Concrete rings volume m3. Concrete rings to create a septic tank

Concrete rings widely used for equipping wells designed for underground utilities. They are widely used due to ease of assembly and durability of the structure. In the private sector, concrete rings are used for the construction of septic tanks or wells. A fairly wide range of these products with standardized diameters is produced. However, in some cases, it makes sense to make them right on the spot, with your own hands. This article provides a concrete ring calculator.

This calculator will help to correctly calculate the required amount of reinforcing mesh and the volume of concrete mix per one product. A cubic meter of concrete made of cement grade M400 weighs about 2300-2500 kilograms. Having thus determined the approximate mass of one ring, a decision can be made on the lifting mechanism, which will be needed in the future for laying finished products during construction.

To use the calculator, click on the image below:

For independent manufacture of rings you will need the following materials and equipment:

- Components for the preparation of concrete mix:

- cement grade M400;

- sand of medium size with a particle size modulus of 2 - 2.5;

- crushed stone for construction, fractions 5x10 or 10x20;

- process water;

- Concrete mixer, for the preparation of high-quality mortar;

- Formwork or vibration form.

- Reinforcement mesh with mesh sizes 100x100 mm;

- Vibrator or vibration nozzle, for compaction of concrete after pouring the mold.

The concrete mix for making rings should be thick enough. The recommended ratio of components (cement - sand - crushed stone - water), in a ratio of 1-2-3-0.5, when calculated by volume. If the mixture is poured into the formwork without vibration, then every 20-25 cm it is necessary to ram the solution using a manual vibrator. After the mold is completely filled and the whole mixture is rammed in layers, the upper end is leveled and the finished product is covered with a plastic film. A film is necessary in order to avoid excessive drying out.

After 4-5 days, the ring can be freed from the formwork and proceed with pouring the next one. It is recommended to wrap the finished product with a film and let it settle for another 15-20 days, so that the concrete finally gains strength, while wetting with water every 4-5 days. All concrete work is preferably performed at a steady average air temperature of at least 10 ° C.

The effectiveness of using a septic well at the facility depends on two parameters - the volume of the well and waterproofing. So, in the construction of wells from reinforced concrete rings, the rings are fastened together with cement mortar, and sometimes are waterproofed from the side of contact with the soil. The effect of such adverse events for concrete as capillary suction can be reduced by using similar waterproofing and high-quality mortar grades not only at the joints, but also in the manufacture well rings.

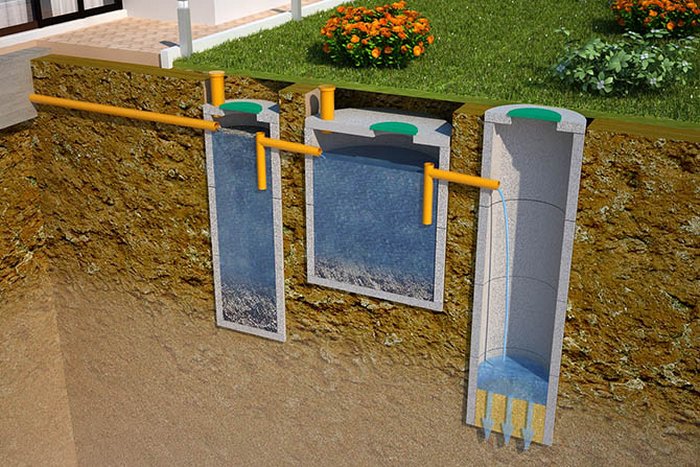

Let us consider in more detail the use of concrete rings in septic wells.

If we take the component of the need for the release of septic wells, then this issue must be approached thoroughly. It is known that the cylinder volume is calculated by the following formula

VOLUME \u003d 3.14 * DIAMETER 2 * HEIGHT / 4

That is, we have a nonlinear (quadratic) dependence on the internal radius of the considered well ring. For our ring height (900mm concrete ring) we obtain the following results for volumes of one ring:

0.7 m 0.3462 m 3

0.8m 0.4522 m 3

1,0m 0,7065 m 3

1.2m 1.0174 m 3

1,5m 1,5896 m 3

2.0m 2.826 m 3

For example, if you use three rings with a diameter of 0.8 on a well for a septic tank, the total volume will be

0.4522x3 \u003d 1.3565 m 3

With an effective volume of 2/3, we get 0.9043 m 3. It turns out that you will encounter the problem of calling the crawler machine “idle”. If you take a septic tank of 5 rings, then the total length of the required sleeve for a complete mass collection will be 4.5m + 2m \u003d 6.5m, if you cannot put such a machine close to the well.

