Varieties of filters for mechanical treatment of water. Filter of mechanical water purification.

Mechanical cleaning is necessary where water does not meet the standard indicators of turbidity, transparency, color, taste and smell due to the presence of insoluble suspended particles of sand, clay, silt, colloidal iron and silicon, pipeline rust, scale and other impurities. Mechanical cleaning is the cheapest way to clean water and is used to isolate suspended matter.

The mechanical filter allows you to protect process equipment from clogging and premature failure in the subsequent stages of cleaning.

Mechanical purification of water is ensured by the capture of particles of undissolved substances due to the difference in sizes of the particles themselves and the filter channels through which the purified water flows. Simply put, water passes through a kind of "sieve".

The size of the particles retained by the filter is determined by the diameter of the channels in the water purifier material through which water flows (i.e., the size of the openings in the sieve).

For example, columns filled with granular activated carbon with a particle diameter of 0.1-1 mm (100-1000 microns) are capable of effectively retaining particles of approximately the same size. Most of the particles insoluble in water have a much smaller - 0.1-20 microns - size. True, microorganisms do not linger during mechanical filtration, since their size is 0.4 - 3 microns.

Mechanical water filtration is widely used at municipal water treatment plants. This type of treatment is especially relevant when taking water from open sources: rivers, lakes, reservoirs.

No less important characteristics for mechanical treatment of water are the size and type of filter media. You can select the necessary filter based on the turbidity of the water. There are two types of filtration in mechanical water purification: filtering and purification through film filtration.

If the first type of mechanical water treatment is based on the ability of the filter material to retain particles that are smaller than its pores, the film filtration method allows to achieve higher cleaning rates due to the fact that the filter material is coated with a film capable of retaining smaller particles.

The essence of the method of mechanical water purification is filtering, settling and filtering, due to which heavy impurities settle and are retained by the filter material, and light impurities, on the contrary, float to the surface, leaving more or less pure water in the middle.

In fact, mechanical treatment is only the preparation of water for deeper cleaning in other ways, whether chemical methods or biological. A sufficiently low degree of purity of water that has undergone mechanical treatment forces us to use more expensive and better methods. Due to mechanical filtration and sedimentation, about 60% of impurities are removed from water, which, of course, is not a satisfactory result.

Mechanical purification of water with recirculation by filtration as an independent method is used when clarified water after this purification method can be used in production processes or released into water bodies without violating their ecological state. In all other cases, mechanical cleaning is the first cleaning step. wastewater. However, today, for example, at oil depots, there are much more effective methods of mechanical purification of water, which allow you to remove most of the impurities from the water.

Filters for mechanical water treatment:

Mechanical water filters are usually installed at the inlet to the filtration system. They differ in principle of operation and type of construction.

The simplest device is strainers. They capture impurities using a metal or polymer mesh inserted into the flask, which has an inlet and an outlet connected to a water pipe. Depending on the size of the cells, filters trap particles of a certain size.

Strainers are washing (they must be disassembled and manually cleaned the removed mesh under a stream of water) and self-washing (have a jet washing mechanism without stopping the water supply and dismantling the mesh). An example of strainers is the products of HONEYWELL (USA - Germany) and DRUFI (Germany).

In disk filters, a set of polymer disks with grooves of a certain depth and width that correspond to the size of the trapped particles is used as a working element. Under the pressure of water, the disks are compressed, and a volumetric mesh structure is formed between them, which purifies the water passed through them.

Disc filters are characterized by increased dirt capacity (compared to mesh filters), high performance, and the fact that they are easily washed (manually or automatically) and completely restore their filtering ability. An example is the products of the company ARKAL (Israel).

The principle of operation of cartridge filters is based on adsorption. They purify water from smaller impurities (with a size of undissolved particles of 0.5-100 microns).

Sorption cartridge filters are cylindrical plastic flasks with replaceable filter elements made of fibrous synthetic materials. Cartridges are selected depending on the quality of the water and the required degree of its purification, changing after a few months of operation. The recognized leader in this water treatment technology is the US company US FILTER (formerly AMETEC).

To clean large volumes of water in cottages with all amenities, the so-called filling filters, which are tanks with bulk filtering materials, are used. Their advantage is that they can not only capture a larger amount of impurities, but also, unlike cartridges and strainers, work for years without replacement, undergoing periodic regeneration (washing) in automatic or semi-automatic mode.

The filtering materials are quartz sand or granular aluminum silicate. With their help, water is freed from mechanical particles with a size of 20–40 microns.

Mechanical treatment is a preliminary step in the processing of toxic water. The main purification from toxicity is carried out using further physicochemical and biological methods.

Mechanical filterDesigned to purify water from inorganic and organic particles in suspension in water when water passes through the filter material sand, gravel, porcelain, ceramics and clay products (expanded clay, porcelain tubes, etc.), synthetic material (cotton, fiber, foam, foam, etc.). In addition, it can aerate and circulate water in the aquarium.

Absorption (“absorb” - to absorb, absorb) filters are the same mechanical, but in them between the layers of the filter material is placed a layer of activated carbon or other substance that can absorb organic decomposition products, dyes or toxic substances from water. If peat or marble is added to the mechanical filter, it will regulate the hydrochemical regime, stabilize the pH, saturating the water with the necessary substances (calcium salts, humic acids, etc.). In addition, it can aerate and circulate water in the aquarium.

