Do-it-yourself decorative house for the well. Roof for the well with your own hands.

Greetings to all readers! The functionality of the house for the well is obvious - it will protect children, protect water and pumping equipment from pollution and ultraviolet radiation, heating in heat and freezing in winter. If the house is made with imagination or stylized for other courtyard buildings, it will harmoniously complement the landscape of the site and even be able to become one of the visual centers.

Tools and materials

Houses for wells are traditionally built of wood. Therefore, during the construction we will need:

- Roulette, pencil, construction level, electric planer, jigsaw;

- electric drill with crowns for wood, grinder;

- hammer, hacksaw, Phillips screwdriver or screwdriver;

- fasteners (screws, staples, nails), door hardware (hinges, handle, latch);

- roofing material, lumber (timber, edged board), rolled waterproofing material.

Preparatory stage

Before you begin construction, develop a project and prepare drawings. If there is no possibility or desire to independently come up with an original design, a suitable sample of the house can be found on the Internet. Be careful when choosing, the open-type house is a canopy over the well, it is less functional.

With all the difference in the visual appearance of houses for wells, they are built according to one principle:

- the ground part is being constructed (around the upper ring of the well, a quadrangular, multifaceted or round structure of logs, timber, stone, corrugated board or other materials is mounted);

- racks for the gate are installed (in order not to depend on the power supply for pumping equipment, it is useful to provide a design for mechanically lifting water from a well);

- mounted rafter system for a pitched roof (usually gable or multi-faceted);

- a door is installed at the house of a closed type.

Please note: if you plan to install a gate with a handle or a steering wheel, the door of the house is installed on one of the ramps. If the well is not supposed to be equipped with devices for manual lifting of water, and the house is needed to protect the pumping equipment, the door can be installed on the front side - this will provide convenient access to the equipment for inspection and maintenance.

The dimensions of the house are selected individually and depend on the type of construction. In order for the roof to withstand wind loads and not accumulate snow, it is better to choose a slope angle of about 60 degrees. Based on these parameters and the dimensions of the well base, the height of the support posts is calculated. Next, we will consider how to build a house for a closed well with a base of timber and a gable roof.

Building a house

Around the upper concrete ring of the well, a concrete platform is usually arranged or tiles are laid so that there is no constant dirt from spilled water. On this basis, you can erect a wooden blockhouse, laying under it two or three layers of waterproofing material.

Please note: after cutting to size and fitting the wooden elements, they should be doubled (with a break for drying) treated with an antiseptic compound to prevent rotting of the wood.

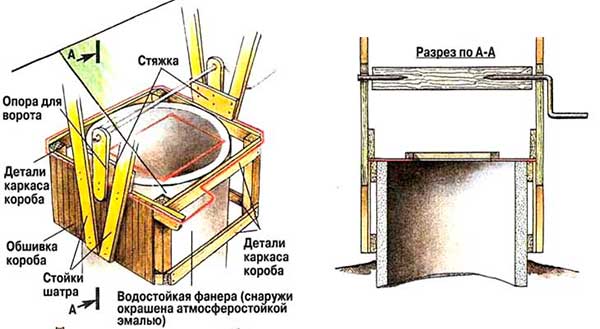

Base. The timber structure, which covers the outside of the well from the sides and serves as the basis for the roof, consists of a frame and casing. The frame requires 4 vertical posts and 8 horizontal elements, which make up the upper and lower crates.

The frame is lined with the same beam, but you can use suitable sheet materials for exterior decoration. The base frame begins with the installation of the lower battens and fastening the racks. Then the upper crate is installed: its upper edge should be at the same level with the edge of the well ring - this should be taken into account when calculating and preparing the drawings. Be sure to check the horizontal and vertical planes of the structure. When sheathing the frame, make sure that the corners are even, and there are minimal gaps between the bars - this will prevent the skin from being deformed when the wood expands due to moisture and high temperature.

Racks and gates. Racks are made of a thick board (50 mm) or a bar 10x10 or more (depending on the dimensions of the gate itself) and are attached to the upper crate of the base. If the roof and the gate are massive, then the racks are best done long and attached to the sides of the base.

A gate requires a piece of log with a diameter of 200 mm or more. The surface is cleaned of bark, skinned. Holders cut into the ends (holes for them with a diameter of 20 mm and a depth of 50 mm are required to be made under them), metal bushings are inserted into the racks. Carefully take measurements to set the gate horizontally. In the upper part of the rack they are connected by a thick board located edge up - it will serve as a ridge of the roof.

