Circulation pump for heating device. Types, characteristics and installation features of circulation pumps

Circulation pumps used in heating systems and hot water supply (hot water). The principle of operation is based on the forced circulation of the fluid through the enclosed space of the pipeline.

Such pumps are used in heating systems of multi-storey buildings and country cottages. Due to the use of circulation pumps, the rooms warm up faster and more evenly than when using the natural circulation of the coolant, where hot water is supplied through a vertical pipe (riser) due to the method of natural convection.

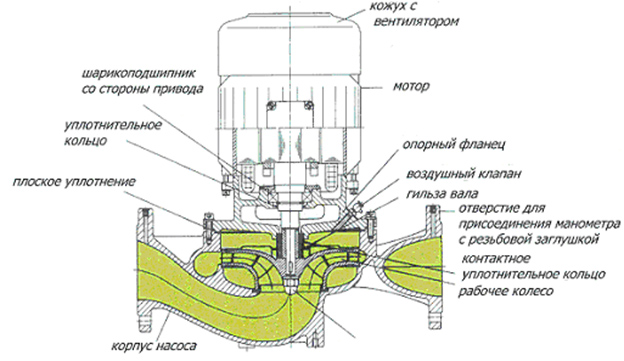

1 Description, device, principle of operation of the circulation pump

According to the device, the circulation pump, in fact, is similar to a drainage installation. In the case from stainless. steel, cast iron or aluminum (sometimes - bronze, brass) built-in rotor made of ceramic or steel. The rotor shaft is equipped with a wheel with impeller blades. A wheel with blades is most often made of technopolymer.

The action of such a device is due to the principle of centrifugal force, which is formed during the operation of the impeller. The movement of the coolant is carried out by capturing it on one side and forcing it into the pipeline on the other. Vacuum is generated in the suction pipe during the rotation of the impeller. Vacuum is responsible for the continuous process of circulating and supplying water to the suction pipe.

Water in such a mechanism can circulate at a speed of 2 m / s in domestic applications (to avoid vibration and noise and pipes) and up to 8 m / s in industry. The pumps are powered by electrical energy, which is their advantage. After all, such a device, used in the industrial field, consumes no more than 0.3 kW, in the household - up to 85W.

A heating system using circulation pumps is able to efficiently heat rooms with any configuration of piping, with pipes of small diameter, including those built into the floor or walls.

The advantages of using this type of pump include:

- fast heating of the room;

- creation of a separate temperature regime in each room by means of a thermal relay;

- installation of the boiler anywhere;

- the ability to adjust the rotor speed, which reduces energy costs;

- minimum number of air jams.

1.1 Types of circulation pumps

Two types of circulation pumps are produced: “wet” and “dry” (with wet and dry rotor).

For the “wet” type, it is characteristic that the rotor is located directly in the fluid that is being pumped. The electric motor is located in a sealed part, where water does not get. The principle of operation of this mechanism is as follows: a rotating rotor accelerates the movement of water. The fluid in which the rotor is located is a cooler and lubricant for the mechanism.

Wet rotor mechanisms are used in heating systems with a relatively small piping length.

Advantages of the “wet” type of pumps:

- low noise level;

- simplicity in changing settings;

- stepless change of rotor speed;

- long period of service;

- lack of need for maintenance.

The main disadvantage of this type of device is the low level of efficiency (not exceeding 50%). The reason for the low productivity is that it will be practically impossible to seal the sleeve that separates the stator from the pumped liquid with an increase in the diameter of the rotor.

In a “dry” type pump, the rotor does not come into contact with the coolant. Its working part is isolated from the engine by means of o-rings, which are made of coal sinter, ceramic or stainless steel.

Such pumps are more efficient. In the process, the O-rings self-adjust and rub against each other. The period of their service is not less than 3 years. The efficiency is about 80%. But at the same time, running pumps with a dry rotor make a lot of noise, which is why they need to be installed in separate rooms with sound insulation. You also need to consider the environment of the room in which such units are located. In the process, they create air turbulence, dust can rise up and penetrate into the system, which leads to damage to the surface of the seal rings.

2 Popular Manufacturers

Due to the great demand for these products, dozens, if not hundreds of enterprises around the world produce different types of circulation pumps. Therefore, I propose to review the products of some foreign manufacturers - manufacturers, as well as pumps manufactured in Russia.

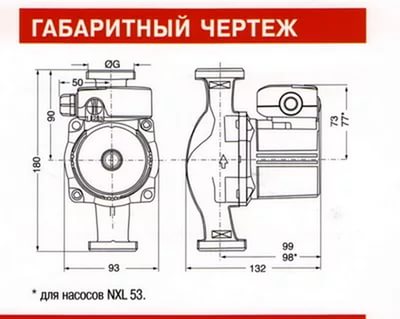

2.1 Salmson NXL

The French company Salmson is part of the industrial group WILO AG. Today, under the Salmson brand, a wide range of pumping products is produced, which has such characteristics as reliability, high quality, compliance with European standards.

Salmson circulation pulsers are used in central airs, water supply, heating, ventilation. Their distinguishing feature is that the rotor is practically not subject to contamination, since the water entering it passes through the filter.

