

Recently, pumps for wells have become popular. As soon as they appeared on the market, they became in great demand all over the world.

Even the most common pump models often fail. Pumps will have to be repaired as soon as possible. If you do not take measures, then without water in the country, or country house You will have to sit for a very long time. For example, take pumps from the company Gileks.

1 The most common pump failures

We all know that a pump is an ordinary device, a mechanism that is not difficult at all, but this is a judgment only at first glance.

The pump consists of an engine, an impeller, and also in the middle of the pump there is a shaft, seals and all this closes the case. The above details are constantly in operation, which leads to gradual wear.

That's why it is necessary to repair the pump occasionally, since the device is constantly in operation and is in the water. Yes, not all pumps work in water, for example, such as Gileks surface pumps, which work on the surface at the same time as hydraulic accumulators, which can also be installed separately on the surface.

But, for Jilex surface pumps, repairs are also needed. Here we take for example such a well-known manufacturer as. This device is in the water (well or well) constantly. Some of us do not even take it out for the winter, and this is a gross mistake.

The pump Dzhileks Vodomet has a light design, and to repair it with your own hands is really simple. But if you are not an expert in this, you will not only not repair it, but you can even harm the pump even worse. But if the situation is such that there is a slight pump breakdown on the face, then you can do it yourself.

The main thing who is going to repair submersible and surface pumps is to understand their design, as well as how they are connected correctly. The most famous pump failures, which we will discuss in this article separately.

Check pumps are very easy and affordable.

- For example, if the pump is connected to 220 W and it does not respond, then there is a breakdown on the face with contacts or with a supply wire. They solve this problem easily, you only need to have a tester. He also checks the pump contacts. If there is no signal during the verification, then the contact is damaged.

- You should also pay attention to the contact, it may become damp or change color. If when connecting 220 W, all mechanisms do not respond, then the main cable is interrupted. This is the most common failure at Vodomet pumps. Their minus is that their cable is very weakly protected, and is constantly in a suspended state.

- If during operation you notice a rumble in the engine, uneven operation is felt, clicks are heard, this indicates that there are problems with the engine and the impeller of the pump. To finally understand this, you must first disassemble the pump and inspect it. It may be that the impeller of the pump just cracked and the bearings flew out or failed. These are the most painful problems of pumps.

- If you saw that the engine does not work at all, then the problem is in it. And in this case you will not be able to repair it with your own hands. Especially such a breakdown is found in submersible models. If we disassemble a specific model, take the example of the Vodomet 50/25 pump engine, then it is not repaired or disassembled at all. In them, most often the winding can burn out. But replacing the winding in such models is a moot point. It is better if you have such a breakdown, replace the engine with a new one, as Jilex manufacturers are constantly replenishing the range of spare parts.

If we talk about Gileks Jumbo, then in the surface of such pumps the engine often burns out and the engine quickly worn out. And it all happens from the dry running of the pump. Surface pumps break more often from dry running than for example submersible units.

Back to the Jilex Jumbo pump. It breaks down like poor water pressure in the system. The main reasons for this are: the pressure switch does not work and the accumulator does not work, as well as the general problems of the pump as a whole.

First, we will analyze the first breakdown, this is a relay failure.

Its performance is checked easily and simply, and if you notice that everything is not so smooth with it, it is configured very easily. If we talk about accumulators, then there are the following breakdowns:

Rupture of the air membrane. And you can check it only when we disassemble the tank. If there is a large amount of air in the membrane, then the system is completely unbalanced, as a result of which the pressure drops.

The pump itself may also react poorly, but this happens very rarely. Most often, the working elements come out of the pump, and the pump simply can not cope with its task, to pump water. And if the working elements of the pump come out, during operation you notice a hum, the impeller rotates poorly. If there are other signs of failure, then most likely a relay or hydraulic accumulator has failed.

2 We repair the pump depending on the model of the manufacturer

The time has come to consider in practice pump equipment. Here it is necessary to distinguish the repair of a submersible pump from the repair of a surface unit. First, consider the widespread model of the Vodomet pump. Such a water-jet pump belonging to the submersible model is available in several positions and configurations.

For example, configurations such as 40/50, 55 / 35,110 / 110. The main difference between them is the size and equipment. As a result, their design is the same. It is necessary to start repairing the Water Jet pump with its disassembly. To do this, the Vodomet pump is removed from the well, it must be turned off from the network and only dry should it be repaired.