The most common is to use reinforced concrete rings with a diameter of 1m. Few people know that if such a septic well is not cleaned at least once every 2 years, then solid residues can “seize” and then a jackhammer and crowbar will already be required to empty the well. Which, undoubtedly, will not be the most pleasant occupation. Even flushing with a standard sewer machine may not help (due to the insufficient water pressure of the equipment of such a vehicle) ...

On sunny hot days in central Russia, and in the suburbs in particular, the soil warms up approximately 0.8m down. Therefore, the upper ring is desirable to be always free (for the absence of unwanted fumes and the effect of "drying" of the upper layer). Additionally, an important task in the construction of a well from concrete rings is the tightness of the closure of such a well from above. For this top cover and luke you have to choose very carefully.

On sunny hot days in central Russia, and in the suburbs in particular, the soil warms up approximately 0.8m down. Therefore, the upper ring is desirable to be always free (for the absence of unwanted fumes and the effect of "drying" of the upper layer). Additionally, an important task in the construction of a well from concrete rings is the tightness of the closure of such a well from above. For this top cover and luke you have to choose very carefully.

For a quick and professional solution to the above, we offer you to use the services of the Three Rings company in the complex!

The use of concrete rings for the arrangement of septic tanks is an effective and practical solution for a simple and reliable system. Rings for a septic tank of concrete goods are convenient in operation, provide the optimum volume of a prefabricated structure. In addition, concrete rings for septic tanks are affordable, and the speed of installation will help minimize sewer costs.

Septic Tank Construction: Highlights of Choice

The construction based on concrete rings is round. By the type of its design, it can be single or multi-chamber. It is advisable to erect single-chamber septic tanks in the case of volume wastewater per day no more than 1m3. The number of rings for the structure of the sewage system is not more than 3-5 pcs.

Two-chamber sumps are constructed with a daily discharge of up to 10 m3. Three-chamber sumps guarantee a more thorough cleaning and are laid with daily waste volumes of more than 10 m3.

The constituent elements of septic tanks:

- The bottom or bottom plate ("PN") has a diameter corresponding to the cross section of the wall rings. The task of the bottom plate is to ensure an even, tight and solid foundation, necessary for servicing septic tanks and minimizing the subsidence of the entire structure on loose, floating soils.

- Wall rings for septic tanks ("KS") are called the working part, which is formed on the basis of elements of the additional, supporting or wall type. The number and size of products determines the calculation of design data.

- Overlap ("PP") - This is a floor slab made on the basis of the brand of wall rings. The covers are equipped with mounting loops, inspection holes, the diameter of which rarely exceeds 0.7 m.

- The neck is a structure formed by wall rings, the diameter of which is smaller than the main size of the structure.

- Hatch - it can be either polymer or concrete, cast iron.

Important! Starting the installation of concrete rings, it is necessary to check all products for chips, sagging, cracks, which can be either a manufacturing defect or arise as a result of improper transportation of elements.

- The height of the manhole is 1150 mm from the main elevation of the soil to the lower elevation of the floor slab;

- The highest edge of the hatch should not rise above the soil level by more than 0.8 m;

- Inside the septic tank rings, assembled into the structure, are coated with a solution based on cement and water enriched with calcium nitrate, and the dry plaster layer should not be more than 20 mm.

Important! Diameter of round single chamber settlers: 1000 mm, 1500 mm, 2000 mm. The height of the working part is 1.8-2.4 m. The calculation of the number of concrete rings is determined based on the diameter and height of the elements involved in arranging the sewage system.

Principles of calculating the volume of a septic tank

According to the regulations, the water consumption per person is 200 l / day. In order for the sewage system to run smoothly, we take the water consumption rate and the amount of effluent for 3 days, that is, for a family of 3 people, this is 1.8 m3. Arrangement of larger treatment plants will extend the life of the sewer.

Advice! An approximate calculation looks like this: using a ring with a diameter of 1 m, a height of 0.8 m and a standard volume of 0.63 m3 (volume of effluents less than 10 m3), a single-chamber structure of three concrete rings is being erected. In the case of the construction of a filtration well, it must be remembered that its volume should be at least 12 times higher than the daily water consumption, therefore it is recommended to use wider concrete rings in significant quantities.

Some tips:

- As a rule, reinforced concrete products of the 3.900-3 series are used for construction;

- A manhole (neck) is made up of rings for a wall septic tank, with a diameter of 0.7 m and a height of 0.29 mm;

- The use of a reinforced bearing ring to accommodate the hatch structure is shown to reinforce the upper part of the sump;

- For the distribution type wells agreed upon in the project, concrete elements of D1000 mm are used, collecting elements of D1500 mm.