In addition, the products of this series are characterized by the versatility of the model range, low noise, high quality and low cost. The pumps are equipped with a bronze casing, which makes it possible to use them for drinking water systems.

2.2 Wester WCP 25-40 G

Household surface circulation pump with nuts. Used for heating, air conditioning and underfloor heating. It can pump hot water, chemically non-aggressive fluids or fluids with a viscosity of not more than 2 sq.mm / s.

It has a “wet” rotor, manual three-stage switching of the number of revolutions.

The body is made of cast iron, the impeller is polymer.

Specifications:

- power - 93W;

- max head - 6m;

- throughput - 2.7 m3 / h;

- max temperature of the passed liquid - 110 ° C;

- max ambient temperature - 40 ° C;

- accession - 1 inch;

- max working pressure - 10 bar.

2.3 Vaillant 160928

The Vaillant circulation pump is used for operation of gas boilers ATMOmax and TURBOmax, as well as in heating and domestic hot water systems.

It supplies the coolant to the heating system or to the secondary heat exchanger. In the latter, heating of cold water occurs.

Vaillant has first and second degrees of rotation speed with the ability to manually switch. Manufacturers recommend keeping the pump in the second stage, since there will be greater thermal power of the water supply and less time for heating the water. The unit is switched to the first stage when it is necessary to reduce the noise level during its operation.

2.4 Vortex BWZ 152 ½

This German-made equipment is suitable for heating systems and water supply systems. The Vortex circulation pump can pump hot water, chemically non-aggressive liquids or liquids with a viscosity of not more than 2 sq. Mm / s, ethylene glycol with a concentration of not more than 40%.

Features:

- “Wet” rotor;

- three-position speed control;

- union nuts are included;

- case - cast iron;

- impeller - polymer;

- motor case - aluminum;

- silent process of work;

- small dimensions.

Index Z indicates the presence of a daily mechanical timer with a time step of 15 minutes.

Power - 0, 025 kW, power - 230V, 50 Hz.

2.5 Lowara TLCSOL

The Lowara TLCSOL circulation pump with a wet rotor is used in solar systems (systems with solar collectors).

Pumps are characterized by silent operation, as well as simple installation, which makes it possible to install them in any room. The kit additionally includes 2 union nuts and a heat-insulating cover.

Characteristics of Lowara TLCSOL circulation pulsers:

- country of origin - Italy;

- pumped liquid - water;

- voltage - 230V 50 Hz;

- max water temperature - 110 ° C;

- min water temperature - -10 ° C;

- case - cast iron;

- impeller - composite material;

- bearings - ceramics.

2.6 ATSML 1000

Russian-made single-stage centrifugal circulation pumps ATSML 1000 are used in heating, water supply, fire fighting, irrigation and chemical production systems.

They are characterized by low noise and high efficiency. There are various modifications to shaft seals. Transported liquid - pure water; liquids that are similar in characteristics to water; slightly aggressive and aggressive fluids.

Specifications:

3 How to choose a circulation pump?

If you need a circulation pump, when choosing it, you should pay attention to the main characteristics: performance, pressure, coolant temperature, noise level, and also how much electricity it consumes.

Under the performance of the circulation pump understand the amount of distilled liquid. It is recommended that the pump pump over a volume of water equal to three volumes of the heating system per hour. It is recommended to choose a unit with a capacity of 10-20% in stock. Then it will not wear out for a long time and the premises will warm up enough in the winter.

Also, the pump must provide sufficient pressure to overcome the resistance of the pipeline, raise the fluid to the desired height, overcome all the bends of the heating system.

It is also necessary to clarify the temperature of the pumped liquid and correlate it with similar characteristics of the unit, as well as the type of coolant - water or antifreeze.

When considering the issue of energy consumption, it should be borne in mind that some of the most modern pumps consume less energy than a conventional light bulb. In addition, the automatic regulation of heating devices will help you save energy. In this case, the circulation pump will operate intermittently. A special sensor will show when the coolant temperature has dropped below the set line and will start the pump.

The life of the pump will depend on how correctly you determine all the characteristics of the pump for your heating system.

3.1 Circulation pump for heating: device, operation, installation (video)

The circulation pump is a key figure in modern heating systems with forced circulation of the coolant. Its use eliminates the need to install the boiler at the lowest point of the room and makes it possible to use pipes of small diameter with an arbitrary arrangement of the main. In addition, the introduction of a circulation pump into the circuit increases the heating performance and reduces energy costs. The service life of the unit directly depends on the correct installation and the compliance of technical specifications with the hydraulic parameters of the heating system. We will understand the intricacies of pump designs and the nuances that you need to pay attention to when choosing a device.

![]()

Circulation pumps for heating systems

The pump for heating systems consists of a cast-type housing, a ceramic or steel rotor with a plastic or alloy impeller (impeller), a stator installed in the casing, and a terminal box with an adjustment device.

When the electric motor rotates, the impeller discards the coolant to the outer edge of the cochlea made in the housing. Further movement and injection of the working fluid occurs due to centrifugal force. At the same time, a vacuum occurs at the inlet of the pump, which contributes to the absorption of a new portion of the coolant.

