Installation of a second circulation pump in the heating system. Circulation pump maintenance and repair

Owners of autonomous heating for a long time no longer rely on the natural circulation of the coolant, forcing it to briskly run through the pipes with circulation pump.

Given that private homes are, for the most part, at a considerable distance from all kinds of workshops and service centers, it is very important for the owner of such a home to master the repair of a circulation pump for heating by himself.

A pump, like any other mechanism, needs periodic maintenance. Here's what the owner of such a device needs to do:

- In the warm season, when the circulation pump remains idle, turn it on monthly for 15 minutes. Of course, the device should not work idle: if the heating system is currently empty (many drain the coolant for the summer), you just need to pump water from one tank to another, connecting the pump to them using hoses. Such a measure will prevent oxidation of the shaft surface, which may result in its blocking. And the bearing due to such "training" will last longer.

- During the heating season, periodically pay attention to how the pump works. Are there noises, vibrations, or other signs of defect development? Does the unit maintain the required system pressure? Is the engine warming too much? Detecting a malfunction detected at an early stage is much easier than already severely malfunctioning.

- If a coarse filter is installed in front of the pump, it must be checked periodically for contamination, even if the system uses a prepared coolant (the filter may become clogged with rust that is washed off by the working medium from the pipe walls).

- It is also necessary to check from time to time whether the amount of grease is sufficient in those places where it is provided.

For idle time, the gaskets in the nozzles should be coated with preservative grease, which will prevent them from drying out.

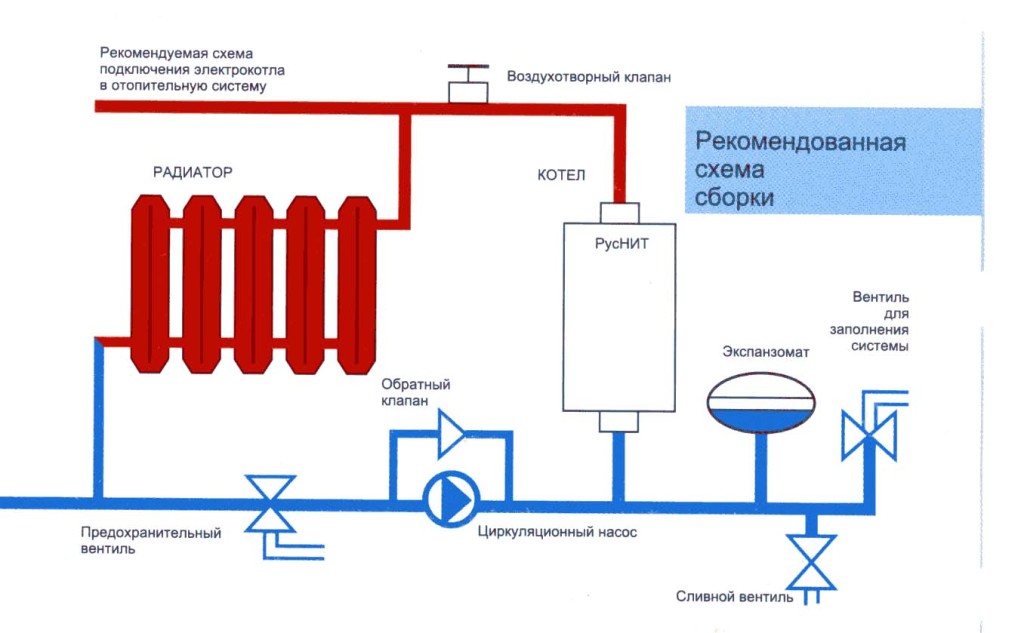

Make sure that the temperature of the coolant in the place where the circulation pump is installed (usually it is installed on the "return" in front of the boiler) does not exceed the permissible value.

The limit value is indicated in the instrument passport. For most models, the optimum temperature is 65 degrees.

How can you eliminate typical circulating malfunctions?

Even if you follow all the rules of operation and maintenance of the pump in the most scrupulous manner, failures may occur in its operation with a certain probability.Let's see how they can be expressed and what the user should do in a given situation.

So, the main malfunctions of circulation pumps and how to eliminate them.

The engine of the pump cannot be started, while no humming or other “electric” sounds are heard

In this case, the first suspect is a fuse, if, of course, is installed in your model. He sensitively reacts to voltage surges, which, alas, are not uncommon in the countryside, and at the slightest threat the engine melts, opening the electrical circuit. After replacing the fuse, the pump will return to working condition.

If the fuse turned out to be intact, you should “ring” the network cable and wiring, and also check the condition of the fuse or circuit breaker in the junction box. Perhaps he or some part of the wire needs to be replaced.

If everything is in order with the wiring, the winding of the electric motor may have burned out. Her condition is checked by measuring the resistance (use a multimeter). When connected to the contacts of the working winding, the device should show 10 - 15 Ohms.

If everything is in order with the wiring, the winding of the electric motor may have burned out. Her condition is checked by measuring the resistance (use a multimeter). When connected to the contacts of the working winding, the device should show 10 - 15 Ohms.

In addition to the working one, some pumps also have a starting winding. Its resistance should be 35 - 40 ohms.