Roof. The supporting frame of the structure is mounted on the upper trim of the base. Dimensions are selected so that the lower edge of the roof slope is 15-20 cm from the base, protecting it from precipitation. The corners of the frame are connected to the ridge board by racks of timber, the edges of which are sawn at the necessary angle. To strengthen the system, you can additionally fix the struts with slopes. The crate is packed on the racks - solid or sparse, depending on the roofing material chosen.

Door and roof sheathing. The door itself can be made of boards and transverse bars. Do not forget to mount the frame under the door when assembling the roof frame. The front part of the roof is sheathed with boards or timber, waterproofing is installed on the slopes, a counter-lattice and a suitable roofing material, resistant to mechanical stresses, so that the finish does not suffer when the door is constantly opened. The door can be finished with the same material.

Final stage - installation of wind boards so that the wind does not tear off the skin of the house.

Video on the topic "do-it-yourself house for a well":

What could be better than cold and refreshing well water on a hot summer day! Especially if in the private sector it is often the only source of water for both drinking and household needs. But it is worth noting that just building a good well is not enough, you need to protect it from getting insects, dust, etc. For this, we will build a house for the well with our own hands. A step-by-step process instruction will be presented in this article.

General information

If we list the engineering structures of antiquity, then the well will be on this list. Currently, the design has been greatly improved. People added interior wall treatments and exterior finishes. All this made it possible to make the well not only more durable, but also attractive on

But it happened when birds, animals and even small children fell into the wells. In most cases, this led to the fact that prolonged exposure to cold water quickly leads to hypothermia and, as a result, death. It is for this simple reason that they came up with protective equipment that covers the well when it is not in use. The first designs were elementary. Now the most popular are small houses, the so-called tents. This design not only provides reliable protection, but also performs an aesthetic role. Let's talk about how to do it yourself. Step-by-step instructions in this case will be very useful. We will start from the very beginning.

About materials and tools

Before proceeding directly to the installation work, it is necessary to prepare. For work, we need certain material. As noted above, we have a lot of options, but the most attractive and simple is a small wooden house. Make it easy enough. For this we need a wooden beam 50x100, and lining. As a material for the roof, a roofing material is suitable. As for consumables, then here you need to properly prepare. Buy screws, staples, angles, nails in advance.

We don’t work without a tool, so be sure to take a screwdriver. Of course, you can not use it, but then the work will be more time-consuming and complex. You need to have at hand and a planer, as well as a jigsaw, preferably electric. To all this we add a hacksaw, and we are fully equipped to begin construction work.

How to make a house for a well

As a material, tile, stone, concrete, brick, etc. can be used. In general, it all depends on preferences, but it is necessary to work with this or that material in different ways. After you find the tool and material, it is advisable to develop a conceptual design, even if it’s small and unpretentious. On it you will indicate all the details, such as the dimensions of the house and its design features.

At the next stage, preparatory work is performed. The area near the well must be well removed so as not to do this after the construction of the house. Yes, and during construction, excess elements can interfere underfoot.

Then you can make a foundation. For this, stone or tile is perfect. The fact is that if a beam is used as the basis, then, being in the ground, it will undergo decay, therefore, the house will turn out to be short-lived. But the stone is what you need, it is durable and reliable. Since it is not difficult to make a house for a well alone with your own hands, you will do without an assistant. Getting to work.

Assembling the frame

The frame is the foundation of our house. It should be simple, but at the same time very durable and reliable. As a material we will use a beam and a trim board. In general, we need 4 racks 50 cm high and trim boards for strapping. The structure is fastened using nails. For reliable joints, use nails with a length of at least 10 centimeters.

The assembly process begins with the preparation of two racks. Above and below they are connected by edged boards. Next, two halves of the structure are installed around the well and are connected by a strapping. To build a house for a well using this frame is the easiest. The fact is that in our case a very running material is used, and the design itself is very simple and universal.

We are engaged in a roof

So we already build our house for the well with our own hands. A step-by-step instruction involves a strict sequence of actions that must be followed to achieve the desired result. The frame is, of course, good, but by itself it does not provide protection against the ingress of various elements into the well. The roof is what we really need. There is nothing complicated here, but it is advisable to adhere to the dimensions indicated on the drawing. All elements of the lathing should be done clearly and with equal steps.

To begin with, you need to do it. It is desirable to arrange it in the form of a rigid structure, on which the crate is nailed. Of course, rafters should be made using materials such as crossbars (3 pieces), jibs from a thin board (8 pieces), rafter elements. The rafters need to be beaten so that there is an equal distance between them, so you get a reliable and durable house on the well. It is advisable to use the drawing for best results.