Depending on the speed of water passage, the filters are divided into fast and slow. Airlift is usually the source of water movement in slow filters. The principle of its operation is as follows: the air flow from the compressor in the form of small bubbles is mixed with water; the air-gas mixture rises in a narrow vertical channel (tube) above the water level in the aquarium. Thus, water is pumped through the tube, and the filter element can be installed at the entrance to the tube or at the exit from it.

In fast filters, the source of water movement is mechanical (most often centrifugal) water pumps (pumps). They create a high pressure of water, thereby providing a higher speed of its circulation through the filter element.

Bacteria that convert organic compounds to mineral ones settle on the surface of the filter element. However, since the volume of mechanical filters is small, complete decomposition of organic substances in them does not occur. Using mechanical filters, aquarists often make one mistake. When the filter is working, the microorganisms living in it oxidize organic compounds, for this they need a constant flow of oxygen. Some aquarists, at night, avoiding noise or following the instructions for use of the compressor, turn it off, stopping the supply of oxygen to the filter. In the absence of oxygen, instead of almost harmless substances, hydrogen sulfide H 2 S, methane CH 4, ammonia NH 3, which are highly toxic for fish, begin to be produced. During the stoppage of the filter, these substances accumulate in it, and when it is turned on again, they are immediately released into water in large quantities. This can lead to mass poisoning of fish or injuries associated with a jump in water parameters (primarily pH). Therefore, aquarists should not turn off working mechanical filters without rinsing or replacing the filter element.

Mechanical and absorption filters must be regularly, at least 1 time per month, cleaned, washed with filter media, replaced with absorbent material. In the process, a large amount of toxic substances is concentrated in them, and if not cleaned, they can cause fish poisoning.

After the filter stops working, for 1 day or more, it is necessary to rinse the filter material before turning it on, because anaerobic bacteria appear in it due to a lack of oxygen, and the water drained into the aquarium will be saturated with the toxic substances that they produce.

Now we dwell on the structural elements and technological features of the filters. Depending on the installation site, external and internal filters are distinguished.

The basic design of the internal mechanical filter is shown in Fig. 12. The filter consists of a housing (1) in which there are two openings: one large inlet (2) and the other outlet (3) of a smaller size. A sprayer connected to a compressor can be lowered into the output channel, thereby creating the simplest airlift. In this case, the diameter of the inlet channel should be slightly larger than the diameter of the atomizer. If you intend to attach a filter to the pump, then the design of the outlet must correspond to the diameter of the connecting hose and provide a reliable and tight connection to the pump. The inner cavity of the filter between the restriction gratings (4) is filled with a filter element (5). The filter element must completely fill this cavity, otherwise unfilled channels may form through which the main stream of water rushes.

Coarse sand, gravel, porous polystyrene foam, waterproof foam rubber, synthetic fibers or cotton wool are used as a filter element. The main thing is the chemical inertness of the material used, stability in water, the possibility of washing and replacing it.

External filters in action are no different from internal ones. Their advantages over internal ones are that they have a larger volume, do not clutter the aquarium, it is easier to replace or wash the filter element in them. When operating an outdoor filter, it is important to prevent it from overflowing with aquarium water. Therefore, usually, water is pumped from the filter to the aquarium, and returns by gravity through a spillway or through a U-shaped tube filled with water. In fig. 13 shows design options and methods for attaching external filters.

Fig. 12. Internal mechanical filter:

1 - housing, 2 - inlet

3 - outlet, 4 - restrictive grilles,

5 - filter element, 6 - airlift.

Fig. 13. External mechanical filter:

1 - U-shaped tube for supplying water to the filter

2 - airlift, 3 - filter element.

Biological filter

Biological filters are more complex designs. It has already been noted that in nature, self-purification of water occurs due to bacteria and other microorganisms, as a result of which the biological equilibrium in the reservoir is maintained. Since a complete self-purification of water is usually impossible in an aquarium, sooner or later (usually after 1 - 2 years) you have to completely change the water and wash the soil. The more fish there are in the aquarium, the more often you have to do it. Using a biofilter allows you to significantly delay the period of general cleaning of the aquarium.

A biological filter is a living organism. Water purification in it is carried out by microorganisms that settle on the surface of the biofilter filler, and consists of the following main stages: mineralization, nitrification and denitrification. In the process of life, various nitrogen-containing organic substances, for example, amino acids, as well as decay products, such as urea, accumulate in the aquarium water. One example of mineralization is the deamination process, during which ammonium is formed. Deamination of protein substances requires the participation of heterotrophic bacteria. After this, autotrophic bacteria that oxidize ammonium to nitrites and nitrates begin their activity, that is, they carry out the nitrification process - the next stage of biological treatment. Bacteria nitrosomonas oxidize ammonium to nitrites, and bacteria nitrobacter oxidize nitrites to nitrates. Nitrites and nitrates dissolved in water are reduced with the formation of ultimately free nitrogen, which is released into the atmosphere. The processes of reduction of nitrites and nitrates occur with the participation of heterotrophic bacteria - denitrifiers (for example, the pseudomonas bacteria), which, unlike the previous ones, can exist only in an anaerobic (oxygen-free) environment. Anaerobic conditions are created in the filter layers experiencing oxygen deficiency, as well as in the soil of the aquarium.

Fig 14. Biofilter circuit

How to determine the effectiveness of a biofilter? The processes of mineralization, nitrification, denitrification in a balanced aquarium occurs sequentially and interconnectedly. An indicator of high-quality water purification can be the concentration of ammonium, which should not exceed 0.1 mg / l.