If “infinity” is displayed on the meter display instead of the indicated numbers, then the tested winding has burned out. If the readings of the multimeter, on the contrary, tend to zero, then there is an interturn circuit. In this case, when you try to turn on the pump in the shield, fuses will blow.

The reason for the "strike" of the pump may be a breakdown of the non-polar capacitor present in the starting winding circuit. In good condition, it has a capacitance in the range of 10 - 40 microfarads. If the meter readings differ from normal, the part must be replaced.

You can take on an independent repair of the electrical part, having sufficient experience in such a matter. In most cases, experts have to be trusted.

Pump is buzzing but impeller shaft does not rotate

In such a situation, the pump must be turned off, otherwise the motor winding may burn out. There may be several reasons for the occurrence of such a breakdown:

- As already mentioned, the shaft may be jammed due to prolonged downtime. Also, the impeller, which does not work for a long time, can stick to the casing. In this situation, you need to disassemble the pump and rotate the shaft forcibly. In order for the user to be able to do this, there is a notch on the shaft, which you can catch on with a screwdriver. If you could not find it, disassemble the discharge mechanism and rotate the shaft, holding the impeller itself.

- The impeller may become blocked due to a foreign object entering the chamber. By deleting it, you will resume the system.

To prevent this from happening again, install a dirt filter at the pump inlet.

The pump began to be accompanied by an unusual noise

This is how air accumulated in the system can manifest itself. To remove it, it is most rational to equip the heating circuit with an automatic air vent. In the meantime, he will have to bleed the air manually. Immediately after this, the pump will stop making noise.

The pump vibrates a lot during operation

If you observe this phenomenon, it makes sense to check the condition of the bearing. Most likely, it is worn out and needs to be replaced.

If you observe this phenomenon, it makes sense to check the condition of the bearing. Most likely, it is worn out and needs to be replaced.

Bearings are always mounted on the shaft and in the bore with an interference fit, in other words, they are pressed in.

In factories and workshops for this they use a special tool - a puller.

House craftsmen who do not have such a contraption knock out bearings with careful blows of a wooden hammer or make a primitive puller on their own. It consists of a pair of plates with holes into which two studs with nuts are threaded. One plate rests on the shaft end, the other - on the bearing (it is put on the shaft, for which a hole of the corresponding diameter is made in it), after which it is necessary to tighten the nuts on the studs alternately and very gradually.

Pump vibration can also be caused by excessive cavitation. To solve this problem, it is necessary to increase the pressure at the inlet to the unit by raising the level of coolant in the circuit.

A heat pump for heating a living room is not the most common option, but it is great for economical heating. In this article, we consider the principle of operation of the unit and give an example of calculating the collector.

The pump does not provide the required head or a very short time runs, after which it immediately shuts off

The user may encounter such a nuisance if the electrical part of the pump was improperly connected or an unreliable connection of the contacts takes place.By confusing the contacts, you can even make the impeller rotate in the opposite direction (in units with a 3-phase motor), which is the reason for the pressure drop.

Having carefully studied the connection diagram given in the product manual, you will probably be able to detect an error and reconnect the pump correctly.

How to prepare circulation pumps for the winter heating season?

In anticipation of cold weather, it is necessary to bring the heating system to a state of alert. With regard to the circulation pump, do the following:

- Check the tightness of the connections between the pump nozzles and pipelines. If a leak is detected, tighten the nut or coupling slightly. If this does not help, you will have to replace the dry gasket or seal. With a lack of experience, it is better to use fluoroplastic (FUM-tape) or linen thread “Tangit unilok” to seal pipe threaded joints.

- If there is a strainer in front of the pump, check its condition and rinse if necessary.

- Ensure that the engine and bearings have sufficient lubrication.

- It will not be superfluous to measure the voltage in the outlet with a multimeter, through which the pump will be connected to the network. There are cases when electricians in rural areas, instead of a 2-phase voltage, supplied a 3-phase (380 volts) to the houses. The parameters of a normal 2-phase voltage may also differ from the norm. If the multimeter shows, for example, 235 V or 205 V instead of the 220, it is necessary to contact the appropriate service of the energy company.

If you have no complaints about the quality of the power supply and you could not find any coolant leaks, you should carry out a test run of the pump and let it run for a while. The absence of the above symptoms will indicate that the appliance is ready for the new heating season.

Related videos

In a forced circulation heating system, the circulation pump is the heart. The availability of heating and its quality depend on its stable operation. The same applies to closed hot water systems with a constant current of water in the pipes between the boiler and the storage tank. During operation, the question inevitably arises of how to perform maintenance and repair of the circulation pump so that it continues to work stably and without fail.

For the normal functioning of the pump, the following measures must be carried out:

- Correct operation, taking into account all the rules established by the manufacturer pumping equipment.

- Prevention and maintenance of the pump.

- Diagnostics and repair in case of pump failure.

The more accurately the operating rules are followed and the pump is regularly maintained, the less often you will have to think about repairing or replacing it.

A number of simple requirements apply to any circulation pump:

- The pump must not be allowed to run idle in the absence of water. Applies to wet and dry type pump.

- The pump must not be allowed to run with a stopped flow of water, for example, if a valve is closed before or after the pump.

- The optimal mode of operation should be determined taking into account the maximum and minimum throughput of the equipment.

- It is important to comply with the manufacturer's requirements for the nominal water pressure in the system.

