Why do you need a frequency converter for a pump? Used water supply converters

The basic element that ensures the functionality of the pump is the electric motor. Previously, the adjustment of the working process took place due to automation, now this problem is solved by a frequency converter for pumps.

Functional purpose of the frequency converter in the pump design

An inverter (frequency converter) provides regulation of the pump operation much better than a relay. It works at the same time as a stabilizer, an automation and a workflow regulator. Thanks to it, the high efficiency of the device is ensured:

- The level of electricity supply, if necessary, and the engine speed are reduced, which helps to protect the pump from premature wear.

- The formation of excessive pressure in the pipes is prevented.

- The problem with voltage surges is solved, which also definitely increases the life of the pump.

Mostly already in the process of assembling the pumping station, it is implanted. Such devices include the models of the very famous Grundfos pump.

Visually, it is a box equipped with electronics (several boards, a sensor that measures, and an inverter that equalizes the voltage level) and a small-sized screen.

More expensive samples are equipped with microprocessors. Batteries, additional equalizers, and so on may be built-in.

The used converters can be of single-phase or three-phase type.

According to the principle of operation, the frequency converter is quite simple. A wave of electric current is applied to the circuit boards of the device. The inverters and stabilizers located there ensure its alignment. At the same time, the sensor reads pressure data and other relevant information.

All information is redirected to the automation unit. Further, the frequency converter evaluates them, determining the power level that needs to be supplied, and, in accordance with this, supplying the amount of electricity necessary to continue working.

As a result, the adjustable frequency drive can adjust the smoothness of starting of electric motors, the level of water pressure and stopping the operation in an emergency. The list of all "duties" assigned to the frequency operator is constantly expanding due to the improvements made by the developers.

The process of controlling the actions of the converter is carried out just by pressing the desired button with orientation to the data displayed on the screen. More expensive devices are capable of recognizing more commands. The highest quality models are designed for several dozen operating modes with a change in speed and program.

The installation and purchase costs of the converter are fully reimbursed within one year of operation

The list of positive functions of the frequency converter:

- The ability to equalize the input voltage.

- Providing pump power regulation.

- Creation of conditions allowing to save energy.

- Increasing the service life of pumping equipment.

- Providing the ability to work without a hydraulic accumulator.

- Stabilization of intrasystem pressure.

- Reducing the noise level of the pump.

He also works as a deputy of automation.

Negative points:

- High cost of the device.

- Configuration and connection are usually only available to technicians.

The frequency converter works in the design of the pump as follows: with a significant drop in the pressure level in the hydraulic tank (determined using a relay), the frequency converter receives a corresponding signal and gives a command to start the electric motor. In this case, everything is carried out "without sudden movements", the power increases gradually, providing insurance against hydraulic overload. Currently, the models of converters provide regulation of the acceleration time from 5 to 30 seconds.

While the acceleration is being carried out, the converter constantly receives information about the pressure level in the pipeline. As soon as this level reaches the desired value, the acceleration stops, the engine continues to operate at the reached frequency.

How to select and install equipment?

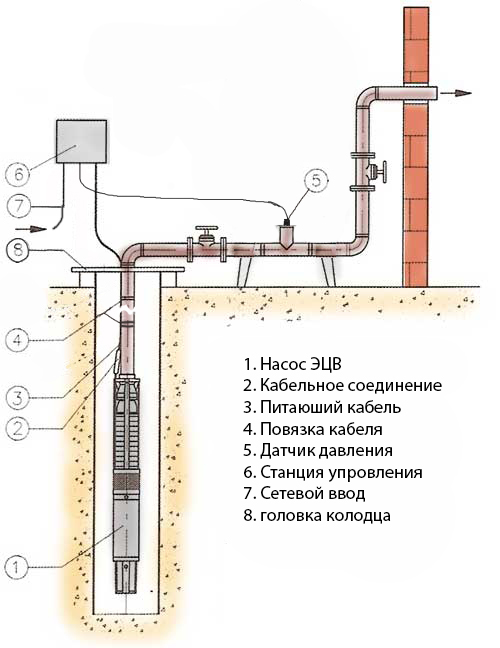

The standard equipment of the pumping station consists of:

- Submersible or surface pump;

- Pressure gauge;

- A hose equipped with a stainless steel coating;

- Hydraulic accumulator;

- Water pressure switch.

Additional equipment includes:

- Uninterruptible power supplies;

- Sensor;

- Blocks;

- Control relays etc.

If the design of the existing pumping equipment is not equipped with a frequency converter, then you can install it yourself. Typically, the documentation supplied with the pump model contains instructions as to which converter the pump of this type can communicate with.

In the absence of such information, it is necessary, relying on significant parameters, to select the converter yourself:

- Power level.

Correspondence is required between the capacity of the drive and the inverter.

- Input voltage value.

An indication of the current at which the inverter operates. Here it is necessary to take into account what the potential fluctuations in the network may be (a low voltage level provokes a stop, a high voltage level - a breakdown).

- Pump motor category.

Single-phase, two-phase or three-phase.

- Frequency control range limits.

For a borehole pump, 200 - 600 Hz is required (depending on what is the primary pump power), for a circular pump - 200 - 350 Hz.

- Matching the number of control I / O to the operational needs.

The more there are, the more possibilities for managing the workflow.

- Choosing a suitable control method.

In the case of a borehole pump, there is a remote control that allows control directly from home, and the circulation pump works perfectly with a remote control.