The design of the circulation pump is typical for centrifugal units, but at the same time it has many interesting structural solutions

Design of pumps for heating systems

Depending on the design, all the pumping units of the heating systems are divided into two types:

- dry circulating pumps;

- wet rotor pumps.

Both types of devices are quite effective in heating pipelines and have both advantages and disadvantages.

Dry type pumps

In devices with a dry rotor, the electric motor is moved outside the pump casing

In such units, the rotor does not come into contact with the working fluid, since all elements of the electric motor are separated from the working chamber of the device by a special type sealing system. It consists of polished, carefully adjusted metal rings to each other. To eliminate friction, between the elements of the seal is constantly a thin film of liquid, which plays the role of a lubricant. It is she who prevents damage to the seal rings.

Depending on the location of individual structural elements, dry pumps of heating systems can be divided into three types:

- console-type pumps;

- vertical centrifugal pumps;

- block pumps.

The suction nozzle of the cantilever circulation pumps is located on the outer edge of the cochlea, while the discharge part is carried out in the opposite direction. A feature of units of the second type is the location of the electric motor in a vertical plane, which can significantly improve the performance of devices.

Dry rotor circulation pump device

Dry rotor pumps have numerous advantages:

- long term of operation;

- high performance;

- Efficiency is close to 80%;

- the ability to work with a coolant leak;

- high maintainability;

- relatively low cost;

- reliability;

- possibility of installation in any position.

However, the increased noise level of units of this type does not allow them to be installed in residential premises. Cons also include cleanliness requirements and the need for periodic maintenance and lubrication of the rolling seal.

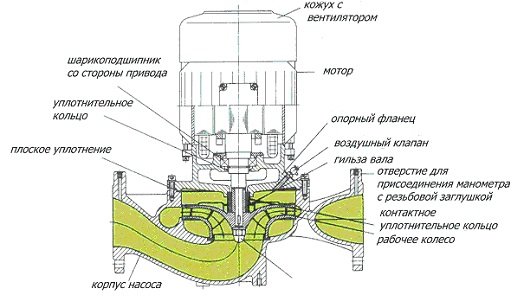

Wet Rotor Circulation Pumps

The advantages of wet rotor circulation pumps have opened up broad prospects for their use in autonomous heating systems

The rotor and impeller of this type of pumps are located in the pumped coolant, which perfectly copes not only with its main function, but also with the cooling of the motor parts. The stator of the pump electric motor is separated from the rotor by a sealed glass made of non-magnetic steel or carbon fiber. Units of the "wet" type are designed to work in systems with stable, rarely changing fluid flow. The presence of the control unit allows you to vary the number of connected windings, and accordingly, change the pump performance. The choice of the optimal operating mode positively affects the efficiency of the unit.

The advantages of units of the "wet" type include:

- low noise level;

- no need for lubrication;

- effective way of cooling;

- ease of maintenance and installation;

- relatively low price of the unit and spare parts;

- long term of operation.

Pumps with a wet rotor are not without drawbacks in the form of low efficiency (a little more than 30%), the inability of the unit to work without a coolant and the requirements for horizontal orientation of the rotor shaft during operation.

Design features by connection method

The flange connection is most often used in high power pump models.

In utility and industrial pipelines, dry rotor circulation pumps are most often used as more productive and powerful devices. Their connection is carried out mainly by flange connection, and for installation, both a common support frame and a specially equipped foundation can be used. At the same time, manufacturers also produce devices designed for installation in autonomous heating systems. As a rule, they all have increased power and performance, and their installation does not require special fastening.

Mounting elements must be included in the scope of delivery of pumps with a coupling type of connection

Couplings for circulation pumps are typical for low-power wet-type units with direct flow of coolant, which can be built directly into the pipeline. Such devices are represented by a wide range of domestic centrifugal pumps, while powerful industrial units with a flange connection require additional fastening of the pipeline using the console and foundation.

Criterias of choice

The effective operation of the heating system is directly related to the performance of the circulation pump and the pressure on its outlet pipe.

At low power of the unit, an insufficient amount of coolant will be pumped through the system, which will not make it possible to reach the required temperature.

In addition, when used in everyday life, important factors affecting the choice are considered the noise level (which depends on speed) and the efficiency of the electric motor of the unit. The correct selection of the heating system pump requires thermal and hydraulic calculations, based on which the optimal technical characteristics are determined.

Selection and installation of circulation pumps for heating systems (video)

Required performance

Before proceeding to determine the performance (flow rate, volumetric flow) of the circulation pump, the amount of heat required to heat the room in the coldest time of the year is calculated. To calculate this parameter, there are special formulas that include both the physical parameters of the room and possible heat losses. We suggest using a simplified calculation method applicable to the middle band of our country. It lies in the fact that the required amount of heat for heating 1 square meter of the premises is 100 watts. Therefore, to determine the required amount of thermal energy, the total area of \u200b\u200bthe premises in the house or apartment should be multiplied by 100. For thermally insulated buildings, this parameter is reduced by 25 - 30%.

P is the required thermal power, kW;

Tf - temperature on the supply side, ºС;

Tr is the temperature in the return line, ºС.

For example, for a house with a total area of \u200b\u200b80 sq.m at a coolant temperature at the outlet of the boiler of 70 ºС and in a return pipe of 50 ºС, the flow rate will be at least Q \u003d 8 × 0.86 / (70-50) \u003d 0.34m3 / h.