- The temperature of the coolant should not exceed 65 ° C. Therefore, the circulation pump is installed on the return line in front of the boiler, where already cooled water flows. If the specified threshold is exceeded, the process of deposition of hardness salts on the internal surfaces of the pump is accelerated many times.

- Long downtime must not be allowed. About once a month or two, it is advisable to turn on the pump for 15 minutes. If this is not done, then the risk of jamming of the shaft increases during the oxidation process.

- It is not permissible to use a circulation pump for pumping dirty water with the inclusion of dense particles in suspension. A coarse filter must be installed, or the purity of water or coolant can be controlled in other ways.

In operating mode, the pump should have a uniform sound of a working drive and a constant pressure value at the output, which is controlled by the installed pressure gauge. With good handling, even the simplest circulation pump can last up to 5 years until its main elements wear out.

Design

Almost all centrifugal circulation pumps. They have an impeller mounted on the motor shaft and placed in a special “shell” chamber. The shell entrance is located in the center, while the outlet is the outer edge of the shell with a channel extending around the circumference in the direction of movement of the impeller. The engine spins the impeller, and water, under the influence of centripetal force, rushes from the center to the edges of the sink from the entrance to the exit.

Structural elements of the pump:

- a pump part, a sink and an impeller mounted on a shaft;

- electric motor;

- electronic control unit.

The movable part of the pump — the motor shaft and the impeller, as well as the bearings on which they are mounted — is most susceptible to wear.

Prevention and Maintenance

A long service life and trouble-free operation is possible only if the proper operating conditions and regular pump maintenance are observed. Maintenance refers to periodic inspection and cleaning of the pump. Inspection for deviations in work should be carried out at least once a quarter, that is, twice during the heating season. It is advisable to clean it once every two to three years, depending on the quality of the water and the conditions in which the pump operates.

During the entire period of operation, it is advisable to periodically check the operation of the pump:

- Connection points are checked for leaks. Upon detection, gaskets and seals are replaced (tow, FUM tape, etc.).

- The presence and condition of grounding is visually checked.

- The sound of a running engine should not be accompanied by clangs or blows, extraneous sounds.

- The engine should not vibrate much.

- Checks the pressure in the line and its compliance with the nominal.

- The housing must be clean and dry. If this is not so, then an external cleaning should be carried out, the electronic unit should be checked for gulf and the reason why the pump turned out to be wet should be eliminated.

About once every two to three years, it is advisable to clean the pump, including all its elements. This applies only to models with the ability to disassemble. There are pumps with a pressed-in or one-piece, welded housing, which do not require repair or disassembly. Such units fail and are then replaced with a new assembly. It is advisable to entrust this work to the service center. However, if you have the skills and the tool, you can do it all yourself

Required:

- allen key

- 4 and 8 mm slotted screwdriver (flat);

- phillips screwdriver.

Before disassembling the pump, water is drained from the system or a separate section in which the pump is involved is drained, dismantle it and then proceed with disassembly.

Procedure:

- 4-6 bolts around the perimeter of the motor housing at the junction with the shell of the pump part are unscrewed with a hex wrench or a Phillips screwdriver.

- Remove the shell, while the impeller will remain on the rotor shaft with the motor.

- Locate the four drainage holes around the perimeter. Using a narrow slotted screwdriver, a little at a time around the perimeter, pry the jacket of the engine compartment under the impeller. As a result, the shaft with the rotor and the impeller will come out of the grooves and the stator glass. You can help yourself if you unscrew the protective plug on the outside of the pump, insert a screwdriver into the slot on the shaft end and knock the shaft out of the thrust bearing with light strokes.

The analysis on this is completed. Now you should clean the surface of the rotor, impeller and the inner surface of the shell from plaque and scale, if any, without damaging the surface of the parts. Coarse abrasive is not acceptable. It is better to act with a brush with a polymer hard pile. Cleaning agents containing a weak solution of hydrochloric acid can help. In extreme cases, the smallest emery is applied - “null”.

For wet rotor pumps, it is important to check the cleanliness of the channel inside the shaft and the drainage holes located in the protective jacket separating the area of \u200b\u200bthe pump part and the motor. The fluid flows to the rotor just through these holes and then returns through the internal channel, if they are clogged, the engine cooling suffers.

For dry rotor pumps waterproofing of the thrust bearing is important. If a leak is detected from the pump unit to the stator unit, then completely replace all gaskets and seals inside the unit.

The condition of the bearings on which the shaft rests is checked. If they are already broken in order, they will need to be replaced, which is extremely difficult to do at home, you will have to contact a service center.

All seals and gaskets inside the pump should be checked for wear and replaced if necessary. As soon as all the elements are cleaned and checked, the assembly is performed in the reverse order.