About roof assembly

As noted above, we can well do without an assistant, that is, on our own. In this case, the assembly of the roof is preferably carried out on the ground. In addition, it is important to observe the following sequence:

In general, the most difficult stages of work have been completed. It remains to fix the roofing material on the roof, and on top of it - slate. Corner joints should also be closed. For this, wind boards are suitable. Here is a house for almost ready, there are a few more touches.

We make the door

In general, this stage is not necessary, since the hole where the door should be can be closed with a piece of slate or something like that. But this approach is not very convenient, therefore it is better to spend a little time once, and enjoy the result in the future. The door can be made in the form of a wooden board. This is a simple, but at the same time reliable design.

As the main material we use a trim board, suitable in size for the pediment. We fasten the structure with the help of a bar, for this, nails of the appropriate length are suitable. Only 2 bars are needed. One is attached on top of the shield, the second on the bottom. If the strength is insufficient, then you can diagonally fasten an additional block. If you wish, you can attach a pen, and if necessary add a lock. Something like this is the production of houses for wells. Now let's move on to the final stage.

Beautiful houses for wells: what is the secret?

After you do everything, look at what happened. Agree, everything is slightly different than in the picture. The thing is that finishing work is necessary. Sometimes this is completely unnecessary, but if there is time and desire, then why not. The board can first be sanded, coated with a special varnish and painted on top, say, in black. On the racks you can add thread, which will give the design a more attractive appearance. But do not forget that the main purpose of such a house is the safety and protection of water from pollutants. Therefore, the door must close tightly. In general, the finish can be what you want. This is just the case when you can give free rein to your imagination.

Conclusion

Basically, now you know how to make a house for a well with your own hands. Step-by-step instructions will be a great helper for you. I would like to note that there should not be any difficulties in the process, but you need to take into account the fact that the house for the well, the dimensions of which you will have in the drawing, can be built on problem soil. Prepare a simple drawing, believe me, it will help you a lot. It is advisable to carry out all the work in the warm season, especially if there is a concrete base in the plans, since it requires warm and not wet weather to solidify. In general, the complexity of the design, as well as its appearance, completely depends on your goals and capabilities. If you have the time and money, then you can experiment and come up with something really unique and amazing.

In a completely modern landscaped cottage or manor, the presence of a water supply system is not a reason to abandon your own well. It is even more important to arrange it according to all the rules, if this is the main source of water in the countryside.

We will explain why it cannot be kept open and how to protect it. Inspired by the considered projects, you can quickly make a house on the well out of improvised materials or have patience and realize your own exclusive project - original, high-quality, most practical.

Well house

In this article, we will consider various aspects of the construction of a house above a well:

Typical or original designs.

Constructive and finishing materials.

Issues of stylistic unity with the landscape and suburban architecture.

Practical side

A well is a source of the purest drinking water, but if it is not protected from precipitation and other pollution, it will become tasteless or even hazardous to health.

Simply attaching a door to the log house is clearly not enough - rain and thawed snow will penetrate through the decaying boards. To prevent this from happening, it is customary to build a special structure, the so-called house above the well. It protects against atmospheric precipitation, fall foliage, floods, foreign objects, insects, etc. And in the northern regions - and from freezing.

The house protects the well from debris

Do you need a roof?

Indeed, why this headache, is it really not enough just to cover the well log house (or concrete ring) with a door or even leave it open?

To begin with, we recall terrible stories about how someone's baby fell into the well - and that's all, this alone is enough to try to make the structure as safe as possible.

The house will make the well safe

The second unpleasant moment - theoretically small animals, rodents can fall into it. There is no need to talk about water quality in this situation. Moreover, for a long, long time no one wants to use it - well, perhaps, for watering.

Thirdly, insects inevitably fall into the open well, it is carried by fallen leaves, sweeping with dust. As a result, the water soups, the bottom silts up, the flow of fresh water slows down, the well becomes shallow. The bottom will need cleaning, and only experienced enough people will cope with such work.

The house eliminates the need to clean the bottom of the well

A good shelter keeps cool in the heat, and in winter protects against freezing. And finally, a well-designed well, it is so romantic and beautiful! On small architectural forms it is more convenient to hone building skills and not limit oneself in imagination. Perhaps that is why the design of houses for the well often turn out to be original and bright.

Building materials - cheap or expensive?

It is unlikely that deciding to build a house over the well with his own hands, the owner sets out to use the most expensive materials. If he is not limited in means, then he will most likely choose durable, expressive, suitable to the style of the estate. We attribute to them:

- calibrated timber;

Lodge for a well from a bar

- a natural stone;

House for a well from a stone

- facing brick;

Brick house for a well

- lining and profile wood paneling;

Clad lining for a well

- shingles.