Calculation of the required pressure

The next step when choosing a pump is to calculate the supply pressure of the coolant. From this characteristic depends on how easily the unit can overcome the hydraulic resistance of the fluid in the pipes of the heating system. The pressure value is calculated by the formula:

H \u003d 1.3 × (S1 × L1 + S2 × L2 + Z1 + Z2 + ... Zx) / 10000, here:

S1, S2 - pressure loss in the pressure and return lines, Pa / m;

L1, L2 - respectively, the length of the feed and return branches, m;

Zx - individual resistance of pipeline sections, Pa.

Table of hydraulic resistance values \u200b\u200bfor various pipeline parameters

The values \u200b\u200bfor the calculations can be taken from the technical passports for equipment and structural elements of heating systems or from special tables. For simplified calculation, you can use the following values:

- resistance of straight pipe sections - from 100 to 150 Pa / m;

- losses on fittings make up to 30% of resistance on straight sections of pipelines;

- resistance on thermostatic valves adds up to 70% of the calculated value.

Pressure loss at the nodal points of heating systems

Having received the values \u200b\u200bof the volumetric flow and pressure, the required model of the circulation pump is selected from the catalog.

Engine power

An important characteristic of a centrifugal pump is power, since it is this parameter that affects how much electricity its electric motor will consume. Modern devices are equipped with a system of step adjustment, which helps to choose the most optimal mode of operation.

Consumption of domestic circulation pumps is minimized and comparable to a small light bulb.

In addition, manufacturers are constantly working to improve the energy efficiency of the units. For this purpose, a unified classification by this parameter has been introduced. For example, the consumption of Class A appliances is not more than 6 W, which will require a little more than 90 kW / h of electricity per year. The power of the circulation pump, as well as the power of the consumed current, is indicated in the technical passport for the product and is duplicated in a plate located on its body.

Noise level

The specifics of using modern circulation pumps in domestic conditions forces manufacturers to resort to non-standard solutions to reduce the sound pressure level. So, to reduce cavitation that occurs during operation of the unit, blades and channels of optimized shape are used, and pump housings are massive structural elements. In addition, the rotating parts are placed in a liquid, which also contributes to silent operation. Most often, the noise of the unit does not exceed 45 dB when operating at the highest speeds. If the regulator is installed at the minimum level, then it is almost impossible to hear the sound of rotating elements.

The complexity of installation and operation

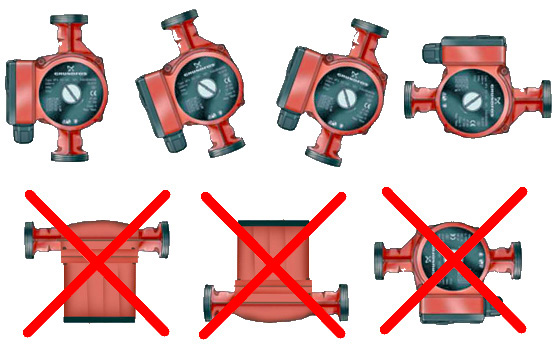

For long-term and reliable operation of the centrifugal pump of the heating system, it is important to install it correctly. Previously produced models were recommended to be mounted on reverse heating branches due to the lowered coolant temperature, and, accordingly, better cooling of the device’s electric motor. Modern units are made of high-strength, heat-resistant materials, so such restrictions are currently removed. However, manufacturers require the pump to be installed only in positions in which the rotor shaft will occupy a horizontal orientation in space. An important factor affecting the service life of the product is the lack of air in the pipes of the heating system. Therefore, the installation of expansion tanks and Mayevsky cranes is mandatory.

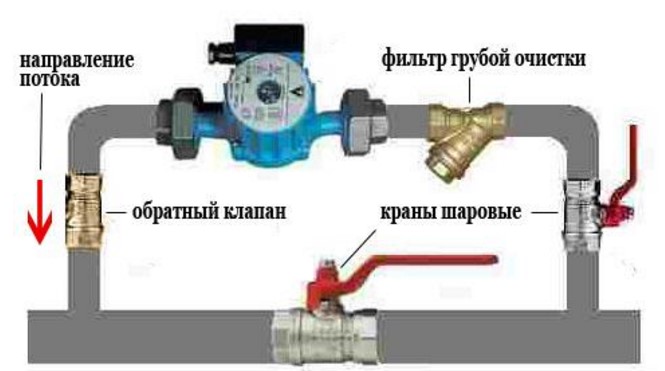

When installing, it is necessary to provide a bypass line necessary for the operation of gravity heating systems when the pump fails. At the same time, shut-off ball valves are mounted on both sides of the pump, and a coarse filter and a check valve are installed on the side of the boiler. Such a scheme increases the service life of the unit and increases the reliability of its operation.

During operation, the pump does not require maintenance. The only thing that may be required when turning on the device is to turn the rotor to facilitate its starting and to remove air from the working chamber. To do this, there is a special plug on the device body, and a groove for a screwdriver is made on the rotor shaft.

