Reverse osmosis membrane for water purification. What is permeate? Well-known manufacturers of reverse osmosis filters.

There is a separation of the initial water flow into two components: permeate, which is desalted water, and a concentrate - water with a higher salinity compared to the initial one. The percentage of permeate may vary depending on the performance of the industrial reverse osmosis system, the composition and temperature of the source water, the type of membrane elements used and a number of other indicators, and usually amounts to ~ 60-80% of the source water.

Disadvantages of the filter cartridge.

- Use is limited to the water you will drink and the cooking water.

- Filtering is ineffective if your water is very polluted.

- Water can be stored in the refrigerator, but consumed within 24 hours.

Compared to traditional methods of chemical desalination, systems that use industrial osmosis have slightly increased capital investments, but at the same time orders of magnitude lower operating costs. Membrane separation in most cases is the best method of water desalination in Moscow and St. Petersburg, as this eliminates the need for industrial wastewater treatment plants and special storage facilities for aggressive reagents, and negatively affects the environment.

These filters consist of more or less thin cartridges that need to be tailored to suit your needs. Anti-limestone cartridge: To handle your scale problems and extend the life of your washing machines. Refinement cartridge: removes particles ranging in size from 10 to 500 microns, such as sand, pollen, mold, sediment and other impurities suspended in water. Ultrafiltration cartridge: with a filtering capacity of 01 to 1 μm, it eliminates all viruses and toxins. Nanofiltration cartridge: for heavily polluted waters, the pore diameter of the membrane is from 01 μm to 001 μm. Save energy by preventing the scaling of electrical resistors, water heaters, and washing machines. Instruments A smart purchasing and maintenance solution that meets your needs.

- This is the last step before reverse osmosis.

- Purifies water and eliminates unpleasant odors.

- Prevents scale and eliminates existing deposits.

- Extends the life and efficiency of your appliances.

Membrane stations and industrial reverse osmosis systems of the ZauberROS series are designed for desalination of water using low-pressure reverse osmosis. All units are equipped with a microfiltration unit (filtration fineness 5 μm), a corrosion-resistant high-pressure pump, stationary control devices (conductivity meter, rotameters / flow meters, pressure gauges / pressure transducers), dry running and overpressure protection, as well as a flush block connection circuit (shut-off valves and pipelines). In industrial reverse osmosis plants of the ZauberROS-W and ZauberROS-S series, a reagent water treatment unit and a washing unit, equipped with a corrosion-resistant washing pump and a washing solution tank, are added to the delivery set.

It cleans tap water perfectly. It is useful and economical if you have an aquarium technique used to desalinate sea water. The cost is quite high and requires the intervention of a plumber for installation and maintenance. Other filters must be replaced every year.

Its use is highly recommended if you want to consume water that does not come from the network.

- It is often recommended to remineralize osmosis water before use.

- Up to 4 liters of water discharged per 1 liter of consumed water.

- Lowering your tap water flow.

- The osmotic membrane is very fragile and must be replaced every 2 to 3 years.

In reverse osmosis plants in Moscow and St. Petersburg, rolled membrane elements of leading world manufacturers (Hydranautics, Osmonics, FilmTec, etc.) are used. All wetted parts of assemblies and assemblies included in the set are made of stainless steel, polymer or other food-grade materials class. The strapping of industrial reverse osmosis plants is made of PVC.

Bacteriological treatment is very effective and environmentally friendly, without the addition of chemicals or organic substances.

- Installation is quite simple, it easily adapts to your distribution system.

- Maintenance and low maintenance.

- Supports the taste and character of the product. water.

Treated water cannot be stored for more than 36 hours, since there is a risk of bacteria remaining. Does not handle chemical contaminants and scale. . What tax benefits can you use? Applies to the entire invoice for products installed by qualified professionals.

There are several possible versions of the special design of ZauberROS osmosis membrane systems of series W and S):

1. Execution of "Plus". The reverse osmosis unit's frame structures are made of stainless steel (st3 painted steel as standard). Designation example: ZauberROS-6W +.

2. Execution of "eXtra". In the manufacture of the hydraulic circuit and structural elements, only stainless steel and plastic materials are used (galvanized and painted steel, brass, bronze are allowed in the standard version). Designation example: ZauberROS-6W-X.

