Dry-running relay for the pump: wiring diagram, principle of operation, adjustment

If the pressure in the pump drops, the device needs protection. For this purpose, special relays are used. The standard model consists of a pin, a set of contacts and a special closing cable. There is an adjustment screw at the top of the device. There is a small spring on the pin. The contactor in the device is installed with a starting mechanism. Housings are most often made of aluminum alloy. In the lower part of the modifications, nozzles of different diameters are installed.

How the modification works

How does a dry-running relay for a pump work? When the pressure inside the system drops, the contactor is activated. A voltage passes through the contacts, which is applied to the winding. The screw acts as a retainer. The spring is compressed by a pin. When the pressure drops, the contacts open. A contactor is used to switch off the voltage.

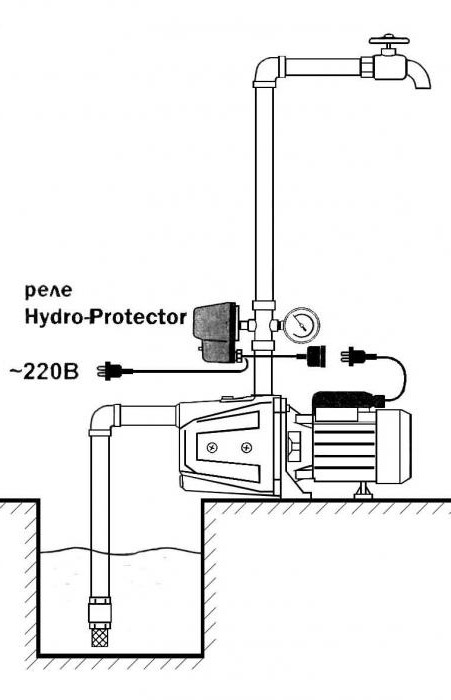

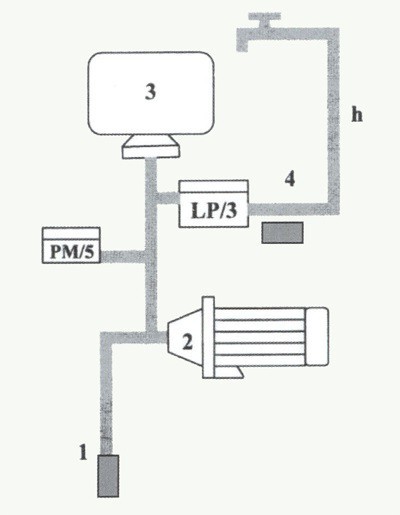

Dry-running relay for pump: wiring diagram

It is necessary to connect the device via an adapter. In this case, the outlet is connected to the tube. The cable is closed at the terminal. The cover is directly fixed to the pump body. A nut is needed to tighten the outlet. The nipple is often held in place with a clamp. Some types of relays are connected through a feedthrough adapter for two outputs. If we consider a circuit with several pumps, then a contactor expander is used.

Relay adjustment

In order to adjust the device, a screw is used, which is located in the upper part of the case. To adjust the model, readings are taken from the sensor. To raise the allowable pressure level, the screw is turned clockwise. At undervoltage, the speed of contact closure slows down. Also, the problem may lie in the contactor with the starting system. To lower the pressure level, the screw is turned counterclockwise. Much in this case depends on the parameters of the relay and the maximum power of the pumps.

Device types

There are flow and float devices. Models can be made with one or more cameras. Low pressure versions are suitable for low power pumps. Streaming devices are available in a variety of sizes. For powerful pumps, there is a high pressure switch.

Streaming devices

In hydraulic power plants, dry-running flow switches for the pump are often found. The operating principle of the modifications is based on changing the limiting pressure. This process takes place by changing the position of the plate. It is located at the bottom of the case. It should also be noted that the relays of this type are equipped with wired contactors. There is only one start button. Many models use power contacts. The circuit is closed by pressing the plates. The dry-running relay for the pump is connected via an adapter.