Circulation pump cleaning required

Troubleshooting

According to how the pump, sound, vibration, or a change in pressure, output pressure, it is necessary to accurately determine the malfunction and eliminate the cause.

| Symptom | Probable cause | Repairs |

| The pump makes a sound after switching on, but the shaft does not rotate | Shaft oxidation due to long downtime | Unscrew the protective cap from the shaft end on the motor housing and manually rotate the motor shaft with a slotted screwdriver. |

| Foreign object blocking | Dismantle the pump unit with the impeller and clean, check the condition of the coarse filter installed in front of the pump | |

| Power Issues | Check the voltage rating of the network, if necessary, fix the problem. | |

| After voltage is applied, the pump does not start and does not make any sounds. | No actual power line voltage | Check power line and circuit breakers |

| The fuse in the control unit has tripped | Replace fuse | |

| The pump shuts off after a short run | Limescale in a stator glass | Clean the stator cup and motor rotor |

| Loud extraneous noise during pump operation | Dry running, air in pipes | Release air. Drain the pump shell and fill with water. |

| Cavitation | Increase pressure in the supply pipe. | |

| Pump vibration | Bearing wear | Bearing replacement |

| Reduced head and feed compared to passport data | Violation in the power supply of the pump, phase change, as a result of which the power of the pump decreases or the direction of rotation of the impeller changes | For three-phase motors, the quality of all phases is checked. For single-phase power supply, check capacitor; replace if necessary |

| High hydraulic resistance of the circulation circuit | Check filters, increase pipe cross-section, check condition of shutoff valves. | |

| External protection tripping on the pump supply line | Problems with the electrical part of the pump | Check the condition of the terminals for a short circuit, check the capacitor and the adjustment unit. Check stator windings. Their resistance should not be lower than the passport. |

Repairs

A broken circulation pump is best given to a specialized service center, especially if it is still under warranty. Most of the models currently on the market, unfortunately, are non-separable or partially collapsible, so if problems arise with its internal spare parts, entire units or the complete pump must be replaced. If the warranty period has already expired, and the design of the pump allows you to disassemble it and get to all the main components, then if you have the appropriate skills, you can repair it yourself.

Having determined the cause of the malfunction from the table above, it is enough to disassemble the pump, as indicated in the paragraph on prevention and maintenance, and replace the malfunctioning part.

The main elements in the pump control unit are:

- 1-5 microfarad capacitor;

- terminal block for connection;

- speed controller.

In view of the small capacitance of the capacitor, you can check it with a multimeter, in which there is a built-in C-meter with a limit of up to 20 microfarads. With a strong deviation of the readings from the nominal, the capacitor should be replaced, it is important to observe the polarity of the switch-on and its voltage tolerance is mandatory. Capacitors with a tolerance of up to 450 V are used for a conventional single-phase motor.

The speed controller is replaced with a new one. It is enough to disconnect it from the terminals, remembering the position of each pin and connect a new one.

The terminal block must be perfectly clean, dry and free from any signs of overheating or burns. If the above problems exist, then it should be replaced with a new one, the same or similar in the number of connections.

Popular are the circulation pump models from manufacturers Wilo, Ggrundfos, Dab. Not least due to their reliability. It is possible to expect that these pumps will break during the warranty period only if the recommended operating conditions are violated. However, in the post warranty period, Wilo often has a problem with the pillow block bearings. Only replacing them helps.

Ggrundfos and Dab can “please” with overgrowing of the impeller with scale for high-temperature heating systems, as well as siltation of the stator glass. It is better to prevent these problems by installing a good filter and preparing water. Otherwise, breakdowns are more often justified by external problems.

Pumps for circulating water in the heating system circuit are durable and practically not susceptible to breakdowns. If, nevertheless, a malfunction occurs, you can repair the equipment yourself. The equipment has a simple design, sets of parts for it are widely represented on sale. The fact that almost every circulation pump, regardless of model and manufacturer, is subject to the same types of breakdowns makes the situation easier.

Application features

Pumps are used in home heating systems in order to provide forced movement of the coolant along the circuit. This allows you to heat rooms of a large area when the pipes are so long that the natural flow of liquid is difficult.

Sometimes the water moves so slowly that it has time to cool down before it enters the boiler for the purpose of reheating. Specially for solving such problems, a circulation pump was developed.

To avoid damage, you must adhere to the following rules:

- do not turn on the equipment idle when there is no coolant in the system circuit;

- do not use the pump at zero flow;

- prevent excessively low or high fluid flow;

- heat the coolant in the system circuit to a temperature of no more than 65 ° C, otherwise the salts will precipitate. Even better is to fill the boiler and circuit with softened water;

- avoid prolonged downtime of the pump, and even in the summer season you need to turn it on for 10-15 minutes at least once a month to avoid blocking the shaft as a result of oxidation;

- before use;

- monitor the quality of power supply: there may be malfunctions in the network, including power surges.

Differences between malfunctions in dry and wet pumps

Dry pumps, whose rotor does not interact with water, suffer from a common problem for all models - damage to o-rings. This leads to a violation of the tightness of the working part of the rotor, and the liquid enters the motor. Then repairing the unit with your own hands becomes impossible, because due to a short circuit, almost all of its electrical elements will fail.

Suspension in the coolant and various particles in the air surrounding the boiler and pump become the cause of the destruction of the sealing rings. Also, rings can be damaged by natural wear: their maximum service life is 2-3 years.

Wet pumps are more convenient to maintain - they are designed in a modular fashion. However, this equipment quickly deteriorates due to start-up at zero flow or lack of coolant in the system.

“Dry” pumps are more enduring, they can tolerate such loads, although they wear out faster in unusual situations.

Diagnosis and prevention of breakdowns

It is possible to determine whether repair of the circulation pump is required by a number of signs. The easiest way is to turn on the equipment and check if it is noisy. Sometimes extraneous sounds are accompanied by a noticeable vibration. It is recommended that the pump motor does not overheat.