In an aquarium equipped with a biofilter, it is unacceptable to add a number of medical preparations, since they can completely suppress the microflora of the biofilter. The most active in this regard are sulfanilamide, erythromycin, chlortetracycline, methylene blue, potassium permanganate. The optimum pH range for the biofilter is 7.0 - 8.0. Like any living organism, the biofilter is an active consumer of oxygen.

As a filler of a biofilter, it is best to use gravel with an optimal particle size of 2 - 5 mm, and it is desirable that the particles are angular, because they have a large surface compared to round ones. Smaller gravel will not allow water to pass well, while coarser gravel will have less surface area. The surface area of \u200b\u200bthe biofilter is crucial, it should be at least equal to the area of \u200b\u200bthe aquarium. The optimal thickness of the gravel layer is not more than 5 - 7.6 cm.

Biofilters are external and internal. The external biofilter can be made of plexiglass. It should consist of blowing compartments.

- Mechanical (rough) cleaning -ordinary mechanical filter. Perlon, nylon and other polymer fibers can serve as a filtering element; all this is placed in a removable cartridge for easy washing.

- Aeration tank - in it there is a saturation of water with oxygen, the primary oxidation of organic matter and its decomposition by various bacteria that accumulate in the compartment. The combination of these bacteria and other microorganisms is called activated sludge. The greatest cleaning effect is achieved when the sludge is in suspension and under very good oxygen conditions, so the mixing of water with the supplied air should be strong. With the development of filamentous algae in aeration tank, activated sludge swells (it becomes ill), therefore their presence is undesirable. At the exit, a layer of gravel is laid out from the aeration tank so that the sludge is not washed out.

- Actually biofilter - in it, water is purified by protozoa (infusoria, rotifers) and various primitive fungi, and the work of bacteria continues. The products of the metabolism of microorganisms, as well as the final decomposition products of organics and nitrogen-containing compounds, are removed by plants and algae. In this regard, the algae “cladofora” and houseplants “philodendron” and “chlorophytum” proved especially positive. The biofilter with plants needs bright lighting.

The biofilter device diagram is shown in Fig. 14. Water supply in the biofilter can be carried out by airlift or other pump. The water exchange must be such that in an hour from 50 to 100% of the volume of the aquarium is pumped through the biofilter.

Fig. 15. Internal biofilters with various options for supplying air to airlifts

Fig. 16. Scheme of the internal biofilter:

1 - body of a mechanical filter;

2, 3 - removable cover;

4 - cartridge with filtering material;

5 - soil aquarium;

6 - nylon mesh;

7 - perforated plate (false);

8 - airlift tube; 9 - sleeve;

10 - glass tube; 11 - thermal relay.

For most lovers, it is easier to make an internal biofilter. In this case, the aquarium itself is a biofilter, and a conventional mechanical filter turns into its compartment. The device of internal biofilters with various options for water supply. shown in figures 14, 15, 16. It consists of a mechanical filter housing with a removable cartridge filled with filter material, a “complex” bottom (perforated plexiglass plate), on which soil is laid, tubes that feed water from the mechanical filter under a “false” ”Bottom, and airlift and pump. Airlift delivers water from the aquarium to the mechanical filter section, while the water level in the section rises above the total water level in the aquarium by 10 - 15 cm. Water saturated with oxygen passing through the cassette is subjected to rough cleaning. Then it enters the soil and, passing through it, undergoes biological treatment. When using such a filter, an aquarium with a capacity of 100 l can work without washing the soil, completely changing the water; and with an average density of fish (2 - 3 liters per 1 fish 4 -5 cm long) for three years. In this case, care for the aquarium is greatly facilitated. It comes down to replacing 1/10 of the water and washing the filter cartridge once a week. Air may be supplied from the microcompressor. This filter is very efficient and requires minimal energy consumption.

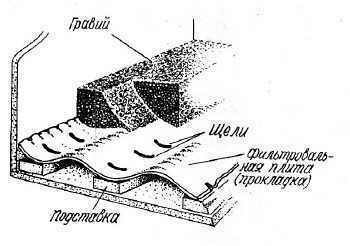

Fig. 17. Cross section of the aquarium showing the device filter plate (false) of corrugated fiberglass

I want to note to lovers of aquatic plants that such filters do not have a significant effect on plant growth. Biofilters are effective when the aquarium contains a large number of fish and relatively few plants. After all, higher plants themselves are wonderful “biological filters”, absorbing many organic substances, metabolic products, absorbing carbon dioxide and enriching water with oxygen.

Chemical filter

Chemical filtration removes toxic chemical products, such as ammonia, by adsorption (not to be confused with absorption, absorption) on a porous surface. The most common are activated carbon and zeolite, there are other means.

Chemical cleaning is a specific type, since it removes certain compounds from water for which the reagent used is intended. Chemical cleaning systems are used, for example, in the preparation of tap water and the removal of chlorine (as discussed above). For existing aquariums of particular interest is the type of chemical water purification associated with filtering it through activated carbon, ion-exchange resins, and some other substances.

Charcoal filters are mainly used to bleach water and remove nitrates, phenols, chlorine, pesticides and some other substances. The high absorption capacity of activated carbon is due to the porous surface. For example, the true surface of 1 g of high quality activated carbon is 200 - 500 m 2 100 g of activated carbon can extract up to 55 g of dissolved substances from water.