Starting the pump and removing air from its working chamber (video)

Thanks to the agreement of the manufacturers of centrifugal pumps, their marking is unified and has the following features:

- the first numbers after the brand of the unit indicate the connecting diameter of its nozzles;

- the next number characterizes the pressure.

For example, the designation WILO 25-60 indicates that the unit manufactured by WILO is designed to be connected to bends with a diameter of 25 mm or 1 ″, and its head is 6 m or 0.6 atm. Information about the model of the pump contains a plate located on the device. In addition, it includes current consumption data for various operating modes.

Marking of circulation pumps

Manufacturers and prices

Circulating pumps of many manufacturers are on the market. Units of the German company Grundfos possess excellent quality and technical characteristics. The cost of low-power devices from their model range starts at 6,600 rubles for the UPS 25-40 model and exceeds 19,000 rubles for the UPS 32-80 model.

Products of another German brand WILO possess an excellent price / quality ratio. So, for a product with parameters 25-20 you will have to pay from 5990 rubles, while the cost of a powerful pump with a pressure of 80 m is almost 11 thousand rubles. As you can see, compared to Grundfos, the difference is significant.

More budget solutions can be found in the line of models of the Italian company DAB and Pedrollo, the price of which is reduced by about 25% compared with German counterparts. From inexpensive products, we can distinguish products under the Chinese brand SPRUT. The LRS 25-40 pump can be bought for only 1800 rubles, while for the most powerful LRS 32-120 you will have to give no more than 9 thousand rubles. The only problem remains the build quality and components from China.

The choice of a centrifugal pump determines how reliable and efficient the heating will work. Therefore, we need an accurate calculation of all parameters, taking into account the specific features of the piping layout. Correct installation of the unit affects the service life and performance, therefore, during installation, the recommendations of the equipment manufacturer must be strictly observed. Only in this case the pump will be able to work for a long time, delivering comfortable heat to every corner of your home.

The modern heating circulation pump is a reliable device that does not require maintenance.

In the event of a serious breakdown, the repair of heating pumps is trusted by professionals. Minor errors in the work are repaired independently.

1 Operating Rules

To prevent breakdowns, observe the operating rules:

- it is forbidden to operate the pump for heating a house in the absence of water in the system;

- do not use the unit at zero feed;

- during operation, the feed limits are observed;

- to prevent oxidation during downtime, the unit must be turned on for fifteen minutes;

- the temperature of the working fluid does not exceed sixty-five degrees Celsius;

- lack of leaks at the joints of pipes;

- lack of heating of the unit;

- do-it-yourself pump installation with horizontal shaft placement.

Subject to the rules, the unit is able to last ten years.

2 Breakdowns and remedies

Depending on the problem, the cause of the breakdown and its elimination are determined:

- the circulation pulser does not turn on and does not make noise. The reason is a burned-out winding or a fuse has failed. The fuse or winding changes;

- when the unit is turned on, a buzz is heard, but the shaft does not rotate. Why is the unit humming but not working? Most likely, during prolonged downtime, shaft oxidation occurred. If the device is blocked, it is disconnected from the network. The screws securing the engine and housing are loosened. The motor is removed and the shaft rotates. For low-power units, the shaft is unlocked with a screwdriver;

- the pump shuts off after turning it on without starting to work. The reason is scale between the stator and the rotor. After dismantling the engine, salt deposits are cleaned;

- during operation, the apparatus begins to warm up. Why is the motor warming up? There are several reasons for heating. Incorrect installation, poorly lubricated bearing, low mains voltage, clogged system. To eliminate the voltage problem, an uninterruptible heater for the heating pump (UPS) is installed. For continuous supply of power, protection against power surges, use a UPS. In the absence of electricity in the network, the UPS will ensure the operation of the unit for fifteen minutes (used as a power source). The UPS will protect the pump motor in the event of a surge, sudden drop, or fluctuation in the line voltage. By connecting the UPS, the heating system will be protected from power surges. Mains power will be safe;

- power problem. The correspondence of the actual voltage in the network with the one specified in the characteristic is checked;

- the impeller is locked. To troubleshoot, you need to know how to disassemble the device. To eliminate the breakdown, the wheel is dismantled and a foreign object is removed. To prevent a repeat lock, a filter is installed at the pump inlet;

- when turned on, the pump may hum. The reason is the accumulated air. To fix the problem, bleed air from the system. Automatic air vents will constantly bleed air. An air vent is needed to bleed air during operation and start-up of the system;

- during operation, the unit vibrates. The reason is bearing wear. Bearing replacement required. The second reason is a clogged filter. Flushing and cleaning the filter is required;

- after inclusion protection of the electric motor works. The reason is the electrics of the engine. It is necessary to contact a specialist;

- water head is lower than prescribed technical specifications. When installing the device, they made a mistake. It is found in three-phase types of equipment.