Reverse osmosis occurs with the help of a semi-permeable membrane that is able to accurately filter water, obtaining optimal appetite characteristics. This process eliminates infinitely small contaminants, ensuring the absolute purity of water from a bacteriological point.

In the first phase of the filtration, water passes into a pre-filter of the precipitate, which filters up to 5 microns, excluding coarse substances that destroy the osmotic membrane. In the second stage, chlorine is used to disinfect water: since chlorine can destroy the membrane and give unpleasant odors and aromas, filtering is due to active carbon, which eliminates and protects the membrane.

3. Execution of "Nano". The industrial reverse osmosis system is designed to use nanofiltration membrane elements (reverse osmosis elements as standard). Designation example: ZauberROS-6W N.

Block membrane reverse osmosis plants of the ZauberROS series are manufactured with a given capacity of up to 200.0 m3 / hour or more. When choosing an industrial reverse osmosis membrane filter, the quality of the source water and the requirements for purified water should be taken into account. To increase the service life of the membrane elements, it is recommended to use industrial reverse osmosis equipment of preliminary preparation, the composition of which is determined by the technologist according to the quality of the source water.

Due to this, pure water flows through the drinker, and the drain is removed with residues and various substances through the check valve, which prevents its return. If necessary, water can be remineralized through a needle valve equipped with a scrubber, with already microfiltration of water.

This cleaner has intermittent operation and is not recommended for more than 15 minutes in case of continuous use. It is also easy to install, run, and maintain. The water that is supplied is clean and tastes good, good for eating, keeping the balance of body salt unchanged.

Temperature 5-35 ° C

Turbidity not more than 1 EMF (0.56 mg / l)

The presence in the source water of oil products, microbiological contaminants, as well as active chlorine or other strong oxidizing agents is not allowed.

* Subject to the conditions of the service life of the membrane elements of reverse osmosis equipment for at least three years.

Modern tap water is an environment that contains not only dissolved minerals and harmful inorganic impurities, but also pathogens that cause outbreaks of infectious diseases. In order to prevent poisoning and the spread of infectious diseases having a water transmission route, filtering installations are used in everyday life and in industrial conditions, which, despite the hopes placed on them, do not always cope with the task as efficiently as possible. In this regard, there was a need for the invention of specialized filtering systems that could be used to effectively remove harmful impurities from water, which scientists have managed very successfully by developing a project for a reverse osmosis water treatment system. Due to the fact that water purification by the reverse osmosis method is the most promising and reliable way to prepare drinking water, in this article we will consider the main operational characteristics of such systems and the detailed methodology for their installation.

This device can be installed horizontally or vertically even in a limited space and is equipped with an electronic board with a microprocessor for automatic operation control. Thanks to the membrane washing system, which takes place automatically after each water supply cycle, it can have an extraction rate of about 60% to reduce water consumption without compromising the functionality of the membrane, which has 3 to 5 years.

San Marco Osmosis Water Treatment Plant

Dirty water is pushed by external pressure through an osmotic membrane that contains impurities and excess mineral salts in addition to harmful substances to humans. It also has an autoflusher that maintains the purity of the osmotic membrane, providing greater purity of water and better functionality of the device.

Osmosis and reverse osmosis: a brief description of the concepts

Osmosis - the phenomenon underlying the metabolism of all living organisms and implying the entry of nutrients into the cell, and the excretion of metabolites from it. The implementation of these processes is carried out through a semi-permeable membrane, passing molecules of some substances and preventing the passage of others. If salt solutions with different concentrations are located on opposite sides of a semipermeable membrane, which is capable of passing only water molecules, it is reasonable to expect a leveling of concentration, which will lead to the movement of water molecules from a less concentrated solution to a solution with a higher concentration. The driving force in this case is osmotic pressure.

Thanks to the backlit display, you will know when to replace consumables. It is also equipped with a flood prevention system, automatic rinsing and is programmed to provide long membranes and a saline regulator that can be customized to suit your needs.

Membrane flushing is processed electronically and automatically to maintain their performance over time and the limited cost of replacing the filter every 6-12 months. This unit is also equipped with a backlit electronic control unit, which combines all the basic programming functions. It is implemented in accordance with serious international and Italian standards, using the most advanced technologies.