The adsorption capacity is influenced by various factors:

- pH and water temperature

- water flow rate

- concentration of substances

- particle size of the adsorbent and its quality.

The cleaning process in the carbon filter can be divided into two stages. At the first stage, adsorption of organic molecules and inorganic ions on coal particles sometimes occurs; at the second stage, some organic compounds are decomposed into minerals. So the processes of adsorption and biological treatment of water are combined.

Due to its high absorption capacity, activated carbon quickly clogs up, starts working like a simple mechanical filter and needs to be cleaned. To restore this filter, you need to boil activated carbon in distilled water for an hour, changing the water twice. Due to the complexity of restoring the adsorption capacity of coal at home and the lack of filters produced by the industry, they are not widely used among aquarists in our country. In some cases, the use of activated carbon filters is a necessity, for example, when keeping a saltwater aquarium or breeding fish that are very sensitive to water purity. In all cases, attention should be paid to the quality of coal.

In aquarium filters, ion-exchange resins (cation exchangers and anion exchangers) can be used, which are described in the chapter on water softening. To remove cations, for example, unwanted ammonium ions (NH 4 +), KU-2, KU-23 cation exchangers can be used. However, it must be remembered that along with these cations, others will also be removed, for example, Ca 2+, Md 2 + K +, etc.

Using ion-exchange resins (anion exchangers), for example, AB-17, it is possible to remove anions NO 2 -, NO 3 -, PO 4 - 3, SO 4 2 - and others. Preparation of cation exchangers and anion exchangers for use in filters is similar to that used before desalination, however, instead of hydrochloric acid and alkali solutions, a 5 - 10% solution of sodium chloride NaCl should be used here for the treatment of both types of resins.

The disadvantage of resins is their rapid contamination with organic substances. Therefore, to ensure the normal operation of the ion-exchange filter, water must first pass through a mechanical filter, and even better, through a biological filter.

As the fillers of the filters, which can carry out the chemical purification of water, horse peat should be mentioned. Peat filters are used in cases where it is necessary to obtain soft and acidic water and maintain it in this state. Using peat filler (periodically replacing it with fresh), water of very high hardness (20 ° dGH) can be turned into soft water (less than 4є) within 2 to 3 days.

Flotation water treatment

Flotation - removal of unwanted impurities from the water along with the resulting foam. This method, well known in the mining industry, has been successfully applied in aquarium practice.

The essence of the method is based on the ability of many substances to adsorb on the surface of gas bubbles passing through a liquid. Bubbles of gas rise to the surface of the liquid, forming a foam in which undesirable impurities are concentrated. Foam along with impurities is removed and thus the water is purified.

In fig. 18 is a diagram of a simple flotator. The principle of its work is as follows. Water from the aquarium through a mechanical filter continuously enters the flotator. Air from the compressor is supplied to the atomizer (1), after which it rises to the surface of the water in the form of a large number of small bubbles. Adsorption of mainly organic substances occurs on the surface of the bubbles. Foam forms on the surface of the flotator, which is retained by the foam trap (2) and carried out to a container to collect contaminants. Treated water is supplied to the aquarium or other cleaning devices. Flotation treatment is good to carry out before biological filtration.

Race 18. The filter for water purification:

1 - spray, 2 - foam.

Water disinfection

For the destruction of pathogenic forms in water ultraviolet and ozone disinfection.

Ultraviolet disinfection

Ultraviolet radiation with a wavelength of 200 - 280 nm destroys nucleic acid molecules in the nuclei of cells and leads to their death. It kills many bacteria, viruses and other microorganisms. The effectiveness of UV irradiation depends on the degree of water pollution, the thickness of its layer. the size of the exposed organisms, the intensity of exposure and its duration.

Water treatment with ultraviolet rays allows its disinfection: undesirable various microorganisms are destroyed, which develop in large numbers when a large number of fish are kept in a closed aquarium system. In this way, you can free water from bacteria, viruses, spores of fungi (saprolegnia, etc.) and some protozoa.

The dose of radiation received by the body is determined by multiplying the lamp power by the duration of exposure. Usually, the larger the body, the greater its lethal dose. So, for example, the lethal dose for unicellular organisms with radiation with a wavelength of about 250 nm is 1 W. s, for protozoa and those with increased resistance to fungi 10 times, for bacteria and other fungi 70 times and for viruses 300 times less.

Therefore, the UV sterilizer is used by installing it outside the aquarium after filters of mechanical and biological water purification. Each filter contains a different number of bacteria, and among them there can be all kinds of microorganisms and pathogens, so this way you can prevent them from entering the aquarium. With the right water flow rate providing the necessary dose of radiation, they will die in the sterilizer. But UV radiation does not have a therapeutic effect in the onset of the disease.

Fig. 19. Scheme of the UV sterilizer:

1 - lamp, 2 - casing,

3 - housing.

The UV sterilizer (Fig. 19) consists of a UV lamp (type BU V-15, etc.) (1) enclosed in a casing (2) made of quartz glass and a housing (3) with inlet and outlet pipes. Over time, the outer surface of the casing is covered with deposits of mineral salts and should be removed with hydrochloric acid.