It is necessary to determine the reliability of the purchased devices indirectly by the duration of the warranty period. Accordingly, the larger it is, the better the quality.

Where to install the pump converter?

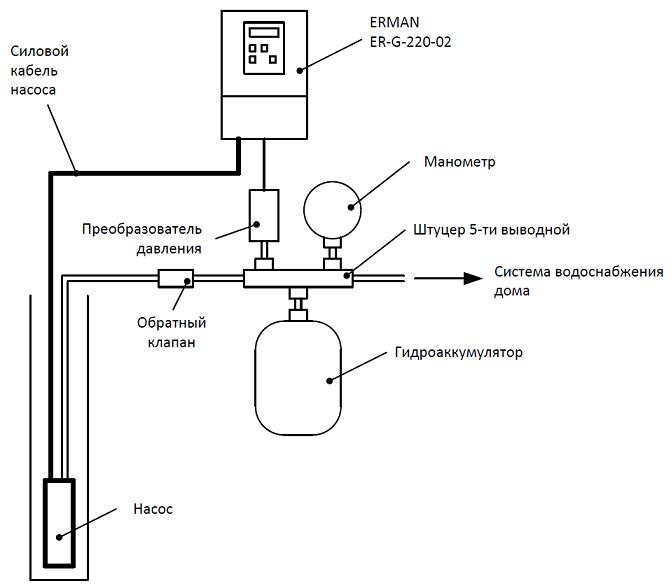

Frequency converters with hydraulic connection are installed directly on the pressure line. Without such a connection, only a water pressure sensor connected to the inverter is attached to the line.

The transform is located as close to the pump as possible, but only inside the heated room. The general power connection diagram is simple and straightforward.

Models of transducers for the pump

- Grundfos Cue

Converters manufactured by a Danish-based pump manufacturer. As a result, these frequency drives are designed in maximum accordance with the design of the pump models from Grundfos. The device is responsible for the fine regulation of the entire mechanism, the implementation of safety and control functions. Transducers of the Cue system are distinguished by a variety of high-quality models (more than 15 types in the range), but their cost is appropriate. In addition, the price directly depends on the mechanism of what power the frequency converter is required. Among the range of models, you can find converters for a single-phase pump (), and for a three-phase (Micro Drive FC101).

- Erman E-9

The converters of this company are distinguished by their budget. They are responsible for torque compensation, smooth start-up, pressure control and have up to 24 different control modes. Power matching is selected on an individual basis. There is a protective case that protects against dust and dirt.

- Hyundai N 50

The frequency converter is single-phase type. Can be used in household appliances. The power level is 0.7-2.5 kW. Small-sized, which makes it easy to install in any device. It is notable for the fact that it provides fine tuning thanks to several tuning modes and 16 discrete speeds. It costs about double the previous model.

- PowerFlex 40

Models of this brand are versatile and very popular. Their distinctive feature is high-quality drive and vector control. The drive, among other things, dampens noise during engine operation, automatically picks up the speed of the electric motor, protects the entire mechanism from overload and overheating, and ensures a smooth start. The cost is comparable to Grundfos Cue.

Using the pump in autonomous water supply and heating systems

Pump models in this category are considered very productive, but they have an extremely high level of energy consumption, which, of course, makes it difficult to operate. Of course, frequency converters can reduce the amount of energy consumption, the pressure level and extend the service life.

Most modern pumps are designed according to the throttling principle. The electric motors of these mechanisms are in operation at the upper power limit, that is, literally for wear. Often, due to the lack of smoothness when turned on, powerful hydraulic shocks are observed, which spoil the design of the pump. To fine-tune such a mechanism, you also need to try pretty hard.

The calculation of data for pumping equipment is always based on the maximum power level, although the mechanism experiences maximum load only occasionally with peak water consumption, which does not happen often. The rest of the time, working to the limit is completely unjustified. Just at such moments, a frequency converter for a circulation and borehole pump reduces energy consumption by 30 - 40%.

Among other things, the use of a frequency converter in the pump station providing water delivery prevents the problem of "dry running". It is relevant in cases where there is no water inside the system, and the engine continues to run. Due to "dry running", the engine may overheat and breakdown of the mechanism as a whole. This proves once again the necessity of using a converter.

Single-phase frequency inverter for a pump in a domestic water supply system

Ergonomics of devices is a very significant indicator in the framework of consumer services. Improving this parameter for a water supply system using a low-power single-phase pump model is difficult, since this requires a converter with an input / output voltage level of 1x220V, and it is not easy to find one.

Usually, household pumps have no complaints about energy consumption, but this does not compensate for the purchase costs, due to its rare operation.

However, the installation of the converter does not lose its relevance, since it helps to maintain a constant network pressure. In other words, a request for comfortable operation is carried out here.

This option is especially important when using hot water. That is, the use of a frequency converter eliminates temperature jumps and changes in the pressure force.

Single-phase converters are suitable for both submersible and surface pumps.

Single Phase Frequency Converter for Home Use

Inverters of the standard type are usually not equipped with a hydraulic connection. An attempt to self-upgrade the device for such needs may turn out to be useless, even if a specialist gets down to business.

Recognizing this problem, manufacturers engaged in the production of frequency converters have created a special single-phase frequency converter for the pump that provides domestic water supply systems.

One such converter is the one equipped with a hydraulic connection and capable of performing all the standard tasks of a frequency converter.