Reverse osmosis - the concept that occurs when a solution with a higher concentration is affected by external pressure, the value of which exceeds the osmotic pressure. In this case, water molecules move in the opposite direction, that is, from a more concentrated solution to a solution with a lower concentration. Thus, excess pressure, the magnitude of which exceeds the magnitude of the osmotic, “forces” water molecules to diffuse through the membrane in the opposite direction, opposite direct osmosis.

Reverse osmotic water purifier

Compact and compact design allows you to position both vertically and horizontally.

How to choose a reverse osmotic water purifier

A reverse osmosis water purifier is the most common filtration system through which food water is sanitized without the use of any chemical. Using a membrane, this device can return oligomineral water, which is purified by substances that can give off tubes, especially obsolete ones.

Reverse osmosis water purification: the principle of functioning of membrane systems

The method of water purification, which is based on the reverse osmosis process, has been used since the beginning of the 60s of the last century as the main method of desalination of sea water. To date, using such installations, hundreds of thousands of tons of bottled drinking water are produced per day, the effectiveness of which is not in doubt. Briefly, reverse osmosis filters can be described as follows: they are devices based on the innovative technology of water purification. If you do not go into details and discard all the technological nuances, then the water is filtered in them due to the presence of a special membrane designed to remove impurities in the dissolved water. Using reverse osmosis water treatment technology, you can purify water from particles whose sizes do not exceed 0.001-0.0001 microns. This range includes most of the impurities that can be found in water: hardness salts, dyes, small molecules, sodium ions, sulfates and nitrates. If, before the direct use of reverse osmosis plants, additional purification steps, such as micro-, ultra- and nanofiltration, as well as mechanical cleaning, are used, the cleaning efficiency with the help of reverse osmosis plants will increase significantly.

More precisely, external osmosis is possible due to a semi-permeable membrane, which allows only molecules like water to pass through and displace those that are of a different nature. In fact, it holds up to 99% of particulate matter and bacteria present. The reason why osmotic water is never free of salts, so it is not completely demineralized, only easier. When tap water has a significant percentage of harmful substances such as chlorides, phosphates, fluorides and chlorine, filtering is highly recommended.

The market offers numerous models of purifiers that use the reverse osmosis process, the more compact they cost on average. They are usually distinguished by underwater and oversized models. In this case, the dispenser is placed above the sink. Regardless of which filtration is used, it is recommended to use glass bottles, because under certain conditions, plastic can cause carcinogenic processes. It is also good to wash hot water bottles and water bottles at low temperatures.

Reverse osmosis photo

At the heart of the work of reverse osmosis systems are baromembrane technologies, according to which the driving force of the process is the pressure difference created on both sides of the semipermeable membrane. It is made from porous materials such as polyamide or acetate cellulose films, as well as hollow fibers. From the point of view of design features, there are two types of filter elements:

If you cannot keep water in the refrigerator, it is better to drink it on the day it was bottled. There are basically three more types of water purifiers: one with the addition of carbon dioxide; One that uses an activated carbon filter, which, however, cannot filter nitrates and bacteria, so this does not interfere with the hardness of the water; which uses a magnetic ion accelerator that eliminates limestone without any mineral filtration. In the best reverse osmosis purifiers, filtration is combined, that is, it also has activated carbon microfiltration.

- Hollow fiber;

- Roll.

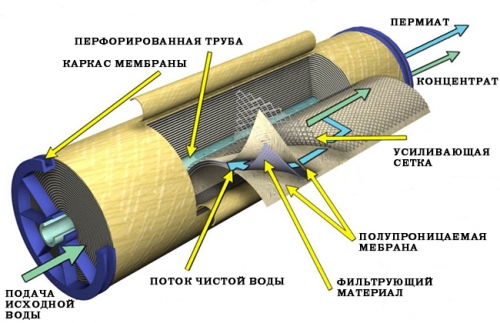

Important!In water treatment systems, the most common are reverse osmosis elements of the roll type, consisting of two semipermeable membranes and a layer of flexible elements of the tape type, which are wound on a central perforated drainage pipe. The source water subjected to purification enters the roll module and, due to the peculiarities of its structure, it is divided into two streams:

Most reverse osmosis models have a 5 micron pre-filter and a 5 micron activated carbon filter, then water passes through a 5 micron sediment filter and finally passes through the final microfiltration osmotic membrane. At this moment, the water drains: one part ends in the drain, and the other is purified, which we drink. Fees are available online as kits, which usually cost less than 100 euros.