2.1 Repair of the heating pump with your own hands (video)

2.2 Breakdown prevention

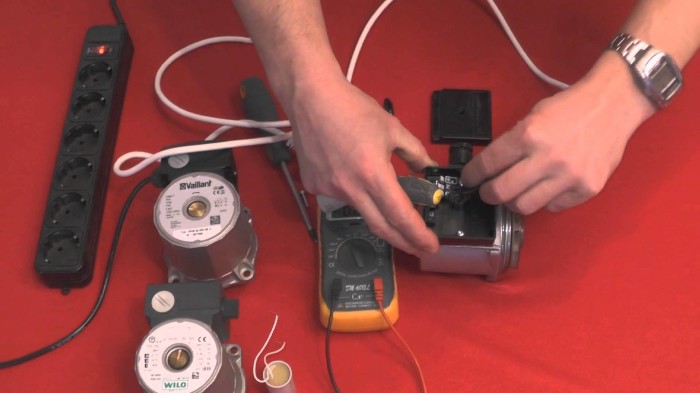

To prevent damage, it is necessary to check the health of the heating pump with your own hands. Before starting the heating season, the unit is checked for damage.

Prevention measures:

- Check for grease. When the nozzles dry, they are lubricated.

- Check if the device is connected to the network correctly. When planning the heating system, a pump is located in front of the boiler. This measure will reduce air congestion to zero.

- Equipment with the help of a tester is checked for the correct connection to the network.

- Cleaning the filter from dirt.

- Before starting heating, test the equipment. To pressure test the heating system, water or air is supplied to the system. For crimping, a hydraulic or pneumatic pump is used.

2.3 the effect of the crimping process on the discharge mechanism

The crimping process provides quality service for the entire heating system.

In order for the entire system to work without leaks and turn on without problems, carry out this procedure. The procedure is carried out after disconnecting the system from the network and extracting the coolant. Before the procedure, the pipes must be crushed (cleaned) of scale. Limescale, deposited on the inside of the pipes, reduces their permeability by fifty percent, increasing the load on the supercharger. It will become difficult for the pump to pump water through the system and it will quickly fail. The circulation is disturbed throughout the system. Heating will not be effective.

If the heating system is not pressed once every five years, then centrifugal pump will not cope with its task.

2.4 How to disassemble the unit?

In case of detection and elimination of malfunctions in the heating system, the equipment must be disassembled. For proper disassembly of the unit, the following rules must be observed:

- The pump is disconnected from the mains. When connecting the pump to the heating system, a bypass pipe is installed. In operating mode, the pipe shuts off. During repair, an auxiliary pump is connected. Installation of the pump provides the further functioning of heating.

- The valves are unscrewed, the unit is removed.

- The lid of the device is bolted to the body. With prolonged use, the pump heats up, and the bolts fasten to the body, it is impossible to unscrew them. The aerosol “liquid keys” copes with the problem. It is applied to the bolt and after ten minutes it is easy to unscrew.

- To access the inside, the housing cover is removed. The rotor, wheel and blades are unscrewed.

- Do it yourself and repair.

After disassembling the unit, the parts are cleaned and lubricated. Broken-repaired. Unrepairable are changing.

If the breakdown is connected with the wiring, it is better to entrust the repair to the master.

After the repair of the circulation pump for heating is completed, assembly and installation are carried out in compliance with safety regulations.

Having studied the design and features of breakdowns, repair of circulation electric pumps for heating with your own hands will not create problems.

Circulation pump is a unit that performs the function of forced circulation of the coolant in heating systems of closed and open types. The use of this unit accelerates the flow rate of water in heating radiators, due to which the indoor air heats up faster and more evenly.

The circulation pulser consists of a stainless steel casing in which an electrical unit is fixed. The design of the latter includes a rotor located inside the stator winding.

An impeller mounted on the rotor shaft is included in the circulation pump device. When electricity is supplied, the impeller rotates, which leads to the absorption of the coolant on one side of the pump and its expulsion on the other side. The pressure generated by the unit suppresses the hydraulic resistance of the nodes of the heating system, which leads to an increase in the speed of movement of the coolant.

The principle of operation of the circulation pump

Operating principle pumping equipment for heating is based on the rotation of the impeller. At the moment of supply of electricity, the engine of the unit starts, which drives the working shaft and the impeller fixed on it. The coolant enters the device through the suction pipe. In the working chamber, the liquid lends itself to the effect of the impeller, and accelerates, after which it enters the ejection pipe.

The circulation pump increases the efficiency of the heating system, since the heating of residential premises begins within a couple of minutes after starting the boiler. Correct installation of both industrial and domestic pumps for heating systems will reduce their maintenance costs - in practice, gas savings will approach 30%. Cost reduction is due to the fact that the heated coolant will faster reach the radiators and return to the boiler faster, having lost a minimum fraction of its temperature. Thus, slightly cooled liquid will be easier to heat up, and the boiler itself will be switched on for this much less frequently.

When choosing a circulation pump, a number of very important characteristics should be taken into account. These include:

- Power - usually for servicing large private houses you need to choose medium and high power devices. If the house has only one floor of several rooms, then a pump with a small capacity is quite enough for its heating;

- The maximum permissible coolant temperature is a very important parameter, which is always indicated in the pump certificate. Using the unit to hot water, it is always necessary to control that the temperature of the liquid does not exceed the maximum permissible norm. You can adjust the level of water heating on the boiler of the heating system;

- Pipe diameter - this parameter indicates what diameter of the pipe can be connected to the device for water supply at home;

- Head - this parameter indicates how far the pump will push the coolant. As a rule, household units are able to create a pressure in the range from 20 to 60 m;

- Productivity is the amount of fluid that the circulation pump sucks and pushes out for a certain period of work. To calculate this indicator, you should take into account the total area of \u200b\u200bthe heated rooms and select the appropriate unit;

- The presence of automation - most modern pumps for hot water supply have built-in protective devices that turn off the unit when the pressure and other parameters in the system change. On sale you can find pumps with a thermostat, with protection against dry running and other useful functions;

- Pump dimensions - it is important to remember that a small unit is not able to service large areas of a house. At the same time, mini pumps practically do not make noise during operation and consume less electricity.