Tiled roof well

Oddly enough, many materials that are usually classified as prestigious will cost the builder inexpensively. The secret is that you can use the building materials left over from the construction of the estate - this, by the way, will help in maintaining a unified style of buildings. On the other hand, a well house is a miniature structure, and if you have to purchase exclusive materials on purpose, small volumes are not so expensive as to deny yourself the idea.

Well house in harmony with the general style of the site

The opposite approach is also quite relevant, when it is necessary to meet a limited budget. Cheap building materials can look very impressive if they are successfully selected for a particular project, for example, in the spirit of rustics, provence, scandy. Sometimes they cost nothing at all, but require a builder of a certain ingenuity, skills, sense of style.

Provence-style well house

It can be:

- reiki

- timber;

- slate;

- pebbles;

- flagstone;

- metal profile trimming, etc.

Forging is definitely expensive forging. Forged elements are capable of carrying a power load, of which graceful and durable racks, rafters, door fittings are performed. Such constructions are incredibly beautiful and are custom-made, although what crafts can an craftsman possessed by an interesting idea not be able to master.

Cabin for a well from improvised materials

Typical well house designs

Any house on the well can be attributed to a closed or open type. Open type structural elements:

- The aboveground part of the log house.

- Racks for the lifting mechanism.

- Roof with rafter system.

- Cover and door on the log house.

Open wells are traditional for villages, they are especially convenient if several owners use them. There were certain rules for their design. Craftsmen decorate them with carvings, figured visors.

Open well

The design of the closed type is fundamentally different from the open one by the presence of external walls and includes:

- The aboveground part of the log house.

- Racks with a lifting mechanism (collar).

- The walls and the door are locked.

- Rafters and roof.

However, outwardly such wells turn out to be very different from each other. Walls in closed buildings can be integral with the log house, or roof slopes play their role, but in any case, such a house on the well protects it from the weather, the curiosity of children or animals, and vandalism.

Closed well

Often, instead of a bucket, a pump is used on the lifting mechanism - in this case, a closed house prevents the theft of electrical equipment.

Foundation preparation

Before starting the construction of the house above the well, it is necessary to ensure the outflow of rain and melt water, and for this - fill the voids around the upper concrete ring, raise the soil and protect it from erosion and penetration of water.

The simplest thing is to concrete the slopes. This is not particularly aesthetically pleasing, but it fulfills its function - it protects the well from the ingress of unfiltered water through the soil. In addition, the concreted base becomes a reliable foundation for the entire structure.

If the slopes are not framed before the start of construction, then they can be done at the end of it, but in this case the entire construction of the house will be based on concrete rings.

Concrete well base

To improve the area around the log house, it is paved with pebbles, cobblestones, flagstone, concrete or ceramic tiles. Or arrange wooden blind areas and steps. Do this after the construction of the house on the well.

Arrangement of the site near the well

The mowed lawn around the well looks beautiful - in this case, a layer of soil is poured on top of the concrete base, rammed and sowed. It is necessary to provide a non-slip path to the house.

Facing the aerial part of the log house

What we habitually call a log house, in fact, has long been made of concrete rings. The upper ring protrudes from the ground and looks unpresentable. It is especially important to veneer it when an open-type well is being built, since in closed ones the ring can be hidden behind the walls of the house. But even in closed structures, the successful design of a log house can give completeness to the entire structure.

Wooden traditions

To give the house over the well a purely rustic look, a log house is laid around the concrete ring. It is not necessary to adhere to the traditional square shape - the blockhouse is made both hexagonal and octagonal. It is brought out above the level of the rings and closed with a wooden flooring, in which a hole with a door is cut for a bucket.

Log cabin for a well

For a Russian-style estate, a log house made of round logs is the most suitable option. If the traditions of Scandinavia are traced in the buildings, then a rectangular beam or cladding lining will be acceptable.

Lining of a well lining

Masonry - a journey to the land of elves

European color carries a well with masonry. It will look fabulous on a site with a small wooden house and a garden in the spirit of Provence or next to an English-style brick cottage.

It is not difficult to stone the concrete ring, for this you will need diligence, cement mortar and the stone itself. You can use large cobblestones, pebbles, flagstone, and flagstone looks especially picturesque if laid flat. Along with stone, facing bricks and tiles imitating natural masonry are used.

Masonry in the design of the well

In open wells, it is necessary to cover the upper edge of the ring and fix a wooden or metal cover (door) on it.