The latest generation of cleaning products is so compact that they can be placed under a kitchen outlet. They are also elegant from time to time and are not expected to be overlooked; they are silent. Ultrafiltration products can withstand most of the contaminants in drinking water.

- Permeate - purified and desalted water passing through the membrane;

- Concentrate - water, characterized by a high content of impurities that have not passed through the membrane pores.

The structure of the filtration membrane and its functions

The filtration membrane is a composite polymer, characterized by uneven density and consisting of two layers that are inextricably interconnected. The thickness of the outer layer is 0.00001 inches. It has a barrier function and lies on a less dense layer with a thickness of 0.005 inches. A reverse osmosis membrane is a filter element that meets all the requirements, therefore, theoretically, in water passed through the membrane, regardless of the initial concentration of mineral substances in the water, no impurities should be present at all. In fact, in the water passed through the filter, there is a small amount of mineral impurities in a concentration of 6-7 mg / l, which also complies with the sanitary requirements for drinking water.

In addition, those who want to buy or change a reverse osmotic purifier, but are skeptical about the discussed demineralization problem, know that there are models with a bypass type that allows you to remineralize the osmotic water by reintroducing a minimum percentage of the water that has not been inspected. You will get bad water of mineral salts, that is, all oligomineral effects. Despite the fact that daily requirements for the mineral are limited only to water.

If our homes need more than one water filtration system, since tap water is usually rich in salts, it is true that reverse osmosis devices are also useful in environments such as offices, restaurants, bars, farms. It is especially recommended to use such a plant in areas with a high nitrate content.

The main function of the filtering membrane, as the name implies, is filtration, which is carried out through the pores of the material. Water passing through the filter membrane contains low molecular weight compounds and ions that are smaller than water molecules. Other impurities present in water, such as viruses, individual molecules, as well as dissolved salts and metal ions, are retained.

During the operation of the reverse osmosis installation, the surface and pores of the semipermeable membrane are gradually contaminated, which negatively affects the performance of the installation. To restore the initial operational characteristics of the device, it is necessary to flush the device, also called the regeneration cycle. The most common way to clean the surface of a membrane is to backwash it with a stream of water or purge it with compressed air.

Important!To increase the time interval between cleaning the device, experts recommend adding chemicals to the sewage stream that prevent the formation of sludge. The most commonly used reagents are sulfuric acid and / or inhibitor, which are added to the water after it passes through the pre-treatment unit.

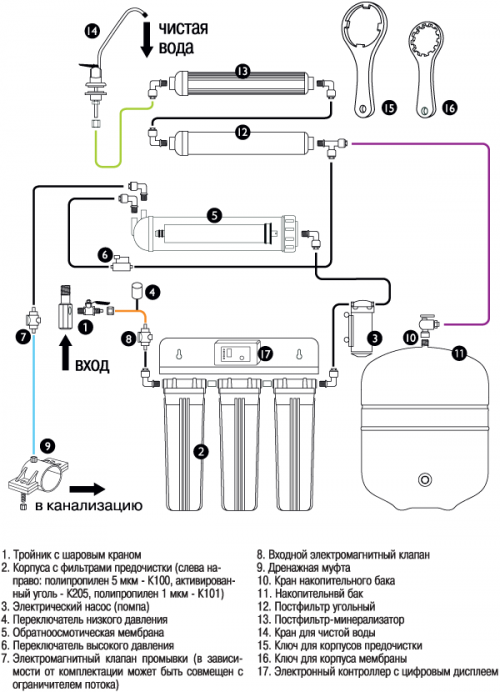

The main components of reverse osmosis plants

The composition of reverse osmosis water treatment plants is quite variable and depends on the composition of the water being treated, and the conditions in which this process is carried out. However, there is standard basic equipment, including the following functional elements:

- Pre-filterdesigned for pre-treatment of water, during which solid particles up to 5 microns in size are removed;

- Filter blockdesigned for mounting membrane modules that are directly involved in water filtration;

- Pump equipment, in other words, a pump for reverse osmosis, creating the necessary pressure difference, providing a reverse fluid flow;

- Strapping installation;

- Regulatory and instrumentationproviding control and automatic control of the reverse osmosis installation;

- Flushing unitdesigned to ensure flushing of the membrane surface at the right time in order to increase the productivity of the installation.