Check if the force of the water pressure in the pipe matches the parameters in the technical data sheet of the device. Features of the coolant circulation do not depend on what characteristics the heating boiler has, and are completely determined by the operational properties of the pump.

Visually inspect the housing of the pump unit to check for leaks. The most vulnerable point is the junction of the pipe with the unit. Check the condition of the gaskets and the fastening of the bolts, as well as the presence of grease on the threaded flanges.

Pay special attention to the electrical circuit: check the fixation of the wires, get rid of moisture in the electrical wiring and, if necessary, attach the case ground to the corresponding terminal.

Although it is necessary to contact a specialized service for breakdowns of the circulation pump, some malfunctions can be fixed with your own hands. For example, if the equipment is noisy and vibrating during operation, then one of the bearings is worn out. You can replace it yourself: these parts are sold in any city, and you can find out the required standard sizes of the part by looking at the technical data sheet of the unit.

If a sharp noise is heard when the device is turned on, this indicates the presence of air in the flowing part of the pipeline. If the coolant level is minimal, the pump may be harmed, especially if the unit is equipped with a wet rotor. The solution to the problem is to let the air out of the heating circuit and mount the air vent at the highest point of the piping assembly.

Sometimes the noise when turned on is accompanied by strong vibration, which indicates a low pressure in the suction pipe. In this case, you just need to increase the pressure force in this section of the pipeline.

Additional options

If the repair did not help and the pressure remains weak, then the pump is not installed correctly, so that the impeller rotates in the opposite direction. It is also possible that the circulation ring has a large flow resistance. Then the pump filter must be cleaned and then the diameters of the piping and control valves must be checked.

A long-used pump can start without noise and vibration, but stop working after a while. The reason for this is the presence of calcareous deposits between the stator “jacket” and the rotor, which are formed due to increased water hardness. The best way to get rid of a malfunction is to disassemble the pump and clean all the parts. At the same time, inspect the heating water boiler: a liquid with a high salt content could also damage.

Often the pump turns on, but its shaft cannot rotate. This means that the part is blocked by a foreign object or oxidized due to prolonged shutdown. In the first case, it is enough to dismantle the motor unit of the circulation pump and remove the item. In the second, everything is also simple: to carry out repairs, the wheel must be turned by hand or a screwdriver.

Remember: before removing the engine, disconnect the motor from the power supply and drain the water from the unit.

Solving Power Issues

There is another reason why the pump shaft does not rotate - a violation in the electrical circuit. In such a situation, it is required to check the supply voltage, which should correspond to the rating data, the presence of all phases and the correct connection of the terminals.

A phase check is also needed to eliminate such a problem as the operation of the external motor protection immediately after starting the unit. Sometimes the cause of blocking is the lack of grounding of the phase. If not, it is recommended to inspect the fuse contacts: they may be dirty or open.

Due to the fact that the pumps are designed according to the modular principle, defective parts of the electrical circuit can be easily replaced. The necessary characteristics of components are indicated in the technical data sheet of the device.

This article is devoted to the rules of operation and maintenance of equipment for pumping water used in heating systems. But before you figure out how to repair the circulation pumps with your own hands, you need to get an idea of \u200b\u200btheir design features and the principle of operation.

We hope that our instruction will fill in the information gap. And the video in this article on the topic: "DIY repair: circulation pump" - will help to cope with any problem that occurs during operation.

Pumps for heating systems

First, we answer the question: "What is a circulation pump?"

Its main task is to ensure the circulation or recirculation of water through the heating system. In the first case, it moves in a closed loop, and in the second - at different points of supply, and with partial losses.

Despite the fact that the circulation pumps move quite large volumes of liquid, they do not create a lot of pressure. Yes, this is not required of them.

According to the classification, they belong to the category of vane pumps, the most popular of which are: centrifugal, diagonal and axial.

They have a general principle of operation, based on the interaction of the pumped liquid with the blades of the working body. But the mechanism of this effect is different, and therefore their designs and operational qualities are different.

Centrifugal

In these pumps, it is mounted on a shaft and rotates freely inside the chamber. It consists of two parallel disks, and smoothly curved blades connect them together. When the engine starts, the discs begin to rotate in one direction, and the blades in the other.

Water flowing from the suction pipe into the inter-blade channels is ejected forcefully outside the wheel, creating a certain pressure. Liquid is discharged through a spiral chamber, and through the diffuser and nozzle is fed into the pipeline. The larger the diameter and speed of rotation of the wheel, the higher the pressure is created.

may have not one working body, but several, which, accordingly, increases the performance of the mechanism. But since the pressure is not so important in heating systems, a single-stage pump is enough for them.

Axial

Here is a completely different design of the working body. The wheel consists of a hub and blades fixed on it with a rounded edge.

The axial pump housing is a tubular chamber filled with water, inside which the wheel rotates. The liquid, in this case, moves along the axis of the sleeve, which is why this design got its name.

Since when moving along the chamber, the fluid flow swirls, before entering the elbow, it enters the guide apparatus. Its function is to quench the turbulence and direct the jet into the pressure pipe.