Metal, but not plastic

There is nothing that prevents the use of unconventional materials in the design of the upper part of the log house, from the metal profile to plastic. And if plastic could be immediately rejected, as the material is short-lived, not able to withstand low temperatures, then metal sheets can lead to interesting ideas. Of course, under such a lining it will be necessary to erect a wooden frame.

Facing the well with metal

Racks and rafters in the house for an open type well

In closed wells, racks are hidden behind the cladding, but in open wells, racks and rafters play a leading role in design.

Wooden racks are decorated with sculpted and slotted carvings, or left “as is”, admiring the game of texture. The tree must be treated with compounds from decay and varnished to protect against the effects of rain. If the base of the house on the well is finished “under a stone”, then next to it stands stand from a dark, as if aged tree.

Well stands

Racks must be strong, they must be well secured. They have to withstand not only the weight of the roof, gates and buckets of water, but also the load from the rotation of the gate in jerks. Therefore, supports made of metal pipes or concrete are an excellent solution, especially for a stone well or a closed house.

Metal well stands

Lifting mechanisms - gate and wheel

It would seem that nothing can change in the design of the gate, however, the interpenetration of cultures here can bring surprises. One of the discoveries presented to us by Provence was the wheel. A wooden (or, more rarely, forged) wheel is attached to the shaft instead of the usual gate handle.

Types of lifting mechanisms for a well

In fairness, it should be noted that usually the bucket is still raised with a collar, and the wheel is installed on the other side of the shaft - for beauty and a kind of surroundings. Such a construction looks very picturesque, especially if the aboveground part of the log house is lined with stone.

Well lifting gear

More often, an electric pump is installed in the well, and everything else is nothing more than a tribute to tradition.

The roof is the crown of creation

The mechanical load on the roof with an area of \u200b\u200b2-4 m2 is insignificant, and therefore nothing limits the imagination of the craftsmen at the final stage of the construction of a house for a well.

An absolutely fabulous tiled or thatched roof crowning a house on a well with masonry elements will not take much effort during construction, but will turn an ordinary household object into an estate decoration.

Thatched roof well

In order to emphasize the Russian style, the roof of the house above the well can be made a plank. The roof of wooden tiles looks especially interesting.

Roof for a well with wooden tiles

If the frame is built of metal or concrete, a metal roof will be appropriate. However, on wooden wells this practical material is used very often.

Closed Well - Functionality and Design

Everything mentioned above is also true for closed wells, excluding special requirements for the design of racks and rafters, which are hidden behind walls in closed houses. We’ll talk about walls especially.

Actually, the walls of the house are designed to perform a certain function - to protect water from pollution as much as possible, protect equipment, including pumping equipment, from theft and prevent the well from freezing during harsh winters.

Closed house for a well

As a rule, during the construction of a closed house with their own hands, the walls are made of wooden slats, lining, facing wooden profile - according to the prepared frame. And this is true for wells with wooden and stone log houses. By the way, the special design of the log house in this case is not necessary, it can be hidden behind the walls.

A house for a well with a metal tile

The minimalistic design “hut” stands out in which the roof plays the role of two walls, usually from a profiled metal sheet, and the other two are made from the material of the log house. It is difficult to call such structures an architectural masterpiece, but they perform their service properly.

Standard well house design

On the well in the wall of the house they make a rather large door that locks - a bucket full of water should freely pass into it.

Do it yourself, by your own rules

The most difficult part in constructing a well is to dig it out and install concrete rings. And most of those who have at least some construction experience will cope with the construction of the house over the well. We hope that you will be inspired by these photos of houses above the well, our comments and tips.

Photo gallery - a house for a well

![]()

![]()

![]()

Whoever drank well water at least once understands why many summer residents try to build a well on their site. Crystal clear, icy, “living” water perfectly quenches thirst. In addition, the well is a symbol of village life and everything connected with it. To ensure that clear water is always clean and ready to use, the well head must be covered, protected from dry branches, leaves and grass, insects and dust - all that is carried through the air. The role of the mud barrier will be perfectly played by a beautiful and compact house for a well, which will fulfill two important functions:

- practical - will protect a well log house or reinforced concrete rings;

- aesthetic - decorate a suburban area with an unusual design.

Installation of a carved house for a well: step-by-step video

How to make a house for a well on your own

There are two ways to equip this building:

- It is possible to order a house in a company that is professionally engaged in construction. An engineer or foreman will advise on all issues, create a project, calculate the cost - and at this stage you will realize that even any miniature model will be quite expensive.

- The second way is to design and build a house for the well with your own hands, investing in it a piece of your soul and skill. It will be much cheaper, it will bring a feeling of satisfaction, but it may take a little time - in case you plan to create a real masterpiece.

