High pressure water pump for home. Choose a flow pump

Automation of pumping units for water allows the owner to solve a number of problems. Firstly, such an electric pump works autonomously and does not require constant attention from the user. Secondly, the device automatically maintains the required pressure level. As a result of this, an even flow of liquid is ensured without jerking and the entire system is operated more carefully.

Moreover, if you buy an automatic pump, for some reason it is not possible, you can automate any water pump yourself using special devices.

1 Features of the automatic pump

Regardless of type, automatic pumping devices have similar tasks. All additional sensors and automation systems protect the pumps from:

In addition, with the help of automation it is possible to achieve a more even flow of fluid to the points of water consumption, while maintaining a constant level of pressure in the line.

The principle of operation of pumping automation depends on the specific type of device. Such automation is located relative pumping device in the following options:

- built into the pump (pressure boosting pump, surface models for irrigation);

- the mechanism is connected by contacts with the motor and is located in close proximity ( drainage pumps for water disposal);

- the device is part of the system and is installed on the pressure pipe ( pumping stations for a private house).

In the course of operation, the sensors are in contact either with the pumped medium, or they monitor the status of the working components of the device (capacitors and thermal relays).

2 Types of automatic pumps and equipment

The type of operation of the device, as well as the features of the electric pump, depend on the type of automation mechanisms. Various manufacturers with a worldwide reputation offer a wide range of solutions for the automation of pumping equipment. But, most often, already tested, reliable schemes are used. The most widespread distribution in this regard are two types of devices:

- automatic pump;

- equipment providing autonomous operation and protection of standard models.

- automatic pressure pump;

- pumping station for home;

- step-up apparatus for heating lines.

2.1 Principle of operation of the pressure pump

Such pumps are universal surface units with a centrifugal principle of action. They are used for irrigation, in drip irrigation systems, for a stationary water supply line, or as a drainage apparatus for clean rain water. The undisputed leader in this segment of pumping units is Gardena. The company's equipment has built-in mechanisms for autonomous operation and a convenient tuning system.

In this type of equipment, two types of automation are used at once:

- built-in pressure regulator;

- thermal relay.

The first mechanism involves constant monitoring of the water pressure for the pump. The design of the regulator includes an elastic membrane, a large (maybe two) and a small spring, a set of contacts. The contacts are directly connected to the motor and are part of a common electrical circuit. A large spring is responsible for the maximum pressure threshold, upon reaching which, the device is turned off. A small spring determines the difference between the on and off threshold.

In the normal state of the water supply (irrigation) line, a constant pressure level is maintained in it. Water presses on the spring, the contacts do not close and the electric pump is not active. When the tap opens, the hearth moves out of the line, the pressure level drops sharply. As a result, the spring loosens and closes the contact of the circuit, which leads to the inclusion of the pump. The device works until the water level returns to normal.

Used in the device, the thermal relay belongs to the bimetallic type. It consists of two connected metal plates and a mechanism separating the contact group. Moreover, one metal plate has a greater heat sensitivity, and the second a smaller one. Under the influence of the high temperature of the pumped medium, the engine temperature rises, and this increases the temperature of the thermocouple (plates). The plates are bent to the side of less sensitive and thus press on the bar, which releases the contacts of the mains, and knocks the machine.

Gardena brand automated pumping units are usually made of plastic. A special display and a number of buttons on individual models allow you to adjust the value of the sensors and the operating mode. The device is lightweight, which allows it to be transported mobile to a new place of work or, supplemented by a pipeline, to provide stationary use.