Having studied all these parameters, it will be much easier for the buyer to choose a circulation pump. Knowing the characteristics of the unit will save you money and time.

How to install the circulation pump in the heating system correctly?

Before connecting the circulation pump, you will need to choose a place for its installation. It should be remembered that the pump needs to be controlled and regularly serviced, so it must be freely accessible.

Before connecting the circulation pump, you will need to choose a place for its installation. It should be remembered that the pump needs to be controlled and regularly serviced, so it must be freely accessible.

The most suitable place for installing the pump is the area in front of the boiler of the heating system. This is due to the fact that over time, air begins to accumulate at the top of the boiler. If you install a circulation water pump on the flow of coolant to the boiler, this will lead to the formation of vacuum in the upper part of the boiler. If you install the pump in front of the boiler, it will push the liquid into it, thereby eliminating the possibility of air congestion. Another plus of this method is that the pump will work with a coolant with a lower temperature, which will significantly extend the life of the device.

One more important point mounting a surface circulation pump is the position of its working shaft. It must be remembered that the shaft of the unit must be installed clearly in a horizontal position. Otherwise, the pump will not be completely immersed in water, which will lead to a significant loss in productivity.

Taking into account all these factors, you can proceed directly to the installation of the device with your own hands. The procedure is as follows:

- A bypass line should be installed in the selected section of the pipeline - bypass. Thus, the coolant will continue to circulate through the main pipeline even in the event of a power outage or a pump breakdown. It should be remembered that the diameter of the bypass should be slightly less than the diameter of the main pipeline;

- Before the pump, you need to install a filter that will protect the unit from getting small solid particles into it;

- On both sides of the pump, it is necessary to mount the pressure valves in the form of one double ball valve and a check valve. Their presence will allow for the dismantling and repair of equipment without draining the coolant from it. Both the tap and the non-return valve are mounted using a flange connection. As a result, you should get this scheme:

- Having completed all the necessary connections, you need to connect electrical power to the pump.

After connecting the circulation pump to the heating system, you need to test the equipment. The first few hours of operation of the pump should pass under conditions of low pressure and low productivity. Further, the pressure can be gradually increased until the heating system works in the usual conditions.

Circulation pump malfunctions - causes breakdowns

There are a number of typical malfunctions that owners of circulation pumps most often encounter. Among them stand out:

- The unit makes a noise, but there is no rotation - the cause of this problem is most often the oxidation of the motor shaft due to prolonged shutdown of the unit;

- The pump does not rotate and does not make noise - the problem is due to lack of power supply or too low voltage. To understand the breakdown, you need to use a tester and check the voltage at the terminals;

- The device starts up, but turns off after a couple of minutes - the reason is the accumulation of scale between the rotor and the stator. The problem can be solved by dismantling the motor and thoroughly cleaning it from limestone;

- The unit began to buzz very much at startup - the malfunction is due to air congestion in a certain part of the pipeline;

- The equipment creates a strong vibration - the problem is associated with the complete wear of the bearing, which is responsible for the rotation of the impeller. Repair damage by replacing a worn part.

It is quite simple to repair the device at home. Below, we consider methods for eliminating each of the failures in more detail.

Circulation heating pump makes noise - do-it-yourself solution

To solve this problem, first of all, you will need to let out all the air that has accumulated in the pipeline and radiators. To spend less time on this procedure in the future, experts advise installing automation in the upper part of the pipeline.

If the noise of the circulation pump is accompanied by strong vibration, then it is necessary to increase the pressure at the coolant inlet to the unit. In some cases, the lack of pressure can be compensated by an increase in the volume of coolant.

The circulation pump heats up - causes and elimination

There are many reasons why the unit can heat up. Among them, it is necessary to highlight:

- Incorrect installation - to determine that the unit is heating precisely for this reason is quite simple - the device will warm up already at the beginning of operation;

- Accumulation of solid particles in the system - with each month, particles of limestone and rust are deposited inside the pipeline, as a result of which the diameter of the pipes becomes smaller. Because of this, the unit begins to work in conditions of increased load. To get rid of this problem will help complete cleaning of the pipes of the heating system;

- Too little grease in the pump bearings - because of this, the bearing erases many times faster than under normal conditions. In this case, the device must be removed and refilled with new grease;

- Features of the pump model - some devices were originally made in such a way that they can heat up more than their counterparts. As a rule, this applies more to industrial units, but sometimes there are also household appliances;

- Low voltage in the network - if this indicator is lower than the declared 220 V, the motor of the device starts to heat up, which leads to its breakdown. To prevent damage, it is better to turn off the pump for a while.

