Marina pumping station and its advantages

A pumping station is a set of equipment through which the organization of autonomous water supply to a house or a summer residence from sources such as a well and a well is carried out. The stations belong to the category of surface pumps - water is taken through a hose immersed in the source, while the unit itself is located on the surface.

This article will consider the pumping stations Speroni Marina, which is home to Italy. We will study the advantages and disadvantages of such equipment, their technical characteristics and get acquainted with the model range of equipment. Recommendations for the repair of pumping units will also be presented and their most frequent malfunctions will be given.

1 Device and connection of the pumping station

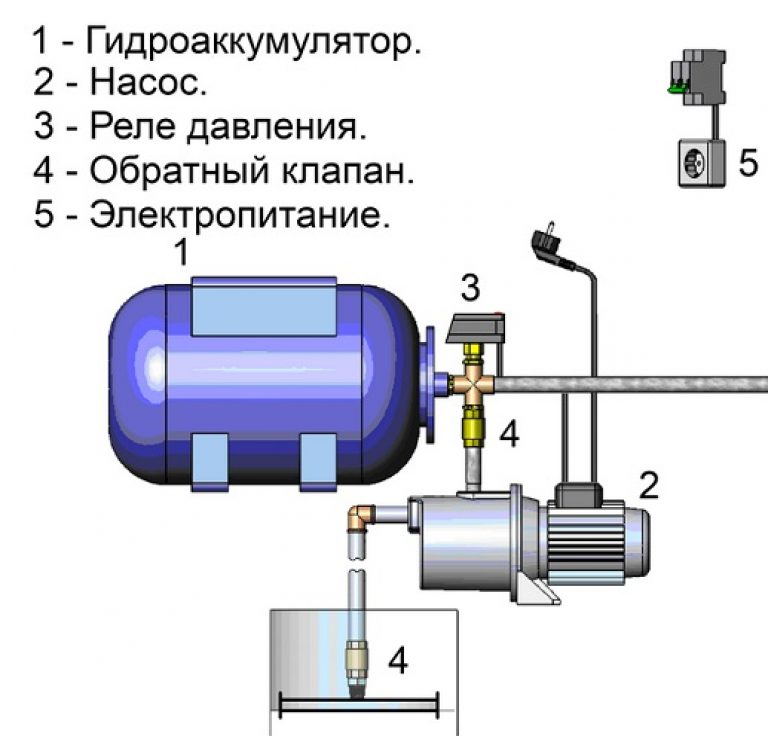

The design of Marina pumping stations, which are manufactured by Speroni, is quite simple - in terms of layout, they practically do not differ from analogues in their price category. Unit device consists of the following nodes:

- centrifugal water pump;

- hydroaccumulator;

- pressure switch;

- pressure gauge;

- temperature sensor.

The device of Marina stations does not imply the presence of a check valve, therefore, to increase the safety of the system, the user needs to mount it himself. The valve must be installed on the outlet of the pump, it will prevent the pumped water from moving in the opposite direction in the event of an unexpected shutdown of the equipment.

Also, it will not be superfluous to install a coarse filter at the inlet of the suction pipe, if there is one, the amount of mechanical particles entering the pump decreases, which has a positive effect on its service life.

The connection of such units does not require special equipment and can be done by hand. Initially, it is necessary to mount the pump to the water supply source, it must be located on a solid platform, which will exclude vibrations during operation.

A water intake hose is connected to the pump, which is lowered into a well or well. Further, a plastic supply pipe is diverted from the station's accumulator, which is connected to the water consumption points inside the house.

Upon completion of the connection, the operability of the system is checked - at start-up, the pump must be filled with water (a special hole is provided for this at its neck). During operation, the pump pumps water into the accumulator (storage tank), when it is filled, the pressure switch is triggered and the mechanism is turned off.

After the water in the accumulator has been used, the relay detects the decreased pressure and turns on the pump - this way an automatic adjustment is performed, thanks to which the Marina station provides the house with water without your intervention.

1.1 Advantages and Disadvantages

The popularity of Marina pumping stations is due to the fact that this equipment has a number of operational advantages over competitors. The main trump card is high-quality assembly, since the pumps are made directly in Italy, and not in China. These are reliable and durable units, the minimum service life of which before scheduled repair is 3-4 years.

Among the strengths also highlight:

- low power consumption;

- body and internal parts made of corrosion-resistant materials;

- low noise and vibration level during operation;

- the presence of overload protection systems even in the cheapest models;

- possibility of long-term operation in any power modes.