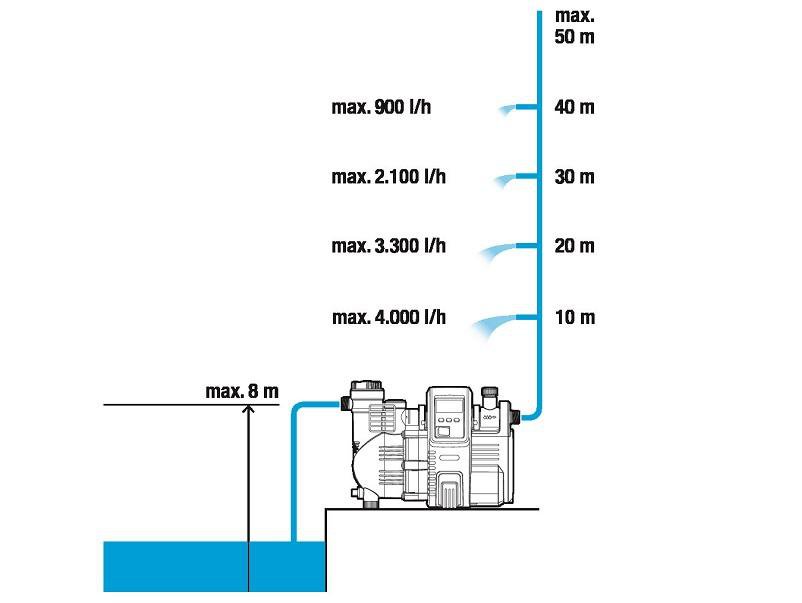

The productivity of such plants is from 3.5 to 6 thousand l / h. The electric motor power is in the range of 800-1300 watts. The depth of suction of devices is from 5 to 8 m.

In addition to the Gardena brand, Karcher and DAB pumps are also popular with customers.

2.2 Automatic water supply system based on the Patriot pump (video)

2.3 Pumping stations for autonomous water supply

Autonomous water stations are a more complex structure that provides an exclusively stationary home water supply circuit. As a basis, in such installations a surface pressure pump is used without automation or with already built-in sensors. Also, the system is mandatory supplemented by a hydraulic accumulator, a stationary pipeline, measuring instruments and additional sensors. Some models also include a fine filter.

The hydraulic accumulator is a volumetric tank with a membrane that regulates the pressure inside the line. As a measuring device, a standard or electronic pressure gauge is used that implements external diagnostics of the line condition.

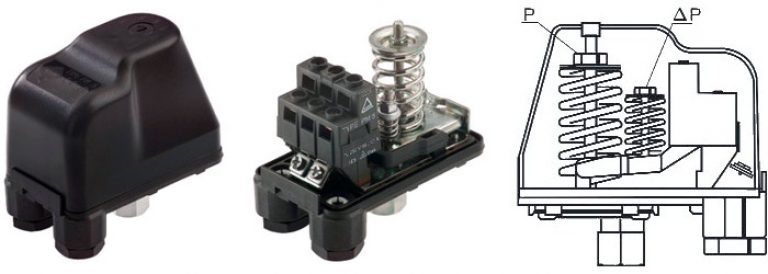

With regard to automation, then most often a pressure switch is used with stations. Moreover, on individual devices, the relay is already included in the pump design, and secondly, it goes as a component and is installed in the pipeline. The second type of relay is a separate unit. The necessary values \u200b\u200bfor the shutdown threshold or threshold for turning on the pump are set manually on the unit itself. For this, screws are used to fix the springs.

Regulator in such options pumping equipment installed, as a rule, on the pressure pipe, near the accumulator. This installation option provides the most accurate information about the pressure level, since the fluid flow here is as even as possible. Some models have special connectors for an additional pressure gauge.

The most popular in this category are manufacturers' devices:

- Dzhileks (productivity - 60-70 l / min, pressure - up to 50 m);

- DAB (productivity - up to 70 l / min, pressure - up to 40 m);

- Gardena (productivity - 40-50 l / min, pressure - up to 40 m);

- General Pump (separate models provide productivity - up to 80 l / min, pressure - 50 m).

2.4 Circulation pumps with automation

This segment is represented by cast-iron or bronze devices, which are used to increase the circulation of fluids inside heating and water circuits. The device consists of a working chamber, on top of which an insulated electric motor is located. A centrifugal wheel with blades is located in the working chamber, which accelerates the flow of liquid. The suction and injection of fluid is due to, located opposite each other, pipes. The device crashes directly into the pipeline.