There are two types of axial pumps: the blades on the sleeve can be rotary or rigidly fixed, which allows you to change their technical characteristics. Compared to centrifugal pumps, axial units have a higher efficiency. By this principle, mainly industrial equipment is created, and one of these options you see in the photo above.

Diagonal

A distinctive feature of these pumps is the fact that the fluid flow does not move along the chamber radially, and not along the shaft, but deviating from the pump axis at a certain angle. This feature allows you to use both centrifugal and lifting forces, so we can safely say that the diagonal pump combines the characteristics of the two previous options.

The liquid flow can be diverted in a diagonal pump, it can be done either in a spiral or in a tubular chamber - it depends on the modification.

According to operational characteristics, it occupies an intermediate position between the centrifugal and axial design. Therefore, both domestic pumps and units for production circulating systems can be diagonal.

Functions of the pump in the heating system

The circulation pump ensures uniform distribution of the coolant throughout the heating system, and most importantly, prevents the formation of air jams that lead to a decrease in its temperature.

So:

- Usually, two identical pumps are installed in the heating system, which operate alternately. That is, one pumps water, and the second is in reserve at this time.

But there is also a more convenient option: a twin pump. Doing it yourself is much easier to implement in the heating system. Such models are now offered by almost all the leading manufacturers of this equipment.

- There are modifications of dual circulation pumps that are able to work in different modes. For example: each unit can function independently of the other; or once a day, the operating mode automatically switches from one block to another. Standby mode is also possible: in this case, if one pump fails, the second is switched on automatically, within a few seconds.

- In general, in autonomous heating systems, mainly centrifugal pumps are used. They are divided into two types due to the fact that the pump rotor can be immersed in water, or not interact with it at all. Hence the names: “with a wet rotor”, and “with a dry rotor”. Naturally, they have constructive differences.

Wet rotor

In this case, the rotor along with the blades is immersed in water, which cools the engine. It is separated from the stator by a steel sealed capsule.

Wet rotor pumps can only pump pure water or a mixture of water with glycol used in heating systems:

- They practically do not require maintenance, and therefore, do-it-yourself circulation usually comes down to troubleshooting, most often related to problems in the system itself - we will talk about them later. Models with a wet rotor are convenient in that they have a function for rotating its speed.

Even if you made a mistake with the specifications when buying, there is always the opportunity to adjust the pump. This function allows you to use this equipment not only in two-pipe radiator heating circuits, but also in underfloor heating systems.

The silent operation of wet rotor pumps also contributes to this.

Dry rotor

In these models, the working part of the rotor is separated from the engine by stainless steel o-rings. When the mechanism starts, a thin film of water is created between the rotating rings, which, being under pressure, makes the connection absolutely tight.

So:

- Despite the fact that such pumps are quite noisy in operation, they have a higher efficiency. Therefore, almost all industrial models have just such a design. They are installed on shock-absorbing pillows, in separate, well-insulated rooms.

- Dry rotor pump housings can be block, horizontal and vertical. It depends on where exactly the suction and discharge pipe is located. In any case, the liquid must be filled in the housing, which is necessary for lubrication.

Causes of System Failures

In order to not have to repair the pump, you need to periodically monitor the process of its operation:

- First of all, you should make sure that there is no vibration, excessive noise and overheating of the motor.

- From time to time, the threaded portion of the screws holding the flanges must be lubricated.

- The pump casing must be earthed, but this does not eliminate the need to regularly check the quality of cable terminal connections.

- It is also necessary to check the pump insertion points into the pipeline: if there is a leak, the seals are replaced and the threaded connections are tightened.

List of problems and solutions

Home heating systems use mainly wet rotor models, and they have one advantage - they are equipped with control modules.

These are additional devices, a kind of automation that allows you to control the pump:

- With it, you can program the operating time for a day or a week, in the modes of comfortable or reduced temperature. You can configure the system so that the pump will start according to the thermostat, that is, when the room temperature cools to a certain temperature.

- Such a pump control system is incredibly convenient. And in general, their design is so reliable that most often, the repair of circulation pumps is reduced only to replacing a failed module.

But still, sometimes problems arise, and we list them:

| What is the malfunction | Possible causes of its occurrence | Your actions |

| When you turn on the pump "comes to life", but its shaft, however, does not rotate. | a) Most often this happens after a long period of inactivity - the shaft is oxidized. b) The impeller is blocked as a result of the ingress of a solid particle. c) Power outages. | 1. Turn off the power of the pump, and drain the water from the pipeline. 2. Unscrew the screws on the housing, and remove the motor together with the rotor and impeller. 3. Check if, for example, the scale got from the pipeline. If so, remove the dirt. In order to avoid repeated blockages, it is better to install a fine filter in front of the pump. 4. Check the mains voltage, the presence of phases, and the correct connection of the terminals. 5. Turn the wheel manually or with a screwdriver inserted with a notch specially designed for this purpose. |

| The pump does not turn on at all and does not show signs of life. | a) The cause may be too low a voltage or a complete lack of power. b) The fuse may have blown. | 1.Check for current, voltage and all connections. 2. Replace the fuse. |

| After starting the pump, after working for a while, it stops. | The formation of calcareous deposits between the rotor and the stator. | Dismantle the engine and descale the metal liner. |

| When turned on, the pump emits sharp sounds or vibrates. | a) Air has entered the flow part of the working chamber; b) The phenomenon of cavitation (vapor formation), which is always accompanied by vibration; c) The bearing has worn out. | 1.If such problems occur, bleed air. And better, install an automatic plunger at the top of the pump piping.