Float models

The most dimensioned are considered to be dry-running float switches for a pump. The device is adjusted by tightening the screw. The principle of operation of the modifications is based on pressure change. All models have one pin in the body. In this case, the branch pipe is located with a ring at the bottom of the structure. Most relays use a manual setting system. Devices of this type work from the network. The frame is usually made of plastic. The contact plates can be upright. Most relays operate at low frequency. The models are suitable for pumps from 4 kW. The operating frequency is 55 Hz on average. There is a nut in the upper part of the modification. In this case, the clamping screw is located on the pin.

Devices with level sensor

A dry running relay for a pump with is considered to be quite common. However, it is important to note that the models have a number of disadvantages. First of all, experts say that the models are difficult to customize. If he talks about relays on contactors, then they use one input. This way, failures often occur. It is also important to note that the models are not capable of working with submersible pumps. The devices are connected via a cable. The relay chamber is made with a solid base.

Low pressure models

Dry-running switches for low pressure pumps are produced with only one chamber. Contactors for modifications may differ in design. Most of the devices operate on a 220 V network. At the same time, their operating frequency is at least 45 Hz. It should be noted right away that the models are suitable for pumps with a capacity of no more than 3 kW. The contacts on the plate are in a horizontal position. In this case, the pins are installed next to the plate. In total, the modifications have two nuts. A clamping screw is used to adjust the pressure. Small diameter pins are often used. Models of this type are well suited to work with submersible pumps. Frameworks in devices are used with varying degrees of security, and in this case, much depends on the manufacturer.

High pressure devices

Dry running relays for high pressure pumps are in great demand. First of all, the models are used at hydroelectric power stations. They are well suited for pumps used in plumbing systems. Their contactors are used for two outputs. The working nuts are located at the top of the housing. It should also be noted that there are modifications for two cameras. Their outlet pipe is located in the center of the base. Most of the models are foldable on the basis of a dipole contactor. Mods use multiple pins. The devices are well suited for submersible pumps. The branch pipes are available with a diameter of 2.3 cm. The relays operate at least at a frequency of 40 Hz. The output cable must be connected to. A clamping screw is provided to adjust the plate. To equalize the pressure inside the system, the nut is turned clockwise. Sensors are very rarely found in modifications of this type. The start buttons are located directly on the contactors. The models are very easy to maintain.

Single chamber models

Single chamber dry-running relays for the pump are manufactured with one or more pins. Most modifications operate at low pressure. If we consider a simple relay, then it uses a wired contactor from a 220 V network. The minimum operating frequency is at 45 Hz. The first nut is located on the pin. To increase the pressure in the system, the screw is turned clockwise. If we consider the dry-running relay for the Grundfos pump (with a double contactor), then it uses two cable outputs. The minimum frequency for the modification of this type is 55 Hz.

Dual chamber devices

Double chamber devices are manufactured with low conductivity contactors. Most models are equipped with multiple pins. The nuts are usually found on the top of the body. The outlet is used with a diameter of 4.4 cm. The devices are suitable for high power pumps. Modifications work from a 220 V network. If we consider models with drive contacts, then they use a starting mechanism from the module. The minimum operating frequency is 30 Hz. The frame is often made of steel. The pressure is increased by adjusting the screw. The clamping plate in the devices is located under the contactor. The relay has a base with a seal. Most devices are equipped with a pin lubrication cap.

Three-chamber models

Three-chamber devices allow very precise regulation of the pressure inside the system. Most of the modifications are started from the module. To connect the device, adapters with a ring are used. The models are suitable for pumps from 4 kW. Their operating frequency is at least 4 Hz. Some relays are made on drives. Covers are usually installed over the pin. Some devices are manufactured with two clamping plates. The output cable leaves the contactor. The relay of this type operates as standard from a 220 V network.

Devices for 2 kW pumps

Relays for pumps are usually made with one pin. Most modifications are equipped with overlays. If we consider devices with wired contactors, then they have two outputs. It is also worth noting that there are models with support legs. The cases are most often made of stainless steel. The cable at the relay leaves the contactor. The devices operate from a 220 V network. Connection to the pumps occurs through a branch pipe.