As an automation element on such models, special magnetic flow switches are used. The sensor consists of a tube of small diameter, a plastic valve with a fixed magnet, a reed switch and a second, large magnet. A reed switch is located above the handset. It is completely isolated from water. The valve is inside the tube. A large magnet is built into the bottom of the cylinder.

When water enters the pump, and accordingly into the cylinder, it begins to put pressure on the valve. The valve rotates and brings the magnet to the switch. Under the action of the created field, a reed switch is activated and the pump is turned on. When the water level drops. The opposite magnet pulls the valve, the contacts open and the device turns off.

Most pumps of this type involve switching three operating modes, each of which is distinguished by its pressure characteristic and performance. Some models have digital screens and buttons.

3 Float switches

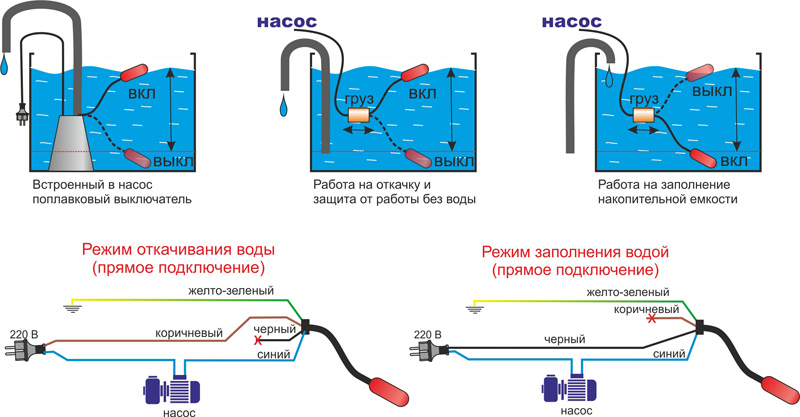

A separate category of mechanisms for automation is a float switch. Such a design is an element of automatic drainage electric pumps, or is installed on a submersible device that is easy to complete. The device is regulated by the liquid level in the source.

The float switch is represented by a plastic float, an electric cable, a contact group and a ball, which are located inside the float. The float itself is hermetically sealed and insulated with a polymer resin. Inside it there are three wires (brown, blue, black), two of which are closed with a metal ball, when the float reaches the desired level. The third wire is insulated. If necessary, changing contacts allows you to set other operating modes.

The principle of operation of the device is as follows:

- The float floats freely in the liquid. When its amount rises to a certain norm (regulated by a weight in some models), the lever is triggered, the ball closes the contacts. In this case, the electric pump is turned on and pumps the liquid out of the tank.

- When the water level reaches a critical point, the ball rolls back, opens the contacts and makes the device turn off.

Depending on the model, the trip threshold may vary. Some manufacturers produce mechanisms designed to shut off when the liquid drops to 5 mm.

The float mechanism is used at ambient temperatures from 0 to 60 degrees. In this case, the electric cable of the device is directly mounted to the contact group of the engine. The float is the cheapest automation option for pumping equipment.

If the house is equipped with a water supply, it is easy to imagine that water runs through the system. However, this is not always the case. Sometimes, due to the weak pressure of water, household appliances in the house simply refuse to work. And similar situations happen quite often in high-rise buildings. It is in these houses that water rarely reaches the upper floors. Therefore, in such cases, it is recommended to use pumps to increase the water pressure. I must say that such devices are also used in a private house. Therefore, today with the portal we will find out how these devices work and what they are.

When will the water

Each water supply system must have a certain pressure of water. The water pressure in the water supply is measured in bars. The unit of measure is 1 bar, which is equivalent to 1 atmosphere. The standard pressure of water in each water supply should be equal to 4 atmospheres. If such pressure is observed in the water supply system, then the water supply will be normal at any point in the water supply.

Today, many modern water supply systems have a pressure that ranges from 2-7 atmospheres. I must say that over-pressure is not scary. But plumbing with a low level of pressure can cause a lot of trouble. And only a high-pressure pump can improve the situation for the better, which is very easy to buy today.

How is the high pressure pump

The water pump, which is designed to increase the water in the water supply system, works with the help of a small electric motor. The pump rotates during operation thereby pumping pressure in the pipes. The pump is also equipped with a plastic casing, which has a very small size.