The efficiency of ultraviolet devices above the UV sterilizer includes a metal or plastic casing (to protect the skin and eyes) with an emitter located inside it (BUV-15 lamp, etc.) mounted in a quartz flask with inlet and outlet nozzles water. Today, UV lamps built into a portable mechanical filter (Italian company “Sicce” and others) are becoming more widespread. When constructing a sterilizer on your own, it must be taken into account that ultraviolet rays do not penetrate to a depth of more than 5 cm. The penetrating ability of the rays reduces the biofilm covering over time the outer surface of the lamp glass. In turbid and saturated organic water, UV - sterilization becomes meaningless. The flow rate during disinfection should not be less than the volume of the system in bitches. The continuous life of UV lamps is 8,000 hours.

Less effective, but simpler is the so-called surface irradiator, consisting of a UV lamp with a reflector mounted at a height of 10 - 20 cm above a shallow trough through which water is passed, and its layer should not exceed 5 - 6 cm, because at a depth of 10 cm, the rays no longer work.

Irradiation in the ultraviolet region of the light achieves the greatest effect when combined with other types of water treatment, in particular with biofiltration.

Ozone disinfection

Ozone (O 3) is an unstable form of oxygen, the molecules of which consist of three atoms. The third atom is weakly bound and easily falls off in water. Thus, atomic and molecular oxygen is formed. A free atom has a strong oxidizing ability, killing bacteria, microbes, eggs, sperm, etc.

Ozonation destroys predominantly free-floating microflora and acquires special urgency in the soft, acidic water of tropical aquariums. With a contact duration of 5 to 10 minutes, the effective dose is 0.5 to 4 mg / l. For household use ultraviolet ozonizers, providing an ozone output of 1 - 10 mg / l, or 0.5 - 1 mg / h.

A significant advantage of ozonation is that ozone does not leave harmful substances in the water after treatment. Traces of this gas, toxic to aquatic organisms, are removed after a short time. It has been established, for example, that algae die at a concentration of O 3 in water of 0.5 - 1.0 mg / l; daphnia and cyclops - at a concentration of about 2 mg / l.

Fig. 20. Ozone filter:

1 - aquarium, 2 - filter housing

3 - activated carbon

4 - synthetic fiber

5 - spray

Ozonation of water should not be carried out in an aquarium, but in a separate vessel in order to avoid damage to the fish. Water from this vessel should be fed to the aquarium through a charcoal filter, with which traces of dissolved ozone are removed, preventing them from reaching the fish.

Ozonation of water is carried out in an external filter, then passing water through a layer of activated carbon, which eliminates the smallest traces of ozone from the water, while the water retains almost completely bactericidal properties (Fig. 20). The dose of ozone required for disinfection varies depending on the target, the content of organic substances in the water, the temperature and pH of the water and averages 0.5 to 4 mg / l.

V. Migulin (RiR 3/69) reports positive ozonation results for sterilizing water in a spawning aquarium and incubator. Water is ozonized for 15 to 20 minutes, and then aerated for the same time.

Ozonation of water is especially effective if it is combined with other methods of water purification. For example, water can be ozonized after flotators or biological filters.

The use of ozone in the foam separators of the aquarium is undesirable, since residual ozone is very toxic, and the saturation of water with oxygen can lead aquatic organisms to gas embolism.

When designing and manufacturing objects in which ozone is located, it should be noted that ozone and its aqueous solutions are extremely aggressive and destroy steel, cast iron, copper, rubber, ebonite. Of metals, stainless steel and aluminum should be used, which can stand for several years. Connecting tubes are made of polyvinyl chloride, etc. materials, seals are made of ethylene-propylene. Ceramics and glass are resistant to ozone.

The performance of the ozonizer can be determined as follows. 200 ml of distilled water and 0.5 ml of acetic acid are poured into a glass dish, a teaspoon of potassium iodide is added and, after stirring, the solution is poured into a glass flask of the smallest diameter, at the bottom of which there is a nebulizer connected by a tube to an ozonizer. The solution is ozonized for an hour (a few minutes after turning on the ozonizer, the solution becomes brown). Then, 1 cm 3 of starch is introduced into the solution, while it acquires a blue color, and is titrated with sodium thiosulfate until brightened. The amount of thiosulfate used for titration in mg is multiplied by 1.2 and the approximate productivity of the ozonizer in mg / h is obtained.

Based on the foregoing, we can draw the following conclusions: intensive cleaning frees up the medium from mechanical suspension, toxic substances of organic decay and pathogenic microorganisms. Allows to minimize labor costs for maintenance of the aquarium; reduces consumption of water - a valuable national economic raw material; creates comfortable conditions for the maintenance and reproduction of aquatic animals and plants; significantly increases the decorative effect.

From mechanical impurities - one of the most common things that can be encountered when consuming water even from the water supply system (which has already passed the water treatment stage, ideally) There are many options for how to deal with such pollution.

1.1 Types of filters for cleaning water from solids

Another flushing type filter, ½ inch inlet diameter

The main types are as follows:

- Coarse cleaning methods are used (particles from 20 to 100 microns in size are removed);

- Fine cleaning methods are applied (they purify water from particles 1-5 microns in size).

Separately consider the so-called "mud filters" (including industrial), whose task is to keep dirt from entering the system (here we are not talking about fine cleaning, they can be used when supplying water from the well).

In this case, the filters are mounted mainly at the exit from the well. This is done so that the water is cleaned at the approaches of the well, and already enters the system in a suitable form.

In the case of using the well as a source of water, the coarse main filter will be indispensable in the water treatment system (as well as fine filters).