Disassembly steps:

- As mentioned above, we dry the pump, then carefully remove the body and cover on the pump.

- Next, using a vice, remove the water intake mechanisms. Everything is done carefully, as the unit body is hollow.

- After that, you need to disassemble the pumping part, and if you find a breakdown there, then do it yourself with your own hands at that stage, it will not be difficult for you. If not, then move on to the engine.

- In order to take out the engine, it is necessary to carefully remove the snap ring, since it is plastic, and at the same time not to damage it.

- Then, as we got to the engine, we gradually draw out the wires, inspect them for burned wires.

- After that, if everything is normal, you need to add non-toxic oil to the engine and assemble the unit in the same order as they were disassembled.

Remember !! Oil must be filled harmlessly into the pump engine.

Glycerin is suitable for these cases; it does not pollute water. And after that, in a disassembled form, it is very easy to fix the pump problem with your own hands. If you notice broken contacts, then it is better to solder them, or wipe with an alcohol solution. And if the contacts are broken at all, then it is better to replace them.

If the problem is in the engine, then it is better not to repair it yourself, but to give it to a specialist who can give you a guarantee for his work in the future. As a result, we see that it is easy to repair the Vodomet pump and it will not be difficult for you. And most importantly, it does not matter what type of Waterjet you have chosen, since the principle of spare parts and the device are almost the same.

According to another principle of repair, a surface pump like Jilex Jumbo operates. It is much more complicated here, and it is necessary to solve the breakdown specifically. If you have a pump junk, then you must definitely repair it, remove the case and check all the systems in turn.

Work Stages:

- First, you need to disconnect the pump and the accumulator from the electricity of 220 watts.

- Then we drain the liquid that remains in the hose.

- We remove the case by unscrewing the bolts.

- Be sure to remove all moving parts of the housing, and only then disassemble the pump chamber.

- After that, remove the impeller and seals.

- Carefully pull out the engine.

- Now look at the wires. And after that, if everything is normal, we assemble the pump in the same sequence as we disassembled.

We remind you !!! that the problem with the breakdown of pumps is possible at any stage of disassembly.

The advantage of surface pumps is that their casing is not solid and can be removed in parts. Details in it are turned off and removed not sequentially, but this is a plus. Dismantled the pump and saw a problem with the impeller and consumables? They are not repaired, but are completely replaced with new ones.

If you decide to see the contacts, it is better to get there through the camera engine. To disassemble the accumulator, the hose is first disconnected, and then the plates are removed by unscrewing. Pull the membrane and inspect it.

Do not repair the relay tip with your own hands, since it is very vulnerable and can be easily damaged during repairs.

2.1 Do-it-yourself Dzhileks Vodomet pump repair - video

For water supply of a house or other structure where there is no central water supply, use.

The device is immersed in a water source. In frequent cases, a well is used as a source.

With the help of water is sucked and transported through pipes to consumers. As a result of the fact that the equipment is often located in water and works from the electric network, it sooner or later becomes unusable.

In this case, there is a need for its repair or complete replacement. As for the repair, in frequent cases you can do it yourself.

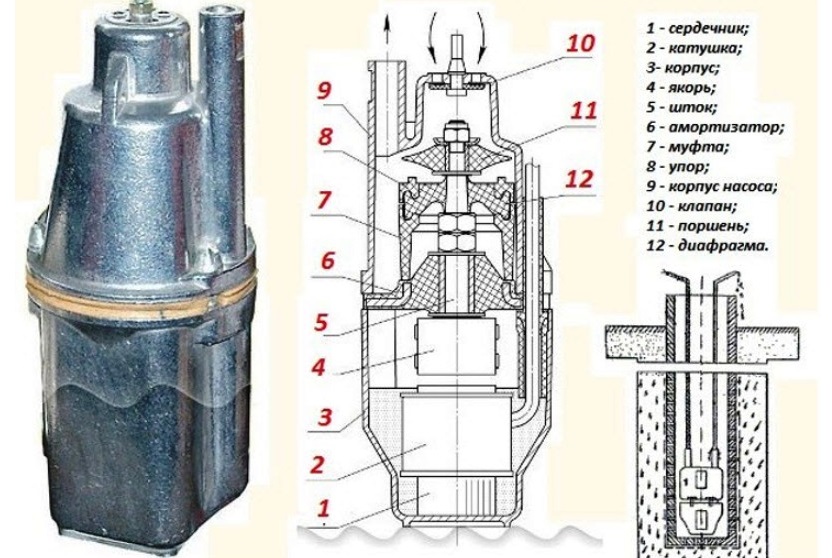

Device

The device of the deep pump. (Click to enlarge) Before starting repair work, it is necessary to carefully consider the device design, the principle of operation, and basic malfunctions.