Of course, craftsmen and simply zealous owners will like the second option: you can equip a well and engage yourself in creative work. And how nice it will be to see every day near the house this original and useful building, created completely independently!

Roof house performs the main function - protects well water

A variant of the elementary design scheme

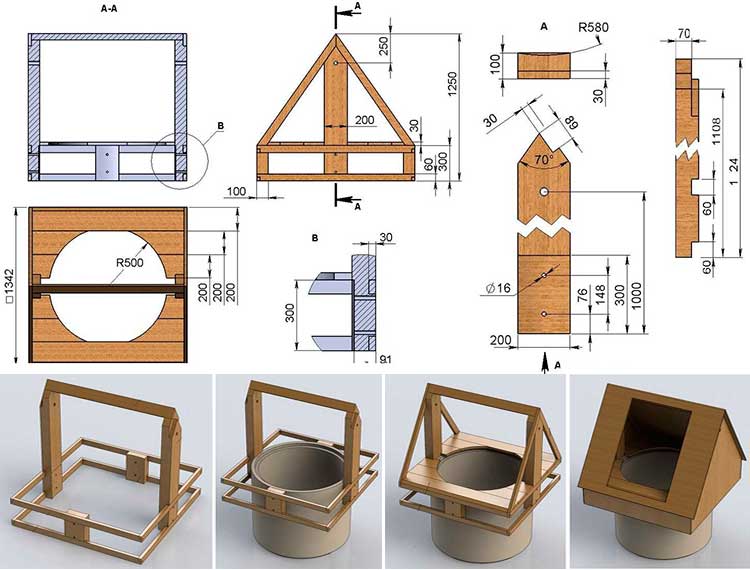

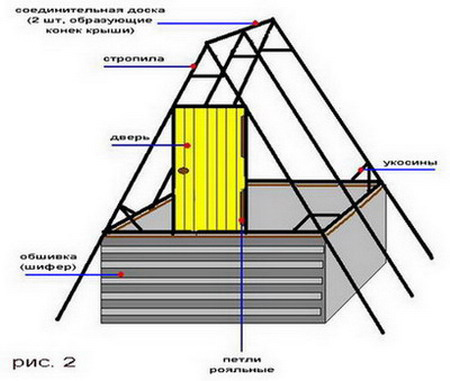

Here is one of the simple options available for self-construction. Even a person who is far from carpentry, will be able to construct this elementary house for a well: the drawing shows well what parts are needed for assembly, and how they are interconnected. The material for the manufacture is wood, although the roof can be covered with slate or polycarbonate.

The main parts of the structure:

- The basis of the timber (1 pc.)

- Pediment (2 pcs.)

- Connecting stand (2 pcs.)

- Roofing horse (1 pc.)

- Gate (1 pc.)

- Gable trim (2 pcs.)

- Rear roof slope (1 pc.)

- Front roof slope (1 pc.)

Tools and materials for creating a house

You are lucky if the construction of a country house has recently been completed or is still ongoing. In this case, not only the necessary tools, but also various materials for equipping the well mini-house will be at hand.

List of materials that ideally should be available at the very beginning of construction:

- edged board;

- log (future gate);

- wooden beam (50x50 mm, 50x100 mm);

- wooden lining;

- a thick rod of metal (preferably steel);

- stainless steel corners;

- bushings;

- covering materials (slate, tile, polycarbonate, roofing material);

- a bucket with a chain;

- nails, screws;

- door handle and hinges;

- compounds for wood processing: stain, antiseptic, paint.

Minimum tools for processing materials:

- plane;

- circular saw (if any - a machine);

- jigsaw;

- hammer;

- hacksaw;

- screwdriver;

- building level;

- roulette;

- pencil.

When all the tools are within reach, the job argues faster and takes less time to search.