Additional cartridges that perform secondary functions and are installed in the system to improve the quality characteristics of water:

- Mineralizerdue to the use of which the water to be purified is saturated with minerals and salts necessary to maintain a normal salt balance in the body. In addition, water passing through reverse osmosis water filters has a higher pH;

- Ionizerdesigned to ionize water and remove negative ions. Water passing through filters with ionizers is characterized by easier absorption in the human body, contributes to the most optimal regulation of the pH level, as well as the removal of toxins from the body;

- Bioceramic cartridgerestoring the natural structure of water. The use of water passing through a reverse osmosis unit with a bioceramic cartridge helps to cleanse the body, remove toxins and slows down the oxidation of free radicals;

- Softening cartridgeBy setting which, you will get water purified from calcium ions, which is responsible for the hardness of the water.

Important! If you use a reverse osmosis unit with an additional cartridge, you must make sure that it has a double faucet designed for water that has undergone additional purification and water that has passed only through a reverse osmosis filter.

The process of water purification by reverse osmosis

The classical scheme of water purification using a reverse osmosis unit is a five-stage one and includes a sequence of steps, compliance with which is recognized as the main guarantee of effective water purification. The principle of operation of modern reverse osmosis plants is based on the passage of water that has undergone preliminary mechanical cleaning through a semi-permeable membrane, characterized by the presence of microscopic pores that trap contaminants, which are subsequently washed away by the flow of water into the sewer system. Preliminary mechanical cleaning is the first and necessary stage of water purification, since the largest particles falling into the pores of the filtration membrane can clog them, which will reduce the operational characteristics of the reverse osmosis unit, or completely disable it.

The pre-treatment stage involves the passage of water through the filter, which includes a cartridge system, and consists of several stages, which will be listed below:

- Coarse filterretarding large-sized mechanical particles (sand and rust);

- Coal block, intended for water purification from oil products, phenols, chlorine and heavy metals;

- Fine filter - the stage during which the final purification of water occurs, which involves the removal of particles less than 1 micron in size.

- In the fourth stage of purification, water passes directly through reverse osmosis membrane. At this stage, water is filtered through the pores of the membrane, the size of which helps to remove bacteria and other "small-caliber" impurities from the water;

- After the filtration of water through the pores of the reverse osmosis membrane, it accumulates in a sealed container made of metal or plastic, separated by a rubber membrane. On the one hand from the membrane, air is pumped into the container, on the other hand, water enters.

- After opening the tap, water is pushed out of the tank, after which it passes through the fifth stage of cleaning - carbon filter. After a five-step purification, the water becomes completely ready for use, has a pleasant taste and smell.

Important! The only drawback of reverse osmosis plants is the cleaning time due to their low productivity.

Benefits of reverse osmosis filters

- The highest level of water purification in comparison with other filtration units;

- No need to use additional reagents during the operation of reverse osmosis plants;

- Reverse osmosis plants are characterized by a compact layout of equipment included in their kit;

- On sale you can find many models of reverse osmosis filters, characterized by different performance and a wide range of operational characteristics, which allows them to be used both for domestic and commercial purposes;

- Ease of use and undemanding during operation;

- Automated operation of the installation is another advantage of reverse osmosis filters;

- Design features of such installations are also at the highest level. Their distinctive feature is a modular system, thanks to which you get the opportunity to increase the productivity of the installation with standard equipment by integrating additional filter cartridges;

- Piping and fittings of reverse osmosis plants are made of corrosion resistant materials, which also positively affects their operational characteristics.

- Before proceeding with the purchase of all the constituent elements for the installation of a reverse-OS installation, it is necessary to determine the water pressure in the pipe. If it does not exceed 2.5 bar, you must purchase a pressure boosting pump.

- In addition, it is important to calculate the amount of water that you need per day. It must be remembered that the performance of the membrane, which can clean from 50 to 100 gallons of water per day, determines the performance of the entire system.