The device of the deep pump. (Click to enlarge) Before starting repair work, it is necessary to carefully consider the device design, the principle of operation, and basic malfunctions.

This will make it easy to disassemble it. For water supply of private houses, centrifugal and vibration deep pumps are often used.

The first option is often used in wells, while vibration units are used in wells.

The deep centrifugal unit consists of these elements:

- case for the manufacture of which high-strength material is used;

- an electric motor ensuring the operation of the unit;

- impeller creating a centrifugal force that pushes water into the pipeline;

- bearings;

- cooling system and o-rings.

As for the vibration pumps, they consist of such structural elements:

- housing made of the same durable material;

- electric motor;

- working piston;

- high power electromagnet;

- shock absorbers and other small parts.

Each of these units has its own principle of operation. With information on the structure and principle of operation of the equipment, if necessary, it can be easily disassembled and carried out repairs. Of course, do not forget about the quality of the assembly. Often this parameter is of great importance in the operation and life of the equipment.

Specialist's Note: It is worth noting that vibrating pumps differ in low cost and reliability in work and are capable of pumping water of any quality.

Characteristic breakdowns

Disassembled submersible pump Often, a failure in the operation of the unit occurs as a result of mechanical defects.

Disassembled submersible pump Often, a failure in the operation of the unit occurs as a result of mechanical defects.

Not an exception is a malfunction in the control system of the device. Defects in turn can occur in two cases.

First of all, this may be the result of poor-quality assembly of the unit.

In this case, do-it-yourself repairs are not worth it. Often assembly defects are detected when the unit is first started. And this means that it can be immediately replaced with another pump with a warranty card.

In addition, mechanical defects arise as a result of frequent use of the pump. So, it can be wear or destruction of some structural element.

As a result of this, the following malfunctions can occur:

- A complete failure in the work or the supply of water under pressure, which does not correspond to the capacity of the deep pump A common reason for this is impeller wear.

- The appearance of large vibration during pump operation. Failure often occurs as a result of loosening of the connecting element, as well as wear of the bearings.

- Pump jammed. Occurs when a third-party object enters the unit or an increase in water temperature.

- A frequent problem is a leak in the equipment or at the junction of the pipe. The main reason is the wear of the o-ring.

Internal leakage is determined by the presence of rust. Check the pump for such a malfunction once every two months. If necessary, repair the breakdown immediately. Otherwise, this may cause the unit to be completely replaced.

In addition, other problems may occur. To carry out the elimination, it is necessary to know exactly the cause of their occurrence. Otherwise, you can simply lose time or do even more harm. Therefore, in such cases, it is recommended to seek the help of professionals.

How to disassemble

Clogging of a submersible pump Repairing a pump is a very complex and demanding process.

Clogging of a submersible pump Repairing a pump is a very complex and demanding process.

All work is carried out in a certain sequence:

- First of all, the unit is removed from a well or well. In this case, turn off the power.

If we are talking about a well, then to raise the pump you will need physical strength. Therefore, it is worth the help of friends or neighbors.

- When the pump is raised, you need to disconnect the pipes through which the water is transported.

- At the next stage, the unit is disassembled and its elements inspected.

- All worn and damaged parts are replaced.

- After that, the pump is assembled and tested in operation. This must be done before immersing it back in the well. During the repair, lubrication of the necessary parts is also carried out and their cleaning from contamination.

Practice tip: when choosing parts, it is worth using the help of specialists.

Control system problems

Damage to the power cable The failure of the downhole pump is associated not only with mechanical defects, but also with the occurrence of malfunctions in the control system.

Damage to the power cable The failure of the downhole pump is associated not only with mechanical defects, but also with the occurrence of malfunctions in the control system.

So, the reasons for this may be the operation of the unit outside of water, damage to the power cable and motor breakdown.

To prevent the unit from working outside the water, a special sensor is installed on it. When the water in the well or well drops below the minimum level, the sensor will signal and the pump will shut off. If this all the same happened, then only service specialists will be able to repair the pump.