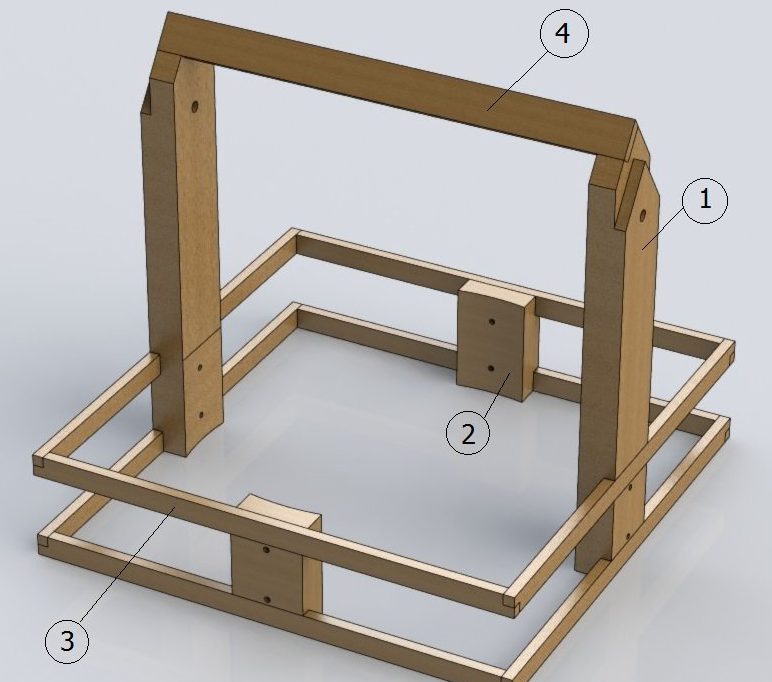

Frame construction

To begin with, you should accurately determine the outer diameter of the well, if it is round, or the width if it is square. The resulting number is the distance between the opposite sides of the future frame. Having specified the dimensions, we assemble a frame from a beam of 50x100 mm. During construction, it is necessary to use a level so that all parts lie flat and there are no distortions.

The construction of the frame resembles the erection of the roof of the house, but in miniature

Next, we fix on the base two racks from a similar beam. It is important to immediately determine the size of the racks - it is of this height that the well house will be. Metal corners will help to tightly fix the joints of the racks and the frame.

We take a beam of 50x50 mm and prepare rafters from it. To install them, the ends of the frame and rack parts must be cut at an angle of 45 °. In the place where the door installation is planned, a wide board should be nailed, which will serve as a stand for the bucket. We equip the other three sides with narrower boards. They are needed to fix the structure on the well rings, so their width should be sufficient.

Gate device

Even if the well is equipped with an automated system with a pump, a gate is needed to raise a bucket of water. Without this detail, any well looks unfinished.

We need a straight log, the diameter of which should not be less than 20 cm. Having previously removed the bark, knots, having prepared and skinning it, cut it so that its length is slightly less than the distance between the uprights, by about 4 cm. Clearances of 2 cm guarantee easy rolling gate while raising a bucket of water. So that the shape does not change, you can strengthen the log with a solid wire.

The gate must withstand loads of up to 12 kg, so the log for its manufacture must be strong

On both sides at the end of the gate you need to drill holes with a depth of 50 mm and a diameter of 20 mm. For protection and strength, we use metal plates, fixing them over the holes. Similar holes with plates will be in the racks - opposite the first. In addition, bushings should be inserted into the openings of the uprights so that the collar does not touch the uprights while scrolling.

To install the gate between the racks, you will need two rods driven into the prepared holes. On the left we insert a small rod 20 cm long, on the right - a large rod 100 cm long. The meter rod should first be bent in the form of a zigzag - this will be a rotary handle.

The final stage is fixing the chain to the shaft with a bucket at the end.

Door and paneling

It’s easy to build a door. First, we make the frame, fixing four bars on the frame: two parallel to the rafters and two horizontal. On the frame should be laid down sawn-in-size boards, fastened together by small bars. The third bar is useful for structural rigidity: it is pinned to two diagonal connecting elements. The result is a door that looks like a shield.

A house with carvings will delight your eye

We fix the piano loops on the frame of the building and hang the door made on them.

The next stage is the lining of the house with a edged board, which can be replaced with a clapboard or blockhouse. The blockhouse also serves for decoration and is a board, on the one hand, similar to a rounded log. If you think that the roof of the house is not sufficiently protected, use improvised roofing material. Roofing material, shingles, slate, etc. are perfect.

The remaining parts of the house can be ennobled using stains, primers or special decorative compositions, such as paint or wood glaze.

Traditional and original solutions

If you decide to independently design a house for a well - photos of various models can be found on the Internet or in landscape design magazines.

The house for the well can be painted in the same colors as the large house

It is unlikely that someone will pass by a miracle house, decorated on all sides with delicate carvings. In addition, this structure is painted using two matching colors - black and woody yellow. A noticeable contrast gives the house a shade of nobility. As you can see, the roof is simply wooden, without additional coatings.

If you like the naturalness of wood, you can focus on a rustic-style model - deliberately rude, but quite colorful. Standing a log house made of logs will perfectly complement a house built using the same technology. The naturalness of the material is maintained through the use of a protective transparent varnish.