However, when choosing such a station for private use, it should be borne in mind that the equipment is designed to pump clean water, and it will not work to use it as a drainage pump.

1.2 Pumping station Marina - device, cleaning, starting (video)

2 Model range of equipment

The product line of the Speroni company (Italy) includes 4 series of Marina pumping stations:

- Marina CAM - a budget option for water intake from wells up to 9 m deep;

- Marina APM - pumps for wells up to 50 m deep;

- Marina Idromat - units equipped with a regulator that turns off the pump during dry running.

Let's consider each of the presented lines in more detail.

2.1 Marina CAM

The CAM series consists of equipment made in a cast iron or stainless steel case, with internal fittings made of food-grade polymers. Several models are presented, the power of which varies in the range of 0.8-1.7 kW, and the head is 43-60 m.

The volume of the accumulator can be 22, 25 or 60 liters. These are the most affordable stations for private use, the cost of which starts from 7 thousand rubles.

Among the stations with an optimal price / quality ratio, we will single out:

- Marina Cam 80/22;

- Marina Cam 60/25;

- Marina Cam 100/25.

The Marina Cam 40/22 pumping station is equipped with a 25-liter hydroaccumulator, the capacity of which will be enough for a family of 3 people. The throughput of the unit is 3.5 m 3 / hour, the maximum lifting depth is 8 m. The price is 9 thousand rubles.

Marina Cam 100/25 has similar technical characteristics - a tank of 25 liters, a throughput of 4.2 m3 / h, however, this model is equipped with a pressure boosting system, which significantly increases the delivery head - up to 45 m, compared to 30 m for CAM 40 / 22.

2.2 Marina APM

Wells pumps of the ARM series have a maximum water intake depth of 25 m (model 100/25) and 50 m (200/25). This is more power and overall equipment, the weight of which can reach 35 kilograms. As an example, consider the popular Marina ARM 100/25 station.

Specifications:

- head - up to 20 m;

- throughput - 2.4 cubic meters / hour;

- centrifugal motor power - 1100 W;

- diameter of the supply pipe - 1 ".

AWP 100/25 is made in a stainless steel case, the model is equipped with overheating protection and a water level control system in the hydraulic tank. ARM100 / 25 is intended for pumping clean water, without mechanical impurities, the temperature of which does not exceed 35 degrees.

2.3 Typical faults and repairs

Marina pumping stations have established themselves as reliable and durable equipment, however, like any other equipment, they are not insured against breakdowns. We bring to your attention a list of the most common breakdowns and ways to eliminate them:

- Lack of water supply when the pump is on, which may be caused by a loss of tightness in the conductive pipelines and a worn check valve. Check initially to see if you forgot to fill the pump housing with water. If there is, inspect the check valve and its tightness against the pump nozzle, and also check the condition of the water intake pipe - all damaged components must be replaced. Similar problems are possible if the impeller is damaged, to replace which it will be necessary to disassemble the unit.

- Water is supplied in jerks due to a damaged accumulator. The main malfunction of the hydraulic tank is a damaged membrane. To determine if it is intact, press the nipple (located on the tank body), if water flows from the nipple, and not air, then the membrane is torn. It is quite easy to install the membrane, you just need to unscrew the fixing ring from the neck of the tank, pull out the old part and mount a new one in its place.

- Reduced water supply pressure. The reason for this can be both a faulty hydraulic tank and problems with the pump. In the first case, the depressurization of the tank is most likely to blame - inspect the case for cracks, repair the detected deformations and pump air up to the standard value. If the tank is intact, the problem must be looked for in the deformed impeller of the centrifugal impeller inside the pump.

We will separately consider the situation when the pumping station does not want to work in automatic mode - the unit does not turn off when the tank is full and does not turn off when it is empty. The wrong adjustment of the pressure switch is to blame here - it is usually calibrated at the factory, but there are exceptions.

The above diagram shows a standard pressure switch for Marina pumps. On it, under the plastic case cover, there are two springs. Most of them rotate clockwise, it is responsible for the minimum pressure in the tank at which the station turns on. By rotating a small spring, we set the maximum pressure, upon reaching which the pump is turned off.

The pressure switch must be adjusted with the equipment disconnected from the mains. Before starting the calibration, the water must be drained from the tank, the level of air pressure is also important - it must correspond to the value recommended by the manufacturer.