No need to rush to dismantle the circulation pump and carry it in for repair. It is quite possible that the reason for heating is not even in the device itself. First of all, you need to measure the voltage of the network. If this indicator is normal, then the pipeline should be flushed with caustic soda. The liquid must be left in the pipes for at least an hour, and then drained. If this procedure does not help, then you will need to seek help from specialists.

What to do if the device buzzes but does not turn?

This problem is faced by those owners of pumps who do not often use appliances and who ignore the need to service the heating system. To fix the problem, you will need:

- Turn off the power to the unit;

- Drain the coolant from the pump and pipes adjacent to it;

- Remove the screws that secure the motor housing;

- Remove the engine with the rotor;

- Turn the rotor with a screwdriver, resting against the notch.

If the cause of the failure lies in the ingress of foreign objects into the device, then proceed in the following order:

- Turn off the power to the pump;

- Drain the water;

- Remove the screws holding the motor housing;

- Find and remove a foreign object;

- Install a strainer on the inlet pipe.

At the end of the repair, the device will start working again. The filter element will protect the device from solid particles, which will significantly extend the life of the entire system.

Circulation pump for heating

When solving the problems of heating a house, it is necessary to take into account the number of square meters. If the area of \u200b\u200bthe room is calculated in their hundreds, and not units, if the building has several floors, then the natural circulation system of the coolant will not cope with the tasks of heating. The pressure in such systems, as a rule, does not exceed 0.6 MPa, so it will be necessary to set it.

They will increase the efficiency of the described processes. Circulating devices are best suited for these purposes - only they are able to force the circulation of water and provide the expected result.

Circulation pumps - principle of operation

In its design, the circulation pump is similar to a drainage installation: the casing is made of stainless metals, has a ceramic rotor and a shaft equipped with an impeller.

The rotor drives an electric motor. Such a system draws water on one side and pumps it into the pipeline on the other. Centrifugal force helps water move through the system. The pump allows you to overcome the resistance that invariably occurs in individual sections of the heating pipeline.

Circulation devices are divided into two types:

- Dry

- Wet

Dry circulation pulsers

Device for domestic heating systems

In the first type, the rotor does not come in contact with the water that the pump pumps. Its entire “working” surface is separated from the electric motor by special protective rings. They are well polished and carefully adjusted to each other.

Dry circulation pumps are more efficient, but they produce very loud noise during operation. Therefore, most often they are installed only in a separate, well-insulated room.

Choosing the described model, it is necessary to take into account the fact that during operation such an aggregate creates air turbulences. Raised up dust particles can easily get inside and damage the o-rings, violate their tightness. Then the whole system will fail. Therefore, manufacturers took care of protection - between the rings there is always a thin layer of water film. It plays the role of a lubricant that prevents the destruction of the seal rings.

According to the individual structural elements, dry circulation pumps can also be divided into three types:

- Cantilever.

- Vertical.

- Blocky.

For cantilever circulation devices, the suction pipe is located on the outside of the cochlea, and the discharge pipe is on the body in the radially opposite side.

For vertical units, the nozzles are located on the same axis. They are called so, because the electric motor is not located in a horizontal position, as in the first case, but in a vertical one. Pumps of this type are installed if there is a need to pump a large volume of water.

Wet Type Circulation Pumps

Wet rotor pump

This type of pump differs from other models in that the rotor with the impeller are in the fluid that the unit is pumping. Moreover, the part where the electric motor is located is reliably sealed with a metal cup separating the rotor and starter.

Such a device is best suited for small heating systems. It produces less noise, does not require additional maintenance, it is much easier to repair and, if necessary, adjust settings.

The only drawback is the low efficiency. This is due to the fact that it is not possible to provide sealing of the sleeve that separates the stator and the coolant. That is why when installing the heating system of a private house, grandfos with a wet rotor and a protected stator are used.

Models of the latest generation are equipped with smart automation. It allows you to switch the level of the windings and increase the productivity of the unit. Most often, such models are chosen for a stable or slightly changing water flow. Step-by-step adjustment helps to choose the optimal operating modes, which means it saves energy consumption, ensuring the operation of pumping equipment.

How to install the circulation pump?

Pump installation

To prevent circulation in the heating system, it is necessary to select the correct location of the pump. It is necessary to find where in the water intake zone the hydraulic pressure will always be excessive. There are several ways to artificially simulate this condition.

The first way is to raise the expansion tank 80 cm from the highest point in the pipeline. This can only be done if there is a good room height. It is advisable to install an expansion tank in the attic, but then it will have to be additionally insulated for the winter.

The second way is to transfer the handset from expansion tank from the falling riser and cut it into the return pipe - to where the suction pipe of the circulation pump stands nearby. As a result of such a permutation, ideal conditions for forced circulation are created.

The third way is to insert the circulation pump into the supply pipe, right behind the water inlet point of the expansion tank. But this can only be done if the equipment model is able to withstand the highest temperature of the coolant.

And the last one. It is important to correctly calculate the motor power. If a motor of greater power than necessary is inserted into the heating system, the pipes will constantly make noise. Therefore, before installing, you need to know how much water passes through the boiler in a minute, take into account the diameter of existing pipes and the speed of water movement. For this, there are universal formulas that make it easier to choose a pump.