Important! The use of rings with rebate locks prevents the possibility of horizontal displacement of the structure. The construction of multi-chamber sumps should be carried out on the same concrete basis, and it is better to assemble the entire system from single-chamber elements, connecting them through pipes.

The use of concrete rings: advantages, product labeling

For the installation of septic tanks, the use of concrete rings, floors, floors and hatches with high quality covers is shown. Manufacturers offer:

- Elements with ring and lock joints, and each product is equipped with protrusions and recesses, providing a stronger combination, preventing the displacement of the entire installation during operation;

- Concrete rings for sedimentation tanks straight without locks. Elements are joined, sealed by means of mixtures or sealants (inside and outside the shaft), and also fastened with metal brackets;

- A filtration ring for a septic tank is also offered - this is a type of concrete elements with perforation. The product has many holes located around the perimeter at an equal distance from each other, through which purified water enters the soil;

- Adjusting elements are designed to adjust the volume of the sump;

- Additional rings are shown to create the required height of the treatment plant.

The advantages of using rings:

- Price availability. Arrangement of a septic tank for sewerage for a summer residence will be cheaper compared to brick counterparts;

- Efficiency of installation, reduction of time spent on creating a system;

- Long term of operation (not less than 25 years);

- Physical accessibility, inspection, through the construction of brackets for descent, inspection openings.

Important! Using concrete rings to install a treatment plant system is a practical solution. Due to the large weight, the structures do not need to be anchored, they are less prone to deformation during soil movements, and if the sealing was carried out carefully, such a tank completely eliminates the ingress of untreated sewage into the soil.

Moreover, the dimensions of the structure can be any, since it is always possible to increase the structure by means of additional elements by choosing the correct diameter.

As for the varieties, sizes, the elements are of the following order:

| marking | KC10.9 | KC10.85 | KC15.9 | KS20.9 | KC7.9 | PP-10 | PP-10 | PP-15 | PP-15 |

| note | With a lock | With a lock | without lock | without lock | Without hatch | With polymer sunroof | Without hatch | With polymer sunroof | |

| Inner D (mm) | 1000 | 1500 | 2000 | 700 | Outdoor D1200 | Outer D 1200 | Outer D 1700 | Outer D 1700 | |

| Height (mm) | 900 | 900 | 900 | 900 | 130 | 130 | 140 | 150 | |

| Thickness | 80 | 90 | 90 | 70 | — | — | — | — | |

| Weight, kg) | 550 | 850 | 1350 | 360 | 200 | 240 | 600 | 680 |

Thus, knowing the main characteristics, the volume of the rings, it is possible to calculate costs, take into account the dimensions that the sewage system for a summer house or home can have, and also estimate the total amount of work. When using special equipment, it is better to choose the lower structural element with the bottom, in order to ensure more efficient tightness of the entire septic tank.

Sewage treatment and sewerage rules

After the calculation of volume, height and dimensions are taken into account, the sump is collected and the whole system works as follows: water enters the purification chambers, where organic compounds are already rotting and the liquid is clarified by beneficial bacteria. After the flows are sent through pipes to the distribution and filtration device. Then the streams cleared of mud inclusions seep into the ground or diverted to natural water intake tanks.

A fully finished sewage treatment plant must be regularly inspected and preventive measures taken. In particular:

- clean the inside of the shaft from crusts twice a year (spring-autumn);

- to prevent the sediment and crusts from rising to the uppermost technological openings, through which flows are poured into the cleaning chambers;

- so that the cleaning takes place as thoroughly as possible, it is better to stop the flow of water before cleaning measures, and clean the deposits by means of forks or scoops (the residues are pumped out with a cesspool machine);

- to renew and repair rings, bottoms.

Despite the simplicity and strength of structures, it is necessary to observe safety measures: ventilate the sump before starting work, take a rope and a lamp into the shaft. Depending on the volume of the structure, the calculation of the frequency of treatment measures is performed. In particular, for a cottage equipped with a small number of plumbing fixtures, cleaning can be done no more than 1-2 times a year, and for a country house of comfortable living, the procedure is carried out as necessary, up to 6-8 times a year.

Important! If it is not possible to establish the volume of water consumption, the quantity of wastewater is taken into account not for 3 days, but for a longer period. In this case, the calculation of the capacity of the tank increases by 15-20%. In this case, the user can be sure that the sewage system will work flawlessly in both standard and peak modes.