- For the optimal selection of all filters and optionally built-in cartridges, it is recommended to perform a preliminary analysis of water, namely its mineral composition. A standard reverse osmosis unit includes three pre-filters, however, in the case of high quality water and its optimal organoleptic characteristics, their number can be reduced to two.

- In addition to the above elements, it is necessary to purchase a water flow restrictor, which is a tube with a calibrated hole and a plastic insert, which is designed to discharge the water flow into the sewer system.

To choose the right flow restrictor, you must take into account the performance of the membrane:

- A membrane that can clean 50 gallons of water will require a flow limiter of 300;

- For a membrane that cleans 75 gallons of water - 450 flow restrictor;

- For a membrane that cleans 100 gallons of water, a flow limiter of 550.

- To increase system performance, it is recommended to install a gearbox in front of the pre-filter.

- In the process of installing reverse osmosis filters, all components of the system must be connected using plastic tubes in the correct sequence, and FUM tape and tow with sealant should be used to seal the connections.

During the assembly of reverse osmosis plants, you will need the following materials:

Membrane and housing for it;

Filter system: mechanical filters, carbon filter, as well as additional filters;

- Storage tank;

- Reverse osmosis pump;

- Flow limiter;

- Pressure gauge for measuring water pressure;

- Cold water meter;

- Gearbox;

- Crane;

- Board for attaching filters;

- Two meters of small diameter pipe;

- Drain clamp on the hose to the sewer;

- FUM tape and tow.

How to install a reverse osmosis system? Key Points

- Due to the fact that there are several ways to install reverse osmosis filters, first of all, from all existing options, it is necessary to choose the most suitable for operation at home. The most common option is to install and connect reverse osmosis under the sink.

- Installation of the system can be carried out both vertically and horizontally. If you had to run out of space under the sink when placing the storage tank, it can be placed in the kitchen cabinet or in the side position, which will not affect the operation of the installation.

- In addition, the final water outlet must be connected to a separate faucet, which must be installed in close proximity to the sink or connected to some device, for example, a coffee maker.

Important! Filters with an integrated membrane and additional cartridges must be positioned so that during operation they are provided with convenient access for replacing cartridges.

- To ensure the removal of water into the reverse osmosis system, a tee must be inserted into the pipe with cold water.

Important! If it becomes necessary to install a booster pump, it must be placed so that it is located in front of the reverse osmosis semipermeable membrane, but after pre-filters. Such a placement of the membrane extends the life of the pump, as it does not become clogged with tap water.

- In this regard, the pump is powered from the mains, in order to avoid leaks and further short circuit, it is necessary to carefully seal all joints.

- In addition, care must be taken to install a four-way valve, designed to shut off the water supply in case of overflow of the storage tank. At one valve inlet, water is passed through a mechanical filter, and on the other, water is supplied to the reverse osmosis membrane.

- The remaining connectors are connected to the gap between the storage tank and the membrane. In the case of installation of a system in which there is no storage tank, both connectors are directed into the sewer system.

- To install the drinking water tap on the sink, it is necessary to prepare pipe clamps and fastening nuts. If there is no corresponding hole for the tap, it must be cut using a drill and a diamond-coated drill.

Important! When installing the filter, it is necessary to mount the clamp on the drain pipe, which should be located above the hydraulic shutter.

- After you have completed the installation, flush the system by flushing out some filtered water. To perform this manipulation, it is necessary to close the valve in the tank, and for some time to keep the valve open. Having fulfilled this condition, close the tap and open the tank. After it is filled, all water must be drained into the sewer. If you implement all of the above recommendations, you can be sure of the proper quality of the filtered water.

How to extend the life of the system? Cartridge replacement

- In the process of water purification at home, it is important to maintain the proper condition of reverse osmosis plants by timely replacement of consumables.

- Given the amount of purified water, the amount of which can be tracked by the meter, the replacement of mechanical and carbon filters must be done at least once every 3-6 months;

- The service life of the reverse osmosis membrane is also variable and, depending on the quantity, temperature and quality of water, varies from 1 to 5 years.

The need for membrane replacement can be judged by the following signals:

- Pressure reduction in the system;

- Deterioration of the quality characteristics of filtered water;

- The appearance of sediment in the membrane.

Important! If the cleaning system has not been used for a week, the membrane must be disinfected.