Filter cleaning methods subdivide them into:

- Flushing (usually - main);

- Flush (usually used cartridge).

A feature of filters in which a cartridge is used (including fine cleaning) is precisely the inability to wash the filter cartridge; after the end of its use, it must be replaced.

At the same time, cartridges for filtering hot and cold water are not interchangeable, since the temperature is higher than that for which the housing is designed to deform it or the cartridge.

In addition, it must be borne in mind that the life of the cartridge may vary depending on the composition of the water, and if necessary, it will be necessary to replace the water supply.

The washing filter (including the main one) involves certain methods of cleaning the filter element.

The same blocks for hot water usually opaque and metallic. The transparent case of the filter for cold water sometimes allows you to "assess its condition by eye".

2 How to choose a mechanical washing filter?

If you buy a main filter for hot or cold water, using rough or fine cleaning methods, for domestic use, a model with the possibility of backwashing will be more convenient (it is also suitable for supplying water from a well).

Despite the fact that the main filter can be washed in one way or another without turning off the system, it is recommended to flush the grid separately (that is, to still turn off the system for a while), but this is done much less often than changing the cartridge.

If we compare the types of filters (regardless of whether they are intended for hot or cold water and what methods are used) - mesh or disk - it is often mentioned that the disk type of the filter under similar conditions has greater performance due to the larger filtration area.

But, only the difference in the size of the filtration unit can provide a big gain, and with similar sizes, both the strainer and the disk filters show the same indicators for the water passed through them (including in the case of fine cleaning).

At the same time, a coarse or fine filter may turn out to be more demanding on the pressure of the incoming water than a strainer, and also be more expensive.

Before buying, you should decide on the parameters of the system on which the filter will be installed, using rough cleaning methods, and it is planned to use it for hot or cold water.

If the main filter is installed separately, it is necessary to check that the pipe connections and the diameter of the pipe and filter connections are compatible (or care about fitting them).

If a cartridge filter is installed in a block filtration system, care must be taken to ensure that all blocks are compatible.

Accordingly, the choice is based on the following parameters:

- Whether the filter is separate or it will be installed in a multi-stage system. Sometimes the main filter is installed on the pipeline in a separate apartment, for example;

- What type of filter will be installed and is it compatible with the piping system (filter working methods);

- Depending on the type selected, the manufacturer and cost are determined.

From directly products of various manufacturers, mention may be made of filters (coarse and fine cleaning) Honeywell or Atlas, and from manufacturers of the CIS countries - the Russian Geyser.

Danwell Honeywell products are reliable and build quality. Honeywell filters of this type are typically equipped with a backwash system. And also from Honeywell filters one can expect additional equipment (with a built-in pressure gauge, for example).

Honeywell filters also have great durability and resistance to pressure drops, because the filter housing is made of durable brass (a feature of this Honeywell product). The downside here can only be the cost, that is, less Honeywell filters are less accessible.

Geyser water purification filters, according to the manufacturer, compete with European counterparts and are used both in Russia and in Europe.

Under the Geyser brand, both individual types of filters for mechanical cleaning and entire systems for various purposes are produced (complex water treatment for cottages and country houses, cleaning technology for enterprises).

As a result, several specialized Geyser solutions compete with more universal analogues. The Geyser company produces both strainers and filters where a cartridge is used. A comparative advantage of the Geyser is also the price (compared to the previous manufacturer).

Thus, Geyser products will be a more budget option. Therefore, choosing between a Geyser and a Honeywell, we will prefer a Geyser in cost, and Honeywell in quality.

2.1 Demonstration of the operation of the washing filter (video)

Currently, all water bodies on our planet are highly polluted, which negatively affects the environmental situation and human health. Everyone knows that eating contaminated water from rivers and lakes is very dangerous.

Before entering residential premises, water must go through several stages of purification, which allow to get rid of harmful impurities as much as possible. At the first stage, mechanical water treatment is most often used.

Mechanical cleaning consists in passing liquid through special filters that separate large particles of contaminants.

Accordingly, the more filter materials are used, the cleaner the water comes out after this process.

If these parts are not removed from the water used, then they can have a detrimental effect not only on the human body, but also on taps, mixers, washing machines.

Using a mechanical water purification filter, you can get rid of:

- mechanical impurities, such as particles of sand, clay, silt, rust, affecting turbidity of the water;

- organic and mineral impurities that color water in various colors;

- petroleum products and other organic compounds that affect the smell and taste of water.

Mechanical liquid treatment is the initial stage of water treatment before water enters the place of use and before further treatment of industrial wastewater.

With this method, no more than 60% of harmful substances are removed from the liquid and, of course, such a result cannot suit the final consumer.

Video: filter filter mechanical type “FM PRO”

How does water purify from mechanical impurities?

The whole process of mechanical water purification takes place in several stages:

- filtering fluid through;

- further sedimentation of water. When sedimentation of particles occurs, the density of which is greater than the density of water, as well as various oils and possible petroleum products;

- the next step uses large centrifuges or hydrocyclones. In these devices, under the influence of centrifugal force, water is separated from smaller particles that are collected in collections intended for them;

- the use of fine filters for water, in which sand, gravel, coal, cotton cloth can be used as a filter element.

Further, before being supplied to apartments and for production, water goes through several more stages of purification using biological or chemical preparations. Vodokanals use various devices for mechanical cleaning.