3. Bearing replacement. |

| Pump flow and pressure do not match manufacturer specifications | a) The impeller rotates in the opposite direction. b) The increased hydraulic resistance on the circulation ring. | 1. Incorrectly connected phases: check, fix.

3. Sometimes it’s just enough to clean the filter. |

| Automatic protection of the pump motor is triggered. | The problem is only with electricity. | Check the correct connection of the phases, and their resistance to ground, as well as the integrity of the fuse. |

The causes of problems in the heating system may be such factors:

- Errors when installing the pump, for example: deviation of its shaft from the horizontal. In this case, air can enter the pump housing, and this will damage it.

- Incorrect cable routing and connection.

- Insufficient fluid in the system.

- Lack of fluid in the cooking chamber.

- Pump operation at zero flow, or such a mode of operation when the flow is less than the actual flow of water.

- In the heating system, where a pump with a wet rotor is installed, it is necessary to ensure that the temperature of the coolant does not exceed +65 degrees, since salt boils when water boils. For pumps with a dry rotor, this does not matter.

And yet: during a long period of inactivity, for example, in the summer season, when the heating does not turn on, the pump must be turned on at least once every three to four weeks, for twenty minutes. Otherwise, its shaft may oxidize and block spontaneously, as was mentioned in the table of possible malfunctions.

The circulation pump is a frequent element of the individual heating system in their own homes. This device allows you to efficiently drive the coolant in a closed loop, thereby ensuring a constant temperature in all areas of the heating system and the complete absence of air jams in the same place. But even with the most reliable equipment, troubles sometimes occur in the form of malfunctions. And therefore, sometimes it is necessary to repair the circulation pump in order to return the home heating system to its original efficiency.

It is noteworthy that, despite the diversity of the model range of circulation pumps, the principle of their operation and maintenance are the same for all devices. Therefore, in this material we will consider options in which you can avoid the services of professional specialists in a service center and repair the circulation pump with your own hands.

How is the unit arranged?

In order to understand the principle of repairing pumping equipment, it is necessary to thoroughly understand its structure. Such knowledge will help to quickly detect malfunctions in the mechanism and eliminate them.

So, the device of a standard circulation pump for heating systems is as follows:

- A large horizontally elongated steel casing in which all the working units of the system are located. In addition to steel, a durable aluminum alloy or stainless steel can be used for the unit body.

- The housing houses a powerful electric motor and rotor.

- Here, on the rotor, the impeller is fixed with blades that are curved in the opposite direction from the movement of the wheel. Typically, this pump element is made from durable polymers.

Important: the impeller in the pump can be located both horizontally and vertically depending on the model. In this case, it is necessary to install the unit so that the impeller is parallel to the pipeline.

How does the circulation mechanism work?

When the pump is turned on, water in the heating system (in a closed circuit) is drawn into the inlet under the influence of rotation of the wheel with blades. Due to the action of centrifugal force, water entering the chamber is pressed against the walls of the working chamber and pushed out (into the outlet). Following this, the pressure in the chamber drops, which contributes to a new injection of water into the pump reservoir.

Thus, during the continuous cycle of the pump, the heating system can be in a constant set temperature, which significantly reduces the cost of fuel or electric energy for heating water.

Important: the circulation pump is able to process water up to 95 degrees Celsius, which makes its use even more justified in individual heating systems. But it is not recommended to constantly drive water of this temperature through pipes. This will negatively affect the durability of the equipment.

Types of circulation pumps

To conduct high-quality repair of the circulation pump, it will be useful to learn about the types of such equipment. So, there are two types of devices for working with water in a closed loop:

- Wet rotor mechanisms;

- Dry rotor pumps.

In the first case, the units are designed for constant contact of the rotor with the pumped liquid. As a result of this design, natural cooling and lubrication of all pump elements rubbing against each other occurs. Installation of the pump with a wet rotor should only be carried out in a horizontal position so that the rotor always comes into contact with water. A device of this type has a low noise level at work and a more affordable price. In addition, wet rotor pumps are easier to maintain and maintain.

Dry rotor units. Here the rotor is located in a separate dry chamber. In this case, the torque is transmitted to the rotor thanks to a special coupling. It is worth noting that circulation pumps with a dry rotor have great power and performance, in contrast to their "wet" counterparts. But at the same time they are distinguished by a more complex device, which means they require more professionalism in identifying the causes of the malfunction and conducting subsequent repairs.

Important: dry rotor pumps, unlike water supply units, can run dry. Only the load on the drive will be colossal, which will lead to rapid wear of the equipment.

It is worth noting that important pointthat all circulation units by type of housing design can be divided into monoblock devices and cantilever. The first have a single block body in which all the working nodes are located. The second consists of two blocks, each of which is designed for specific work units.

How to protect the pump from malfunction?

In order to be safe and avoid damage to rather expensive pumping equipment, it is recommended to adhere to some basic rules for the operation of equipment of this type:

- Do not allow the pump to turn on without a coolant in a closed loop. That is, if there is no water in the pipes of the heating system, then you should not “torment” the pump. So you will provoke a quick breakdown of the equipment.