Before varnishing, wood should be treated with antiseptics

If the family has children, then they will definitely like the house in every sense of the word. It seems that a small gnome settled on the site, who built a neat little tower for himself. This model will last a long time, since the walls are treated with stain and protective varnish, and the roof has an additional coating.

The original house looks great, both in a small garden and on the banks of the pond

This structure resembles a mushroom with a large hat. The roof of the decorated boards is installed on a solid foundation using natural stone.

You can take a chance and lay out the foundation with porcelain stoneware or tiles - then you get a completely modern structure

Now you know how to build a house for a well. Of course, do not dwell on the models you saw - thanks to personal imagination and skill, you can create a unique structure to protect the well. The house may resemble a bee hive, a hut of Baba Yaga or a mill, in any case it will be one of the best decorations of your summer cottage.

Not everyone has the opportunity and desire to build such a structure with their own hands, so you can always buy a finished house. Most often, they are sold disassembled, which facilitates delivery to meta. It is at the installation site that the assembly is carried out according to the instructions - the assembly process is no different from playing a children's designer, even a child will cope with it. However, it should be borne in mind that finished designs have fairly high prices. They depend on the material, design, size. Therefore, if you do not have extra money, then it is better to build a house yourself.

What materials may be needed?

As a rule, in the construction of a house for a well, the following materials are required:

- timber, cylindrical logs;

- wooden boards;

- siding panels (or slate);

- ondulin;

- ceramic or concrete tile;

- natural or artificial stone;

- metal tile;

- connecting and fastening elements;

- other building materials.

When choosing material, remember about the already built and decorated objects of your land. Their color scheme and style should be in harmony. Usually, materials that remain superfluous during the construction of a house or a fence go to the construction of a well house. The area around the well is strewn with rubble.

Timber and other wood material requires special equipment for processing:

- electric jigsaw;

- saw, hacksaw;

- hammer or sledgehammer;

- nail clipper;

- phillips screwdrivers of various sizes (drill, dowels);

- roulette;

- shovel.

Drawing of the simplest configuration

Make and issue the simplest drawing of the desired design or refer to the construction literature and use blanks. It is easier and more convenient to engage in construction on them.

1.Rama; 2. gables; 3.stand; 4. skate for the roof; 5. gate; 6. sheathing of gables; 7. left roof slope; 8. right roof slope.

The construction of the frame and the roof of the house work stages

First of all, it is necessary to measure the outer and inner rings of the well.

Then from the timber section of about 100 to 80 mm, the base of the house is collected. Remember that the distance between the parallel sides should be approximately equal to the outer diameter of the ring.

The racks are connected with logs or scraps of section 50 to 50. For the corners of the base, special incisions are made. Reinforced bars serve as rafters.

![]()

A spindle for lifting water from a well is made from a bar, the size of which must be taken into account. It should be 3-5 centimeters shorter than the distance between the uprights.

Exactly in the center of the ends, holes are drilled, the diameter of which can be selected in the range of 1-3 centimeters, and the depth is about 5 cm.

Then, metal plates are installed on the ends of the holes on top of the holes, in which exactly the same holes should already be made. The plates are fastened with self-tapping screws.

A metal rod is inserted into the left part of the spindle, the length of which should not exceed 9 centimeters, and its end - 4 centimeters outward.

The right side of the gate is designed with a manual starter.

In a well-thought-out place in the racks, special holes are made for the bushings. They wind up the end of the gate. The bushings are lubricated with grease or other grease.

At the end of the work, a chain with a bucket is fixed on the collar.

Upstairs, boards are installed that serve as a skate for the roof. Make a crate.

Finally, the work ends with a slate, ruberoid or metal tile flooring.

Decoration of a well house

The standard design of the well house provides for a door, the size of which should be approximately equal to 850 by 550 mm. They knock down the door from the remains of working with a well or other constructions of a summer cottage, knocking it down from boards connected by 3-4 bars. Between themselves and the bars, the boards are attached with self-tapping screws. In order to avoid skewing the door, the third beam is nailed diagonally.

Directly the house itself, built from decorative building materials, should be left open. Sometimes it is sheathed with slate, metal tiles, bricked or decorated in another way. Be sure to treat all the wood with an antiseptic to increase its service life by a couple of years, and then cover with varnish or paint. A concrete ring is often lined with a decorative stone. Unusually and beautifully, the well looks decorated with a stand for buckets or benches.

Now it will not be difficult for you to build a house for a well. We considered one of the easiest ways. Having understood a simple design, you can move on to more complex and intricate structures. You can draw ideas and inspiration from photos and pictures on the Internet, and read about it on our website.