The most common of them are sand traps, oil traps, oil traps, grease traps. From the name of each of them you can guess its purpose.

Photo: oil trap  Photo: sand trap

Photo: sand trap  Photo: oil trap oil trap

Photo: oil trap oil trap

Filters

The mechanical filter consists of:

- special building - 1;

- cover - 2;

- holder or bracket - 3;

- filter - 4;

- nut pressing the filter to the housing - 5;

- a key for opening the case - 6;

- a sealing ring and a device for relieving excessive pressure - 7.

Photo: filter for mechanical treatment of water

Photo: filter for mechanical treatment of water Filters used for mechanical water purification can be divided into two groups:

- coarse filters;

- fine filters.

Each of them performs a specific function. The first group is able to save water only from the largest contaminants, and the second, more reliable, from the smallest particles. The difference between the filters is the use of different filter materials.

Video: how to replace a cartridge

Mechanical filter for fine water purification

The filters used for fine water purification are most common for residential applications.

They are able to filter out small particles of harmful substances and, without affecting the taste drinking water. Fine mechanical filters are divided into two groups:

Cartridge filters

Photo: cartridge filter

Photo: cartridge filter As a filter element are used, which are replaced. The mechanical water treatment cartridge is most often made of foamed propylene and, much less often, of steel mesh.

Photo: cartridge for mechanical treatment of water

Photo: cartridge for mechanical treatment of water No cartridge filter manufacturer will tell you exactly how long it will take to replace a removable filter. It depends on the quality of the water entering the residential or industrial premises.

You will have to change the cartridge when the filter user feels that the pressure of the tap water has become noticeably weaker. This is the first sign of severe contamination of the filter element.

To change the cartridge, you must turn off the water in the room, remove the removable filter and replace it.

The procedure is quite simple, does not take much time and brings a minimum of inconvenience associated with a short-term shutdown of water. Cartridges themselves are not expensive and you can purchase them in special stores.

Wash filters

They differ from the cartridge in that the removable filter element can not be replaced, but simply rinsed with water and put in its original place.

Photo: wash filter

Photo: wash filter Wash filters are divided into:

- mesh;

- mesh with backwash;

- disk.

The mesh washing filter for mechanical water treatment, like other washing filters, is similar in function to a cartridge one. The filter part is made of steel mesh, which is more reliable than propylene in properties.

To clean such a filter from accumulated contaminants, it is not necessary to remove and disassemble it. At the bottom of the filter there is a tap and drainage outlet connected to the sewers.

When the tap is opened, water enters the drainage and cleans most of the pollution accumulated during operation. The strainer for mechanical backwash water is cleaned differently.

Water, through the lower tap, flows in the opposite direction of filtration and thus washes away the accumulated particles of harmful substances.

Disk filters differ from other fine filters in that the filter surface is not a grid, but several disks. These discs are tightly interconnected and have grooves of various sizes.

Water passing through the accumulation of disks leaves all unnecessary impurities in the grooves and is thus cleaned.

Photo: disk filter

Photo: disk filter Flushing disc filters is easier than screen filters. During this procedure, the discs expand and release all accumulated particles of contamination.

Coarse mechanical filter

Coarse filters are similar to fine filters. They are similar in structure and function.

The difference lies in the fact that coarse filters are installed at the beginning of the purification system, and fine filters - immediately before drinking water. Rough cleaning is necessary when using heavily contaminated water.

Such filters trap the largest particles of impurities that can damage water pipes and other elements of the water system.

Coarse filters like filters designed for fine water purification are divided into groups:

- backwash;

- without rinsing (sump);

Photo: strainer

Photo: strainer  Photo: cartridge filter

Photo: cartridge filter  Photo: high-pressure filter

Photo: high-pressure filter The first two types have a larger mesh than the same fine filters, and therefore are considered coarse filters. Care must be taken of them in the same way as the filters described above.

The high-speed pressure filter is filled with filter materials. At the top there is a special automatic unit responsible for maintaining the quality of the filter and the entire filtering process.

Such filters have several disadvantages:

- require mandatory connection;

- they are very large;

- can work exclusively in heated rooms.

Installation

Installing a mechanical filter is not difficult. Both professionals and inexperienced people can cope with this task. First of all, you need to cook the tools.

This process will require:

- pipe cutter or hacksaw;

Photo: hacksaw pipe cutter

Photo: hacksaw pipe cutter - sealing material (FUM tape);

Photo: FUM tape

Photo: FUM tape  Photo: threading tool

Photo: threading tool - for plastic pipes - special fittings; for metal pipes - coupling and locknut;

Photo: fittings for metal pipes coupling lock nut

Photo: fittings for metal pipes coupling lock nut For installation:

- cut a piece of pipe just over the diameter of the filter cover;

- cut threads or fittings using FUM tape;

Photo: install filter

Photo: install filter Important! It is necessary to choose a place so that the bottom of the filter is at least 10 cm from the floor. Otherwise, it will be difficult to change the filter element.

If it is impossible to choose the best place to install the filter, then it is advisable to use flexible hoses.

In order for the filter to last for a long time, when installing it, it is necessary to take into account the water pressure. Some instruments are equipped with pressure sensors.