- It is advisable to always maintain the required volume of coolant in the pipes. Otherwise, the pump will work for wear, both in case of excess water volume, and in case of shortage. For example, if the pump can distill the amount of water from 5 to 105 liters, then the need to work with volumes from 3 to 103 liters will already greatly deteriorate the operating units of the unit, which will lead to its failure.

- In the event of prolonged shutdown of the pump (during the non-season of heating), it is necessary to run the unit in operating position for at least 15 minutes once every month. This will avoid oxidation of all movable elements of the pump unit.

- Try not to exceed the temperature of the coolant above 65 degrees Celsius. A higher rate will adversely affect the working and movable parts of the structure.

- In this case, check the pump housing for leaks more often. If at least the slightest leak is observed somewhere, you should immediately identify the malfunction and conduct maintenance pumps.

Prevention Actions

It is also recommended to carry out preventive maintenance of the unit to protect pumping equipment from a sudden failure, which will include such actions:

- Regular external inspection of the pump casing and its thorough listening in the operating mode. So you will be able to check the efficiency of the pump and the tightness of the housing.

- Ensure that all external pump fasteners are properly lubricated. This will make it easier to disassemble the pump if repairs are necessary.

- It is also worth observing some rules when installing the pump unit for the first time. This will help to avoid repair work in the future:

- So, when connecting the pump to the heating network for the first time, it is worth turning on the unit only if there is water in the system. Moreover, its actual volume must correspond to that indicated in the technical passport.

- It is also worth checking here and the coolant pressure in a closed loop. It must also comply with what is stated in technical specifications unit.

- In addition, ensure that grounding when connecting the pump is between the pump and the terminals. Here, in the terminal box, check the absence of moisture and the reliability of the fixation of all wires.

- A running pump should not produce even minimal leaks. Particularly noteworthy are the junctions of the inlet and outlet pipes of the heating system with the pump casing.

Possible breakdowns and solutions

So, if, nevertheless, a trouble happened with your circulation pump and it refuses to work, then we will try to repair the unit with our own hands.

Important: but if you are not confident in your abilities or do not have the appropriate tool at hand, it is best to contact a specialized center.

If the pump makes a hum but the impeller does not rotate

The reasons may be the following points:

- The presence of a foreign object in the area of \u200b\u200bthe impeller;

- The rotor shaft is oxidized due to prolonged shutdown of the unit;

- Violation of the power supply to the terminals of the mechanism.

In the first case, you need to carefully remove the pump from the heating system and untwist the housing in the area of \u200b\u200bthe impeller. If a foreign object is detected, remove it and turn the shaft by hand. When assembling the pump in the reverse order, you must install a reliable filter on the nozzle.

If de oxidation takes place, then it is cleaned well, all movable elements of the working unit are lubricated, and the pump is assembled in the reverse order.

If there is a problem in the quality of the power supply, then you have to check the voltage with a tester. First, in all areas of the cable and if a break or malfunction is detected, completely replace the latter. Then, if the cable is OK, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows a lower voltage, then the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, fix the problem.

By the way, it is recommended to protect the pump from changes in the network by installing a reliable stabilizer. Such a move will also protect the pump from fuse burning, which fails as a result of constant pressure drops in the network.

If the pump turns on but then stops

Reasons may include:

- The presence of scale between the moving elements of the unit;

- Incorrect pump connection in the terminal area.

In the first case, you will have to disassemble the pump and check it for scale. In case of detection, limescale is removed and all joints between the rotor and stator are lubricated.

If there is no scale, then check the fuse on the unit. Remove it and thoroughly clean all clamps. Here it is worth checking the correct connection of all the wires in the terminal box in phases.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in a closed loop. It is necessary to let out all the air masses from the pipes, and install a special unit in the upper part of the pipeline to prevent the formation of air jams.

Another reason could be impeller bearing wear. In this case, it is necessary to disassemble the housing of the unit, check the bearing and, if necessary, replace it.

If the pump is noisy and vibrates

Most likely, this is due to insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the inlet area of \u200b\u200bthe pump.

If the pressure is still small

Here it is worth checking the direction of rotation of the working unit in the pump casing. If the wheel does not spin correctly, then there was probably a mistake in connecting the device to the terminals in phases in the case of using a three-phase network.

Another reason for the decrease in pressure may be too high viscosity of the coolant. Here the impeller experiences a lot of resistance and does not cope with the tasks. You will have to check the condition of the strainer and clean it if necessary. It will also be useful to check the cross-section of the inlet and outlet pipes and, if necessary, set the correct pump operation parameters.

Exploitation

If all de have to repair the pump, then prepare a bypass. This is a section of the bypass pipe that will close the circuit for the duration of the repair work.

Important: repairing the pump by weight by disconnecting it from one of the nozzles is not recommended. The heating pipe may break, especially if it is plastic.

If you have to open the pump housing, and the bolts turn out to be intractable, then you can use a special tool called “liquid keys”. It must be applied to the fasteners and after a while the bolt will succumb to the impact of a screwdriver.

And most important: do not open the pump yourself if its warranty period has not yet expired. It is better to contact a service center in this case. In addition, in difficult cases, it may be cheaper to buy a new pump than to find accessories or parts on it.