Special household pumps today, some people even install on household appliances. For example, quite often, such devices are connected to a pipe that delivers water to a boiler or washing machine.

Before you buy such a pump to fix a problem in the water supply system, you need to evaluate all the problems that the water supply in your private house has. You need to do this in order to choose right pump to increase the pressure in the water system.

It is worth saying that today there are two main problems that cause weak pressure in the pipes.

- There is water in the water supply, but the pressure is not strong enough. And enough water to just wash.

- The neighbors have water, but in your apartment there is absolutely no pressure on top.

Now you need to deal with the above problems in order.

So, if you are concerned about the problem of low pressure in the pipes, then do not worry. After all, this problem is easily solved. To solve this situation, you should buy a high-pressure pump, which must be cut into a common pipe that supplies water to your apartment.

It is worth saying that such devices are small in size and have a favorable price. A small electric motor acts as a driving mechanism here. In this case, the rotor and internal engine parts are cooled in one of two ways.

The next stand-alone device is a wet-rotor pump or flow pump to increase pressure in the water supply system. In this case, the lubrication of all elements of the pump occurs due to the passage of fluid through the chamber with the rotor. Therefore, such devices do not require maintenance. All that is needed for their quality work is a competent connection to the system and the correct installation.

The pump for increasing water pressure, which has a dry rotor, is characterized by increased power. It is worth saying that this device needs constant maintenance. During operation, the device produces quiet sounds that are similar to a squeak of a mosquito. In such equipment, all parts are fenced with a waterproof damper. Important parts of the device are recommended to be cleaned once every few months.

According to the type of operating mode, these pumps are divided into two types.

According to the type of operating mode, these pumps are divided into two types.

- So, the first version of the equipment is a pump, which increases the pressure in manual control mode. This device is characterized by continuous operation. Also, such pumps have a minimum of automation. In addition, they are distinguished by a simple design. Similar devices are used in underfloor heating systems.

- The automatic water pressure increase pump only works when the tap is turned on. Indeed, the pump starts to work only after at least one tap has been opened in the system. After closing the tap, this type of pump stops working. Today, such devices are the most popular devices. Such popularity is explained by the fact that such pumps consume a small amount of energy and subtly respond to any situation. The automatic pump is also notable for overpriced. Therefore, this should be remembered by every buyer.

How to choose a water pump

So, before you go to buy a new pump, you need to understand how the water enters the apartment. For example, if the tap water flows slightly, then you need to purchase a boost pump. And if only neighbors have water, and does not rise above, then it is worth buying a self-priming pump station.

To purchase a high quality pump, you need to evaluate the manufacturers of this equipment. It must be said that this moment is the most important when choosing a pump. Indeed, in the event of a breakdown, the pump will have to be repaired. Today, mainly devices from popular manufacturers take repair. Pumps of Chinese companies are not being repaired today.

Today, the most popular are high pressure pumps from manufacturers:

- Grundfos;

- Wilo;

- Sprut

When buying a pump, you need to remember that each company specializes in producing specific models. For example, a pump from the company Grundfos has a small volume and circulating system work. And all because such a company made a bet on the launch of these particular models.

But the pumps from the company Wilo are small in size. In addition, some models have a built-in

In general, many experts recommend that you carefully consider your choice. After all, if there is absolutely no water in the tap, then a simple pump will not solve the problem. A powerful pumping station will help to solve the problem here. However, you will have to pay a lot of money for such a device.

A pump that increases the pressure in the water supply is suitable if there is a weak pressure of water in the pipes. Such a device in this case is the best solution. And all because the device has a low price and high performance.

Device connection

After choosing the right device, you need to find the answer to the question of how to connect a high pressure pump.

So, first of all, it must be said that the pumping stations must be installed by a specialist. Self-assembly of the device is not recommended. And all because connecting such a device is not only a long, but also a complex process.

If installing a station is a complex process, then connecting the pump is very simple. All that is required of you is to shut off the water in the desired area and cut the equipment into the water supply.