For others, these devices will have to be purchased separately. A properly installed filter, without the use of flexible hoses, looks like this:

Photo: installed filter without flexible hoses

Photo: installed filter without flexible hoses A filter installed with flexible hoses looks like this:

Photo: filter mounted with flexible hoses

Photo: filter mounted with flexible hoses Video: filter mounting

What is the difference between cleaning cold and hot water

Filters designed to treat hot water are very similar to cold water filters. The similarity lies in the principle of operation and types of devices, but there are fundamental differences.

At firstThe flasks of such filters should be made of high quality and heat-resistant materials. In modern industry, stainless steel or heat-resistant plastic is usually used for such purposes.

Secondly, filters for hot water should have a higher throughput and withstand strong pressure. It will be optimal if this indicator is at least 100 liters per 1 minute.

Thirdly, such devices should clean the contaminated liquid as reliably as possible. This is necessary to increase the durability of household appliances. Yes and take a shower clean hot water also very nice.

Prices

The cost of mechanical filters for water treatment depends on the type of filter, its purpose and manufacturer. Many companies offer a wide selection of these appliances.

The price range is quite large. You can’t say for sure that such and such a filter will cost so much, because, for example, Italian companies offer consumers filters at high prices, but they also give a great guarantee for quality and service.

Chinese filters are cheaper, but this does not mean that they are less reliable. Chinese manufacturers, as a rule, are limited only to the production of devices and do not engage in their maintenance.

We will deal with the average cost of specific types of filters in the Russian Federation.

| Type of filter | For which cleaning is applied | Price range, rub. |

| Cartridge | thin | 700 — 8000 |

| Cartridge | rude | 500 – 6000 |

| Flushing mesh | thin | 830 — 12400 |

| thin | 1000 -14000 | |

| Disk | thin | 1200 — 12500 |

| Mesh Backwash | rude | 900 — 10500 |

| Sump | rude | 350 — 2000 |

| High pressure head | rude | 1500 — 15500 |

To obtain high-quality drinking water, it is necessary to use filters for its purification, this has not been discussed for a long time, because the quality of the water supply in settlements, due to many aspects, is not sufficient to consider it completely safe and suitable for human consumption. Often there are cases when water can not only be consumed by humans, but is also not suitable for domestic needs and adversely affects the operation of household appliances (washing machines and dishwashers). Therefore, it is very important to use filters that can cope with all kinds of contaminants and can be installed both on pipes with cold water and with hot. These filters are trunk mechanical filterswhich help to cope with various types of pollution, are mounted directly to a water pipe and have the form of a flask. Thus, it is possible to ensure not only the consumption of clean and safe water by people, but also the opportunity to significantly protect household appliances and plumbing from the action of metals and impurities that cause corrosion. Even in the highest quality pipes and elements of technology. With their help, dirty and muddy water becomes truly pure and “alive”.

How to choose a main mechanical filter for water purification? In which online store to buy a mechanical water filter at the best price?

The choice of the main mechanical filter

When choosing a main filter, you need to pay attention to what type of water, hot or cold, they are suitable. The online store offers a fairly extensive selection of such filters, and qualified consultants help you determine the necessary parameters.

Due to the different size, the main water filter can have different throughputs, it also depends on the characteristics of the replaceable cartridge installed in the filter. A flask in combination with a polypropylene cartridge is excellent for mechanical water treatment. Such a filter is used to produce high-quality water in private homes or apartments, to ensure the protection of plumbing and household appliances from premature wear and breakage.

There are several types of cartridges used in main filters:

· Cartridge to combat mechanical impurities such as: sand, rust, clay, scale and other foreign matter.

· Cartridge with filter against chlorine and fluorine containing compounds, pesticides and nitrates containing granular carbon.

· The coal cartridge consisting of briquettes for additional cleaning of pathogenic bacteria.

· A cartridge softener filter that removes calcium and magnesium salts, affecting water hardness.

Depending on the degree of contamination and its type, main filters of several degrees from 1 to 3 levels for cleaning can be installed for cleaning running water.

The most popular are mechanical filters designed to protect the consumer from mechanical fractions and impurities. Using them, you can not worry about the water in your house containing clay, sand, rust or scale. Most often, these filters are made of 2 types of plastic: opaque and transparent using a cartridge of a special non-woven polypropylene, also called foam. This material allows you to prevent even the smallest fractions to the consumer. In apartments, the model most often used is a small one made of brass. It consists of: a body for mechanical cleaning, a special non-woven mesh made of stainless steel and a tap for forced washing.

To create cartridges that provide mechanical cleaning of water, the polypropylene used can also be mesh, corrugated or wound.

How does a main mechanical filter for water purification work?

Due to the fact that filters for hot water have to work in more difficult conditions, burdened by high temperatures, higher requirements are imposed on them, polypropylene has additional properties and is not amenable to the influence of temperatures above + 40 degrees.

When buying from an online store, you must remember that filters for different temperatures must be appropriate for the parameters, because when heating cold filters, their cleaning qualities are significantly reduced and the quality of cleaning decreases, as a result of which they quickly fail. Hot filters can be installed on cold water, but they are usually somewhat more expensive, and such economy is also very doubtful. Only with full compliance of the filters can high quality water for drinking and household needs be achieved. Only the acquisition of high-quality main filters will help in the future significantly reduce the costs of ensuring the uninterrupted operation of household appliances and communications and preserve the health of all households.

The acquisition of a main mechanical filter for water will be the key to professional high-quality water purification throughout the house.

Contact the AquaTime online store, we will select for you a main mechanical water filter with the properties that you need. You will buy the main mechanical filter for water at the best price in our online store!