Submersible pump "Vodomet" - this unit is on a par with the well-known "Kid" and "Brook" - brands whose name has been transformed into a proper name, which has designated a whole niche in the market of small-sized and simple pumps for stand-alone wells.

At the same time, all the aforementioned units attract the consumer not only with a moderate price and noticeable performance, but also with the ease with which repair work is carried out, restoring the pumps to work.

Therefore, in this article we will consider the repair of the pump Gileks Vodomet on the example of model 60/52. In a word, we suggest you evaluate the simplicity of the structural solution of this unit, and get acquainted with the secrets of its repair. Perhaps this will determine your preference when choosing a pump for an autonomous water supply.

Water Pump Well Pumps: Overview of Typical Design

The basis of any pump housing. And this part of the Vodomet unit is made in the form of a metal cylinder. It is in it that the engine is mounted, on the shaft of which they put the impeller.

Moreover, the impeller is separated from the engine compartment by a special insert through which the shaft passes. In turn, the impeller itself consists of a repeating set of disks, alternating in the following order:

1 - The first white disk with external blades, 2 - The first black washer, the same diameter as the white disk, 3 - The first "glass" with internal blades, 4 - The second white disk with blades, 5 - The second washer, 6 - The third white disk with blades, 7 - The second "glass" of the internal blades, 8 - The third washer, 9 - The fourth disk with the external blades, 10 - The third "glass" with the internal blades, 11 - The fourth washer, 12 - The fourth "glass" with the internal blades, 13 - Fifth washer, 14 - White plug with perforation in the center, 15 -

Black lid with a round hole in the center, 16 - Short cylinder with mesh at the bottom - filter element

|

|

This is how any Vodomet pump is designed. That is, a similar alternation of discs, washers and “glasses” is present both in models designed to work in a 5-meter water column (60/32, 150/30 series), and in devices immersed up to 20-40 meters (60 series / 52, 150/45). When assembling, a small anti-friction washer (blue and white) is installed between each element. All other elements - and washers, and disks, and "glasses" - are made of polyamide.

This pump is designed for vertical installation in the thickness of clean water, which is quite typical for all submersible units of the Vodomet brand. Moreover, its design is practically no different from similar products from another model range of this brand. Therefore, the repair procedure applicable to the 60/52 model can be extended to other pumps from.

Repair of the Vodomet pump 60/52: how is it done

Submersible pumps fail for three reasons:

- Firstly, in case of impeller siltation.

- Secondly, in the event of a break in the electric cable.

- Thirdly, in the event of failure of the engine compartment components (stator or rotor).

Moreover, when diagnosing a problem, one should be guided by the following rules:

- If the shaft rotates during the test start of the pump extracted from the well, then the impeller is the problem area. Clean it from sludge and the pump can be reassembled in the reverse order.

- If the pump does not even turn on, then you need to check (ring the tester) the power cable. If there is voltage at the terminals of the engine compartment, the cable is intact. Well, if not, then it will have to be replaced with a new one. Finding a cliff and fixing it by twisting or soldering is far from the best idea. After all, the tightness of the cable will still be broken.

- If the cable is okay, then the problem is in the engine. And the pump will have to be disassembled to the engine compartment, to remove and rewind the stator or rotor.

And in each case, the repair of the unit begins with a complete disassembly.

- A short cylinder with a perforated bottom is screwed from the end of the pump - a filter element that protects the impeller from siltation.

- Then, all washers, “glasses” and discs are removed from the pump motor shaft in the reverse order described above (in the design review of the impeller). Moreover, all the numerous elements should be laid on a flat section of the workbench in the order of extraction from the body. After all, the impeller consists of 16 parts. And this is not counting the same number of anti-friction washers.

- Further disassembly to the level of the engine compartment begins with the removal of the engine retaining ring that covers its cover. To do this, by blowing a mallet on the upper fitting, move the engine down, after which, pulling the cord, return it to its place. And after all the manipulations, the o-ring will remain in the “shifted” position. Next, the circlip is displaced by a blow with a screwdriver to the part closest to the body. The stopper warps, after which it can be removed.

- After that, you need to disconnect the wires by opening the cover of the corresponding compartment, and, wielding a screwdriver and a mallet, “knock out” the engine from the housing.

After removing from the housing, the impeller elements are washed and dried, and the engine is sent for diagnosis and repair to a specialized workshop. After cleaning the impeller and updating the engine, the assembly of the Vodomet 60/52 pump is carried out in the reverse order of the above.