So, to install the pump you need:

- First turn off the water in the required section of the pipe.

- Then it is worth releasing water.

- A field of which it is necessary to cut off the pipes and attach fittings and nozzles to it.

- After installing the nozzles, you need to mount the pump in the pipe. In this case, the inlet must be hooked to another part of the pipe. It is worth saying that at this stage, perhaps the introduction of a polypropylene or rubber hose into the system. These hoses are usually sold complete with the device itself.

- At the last stage, the water supply is connected to the main network or to the well.

A flow pump for increasing pressure is a fairly common type of household equipment. Many people face the problem of not enough strong pressure in their home, because of this there is a lot of inconvenience.

This makes it impossible for some household appliances to work, showering or washing up dishes becomes quite difficult.

Weak head problem

Although the presence of a water supply system should itself presuppose the presence of water in the tap, but in reality this does not always happen. If the pressure is too weak, household appliances may either not work or work for a very long time.

If we are talking about high-rise buildings, then the water may not reach the upper floors, to eliminate such problems, pumps are used to increase pressure.

Pressure is measured in atmospheres, 1 atm \u003d 10.19 meters of water. According to accepted standards, the pressure in the city water supply is 4 atm, but in reality it does not always comply with the standards. Excessive pressure of 6-7 atm leads to damage to household appliances, depressurization of pipes, the consequences of low pressure have been mentioned above. If the pressure is only 2 atmospheres, dishwashing machines cannot work normally.

Most home appliances require a pressure of 1.5-2.4 atm, fire extinguishing systems need three atmospheres. Before making a choice, you need to specify the problem.

If the tap has a low pressure, the flow pump will increase the pressure. If pressure does not reach the upper floors of tall buildings, and similar problems are not observed on the lower floors, then a full-fledged pumping station is needed.

Therefore, before choosing the type of pumping equipment, you need to make sure that the clogged pipes are not the cause of the weak pressure.

Classification of models

The flow pump for increasing pressure is divided into two main types. The first are small devices that are included in the water supply. They automatically maintain high pressure so that the water supply system supplies more water than usual.

The second variety is more complex, it is a high-pressure flow pump, supplemented by a hydraulic accumulator. Units are able to work in manual or automatic mode. In the first case, the operation is continuous, it constantly pumps up pressure and provides water supply, however, it is necessary to monitor it, otherwise the equipment may overheat and fail.

Automatic mode, in which the flow sensor monitors the operation of the device. As soon as the room starts consuming water, it will start working. This mode is preferable because it provides economical energy consumption, and will not allow the unit to work in the complete absence of water in the tap, which significantly extends the service life.

Pumps for increasing the pressure of running water can be classified by cooling technology.

In the first case, cooling is carried out by means of blades fixed on the shaft, the system with a dry rotor emits some noise during operation, but it is more efficient.

The second option is cooling through the pumped liquid. During operation, the device is cooled by the water that it passes through itself, thanks to this the device is almost no noise.

Criterias of choice

Before making a choice, you need to consider a few important points. The device should correspond to the tasks set, their characteristics should be evaluated, such as throughput and generated pressure. It is best to choose products manufactured by well-known manufacturers, the size of the room in which the pump will be installed, and its cost.

The necessary calculations can be made by specialists in this field, companies involved in the distribution of pumping equipment often offer this service without requiring additional payment.

For a slight increase in pressure in the system, 1.5 atmospheres is needed, a small pump is enough for this, it easily cuts into the water supply system, without taking up too much space.

More expensive devices take up more space; their installation in an apartment is far from always justified. In some situations, it will be more appropriate to install several not so powerful pumps that are connected in front of water-consuming equipment.

Popular models

Let's consider in more detail the most popular models.

It is important to remember that it will not be possible to select a flow pump that is completely suitable for the user to increase the pressure, since they are considered serial units with average parameters.

Therefore, it is necessary to select a device that is most suitable for its characteristics of the existing water supply system. Excessive power will lead to noise in the pipes, insufficient power will not satisfy the user's needs.

It is best to choose a device that will be 5-10% more powerful than the norm of a particular system.