Water pressure regulator for a pumping station: installations for comfortable network operation

Setting up the pressure regulator of a pumping station is one of the most critical manipulations carried out in preparing the equipment for initial start-up. This device is a sensor, at the command of which the pump must be started and stopped.

On any devices, including pressure switches, there are settings set by the manufacturer. But the owner of an autonomous network may have completely different needs, according to which it should function.

Therefore, the question immediately arises: "How to adjust the pressure of the pumping station?" We will try to answer it with the help of the video in this article.

Design features of the pressure switch

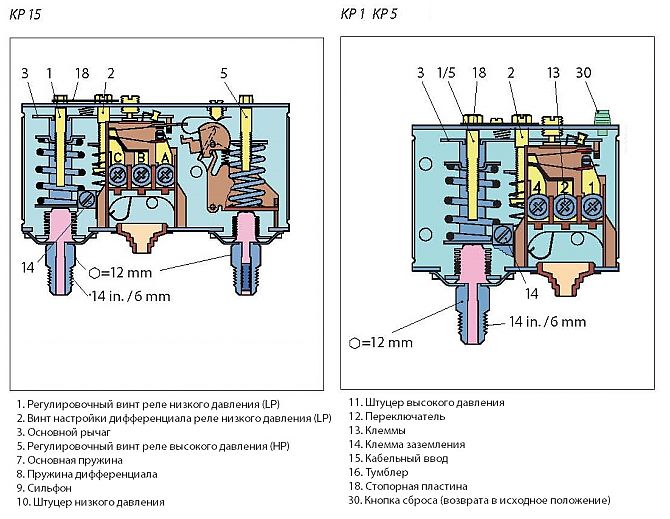

The device that automatically monitors the operation of the water supply network is a compact unit. It has two springs - for the lowest and highest pressure indicators.

The factory settings of the sensor are focused on the standard indicators of urban water supply networks: if the pressure reaches 2.5 bar, at its command, the pump is turned off, if it drops to 1.5 bar, it is started.

So:

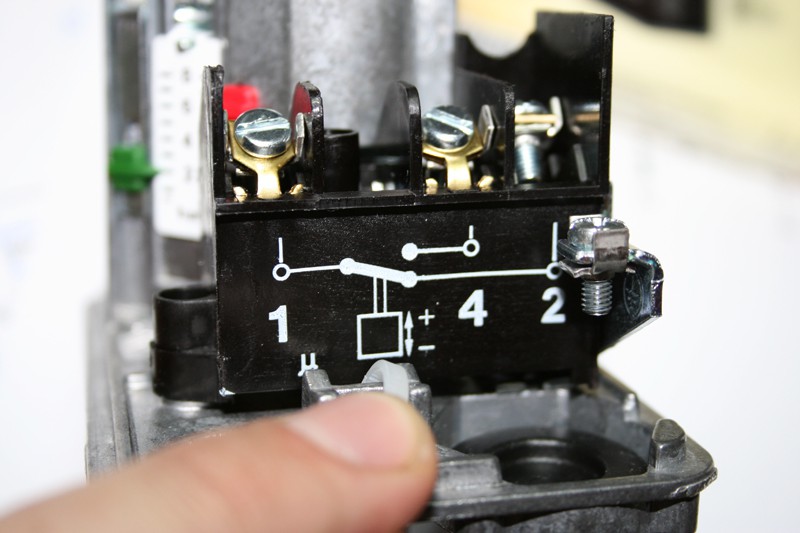

- The tension of the springs is adjusted with screws. They are interconnected by a membrane that acts on the piston under water pressure. And he, in turn, activates the contact group. In the photo below, you can see the regulator for which the springs are not closed, as in household models, with a plastic cover.

- When the pressure reaches the maximum mark, the spring is compressed, opening the relay contacts, and, accordingly, turns off the pump. At minimum pressure, everything happens exactly the opposite: the spring weakens, the contacts close. In fact, the water pressure regulator for the pump controls the operation of the entire network.

- Depending on the modifications of the devices and the power of the network, for implementation in which they are intended, the sensors can differ significantly in size, configuration, set and location of working parts. In accordance with the operational capabilities, their price also differs.

In general, the presence of a pressure sensor in the network ensures the stable operation of the system: uniform water consumption, constant pressure, energy savings, and an increase in the period of trouble-free operation.

Installing and configuring the sensor

In this case, the consumer only has to independently adjust the pressure in the pumping station by appropriately setting the relay.

Sealing the connection

When installing the sensor, it is very important to ensure that the threaded connection is tight. For this, all methods are good: special paste, flax, fum tape or Tangit Uni-Lok thread. The latter option is more reliable and allows you to achieve the desired result on the first try, provided, of course, that the thread is wound correctly.

So:

- To do this, the thread must be turned towards you, and the winding must be made from its base, gradually approaching the end. The first round of sealing material must be secured well by making a double turn. After installing the relay, the beginning of the winding will be located under the static nut.

- Subsequent turns are wound neatly and evenly so that the thread does not fall into the grooves of the thread. The amount of sealing material must be sufficient to prevent water leaks. But if you overdo it and wind too much, then in the end either the nut will not screw, or the winding will doubt that it will also lead to a leak.

When, in the process of screwing the relay onto the thread, the sealing material does not crumple, it means that it has been wound correctly. If the thread comes out, loops and gets tangled, the sensor will have to be removed and the thread rewound.

There are other options for sealing threads, one of which you see in the picture above.

Network connection

Before proceeding with the settings (see), the relay must be correctly connected to the network. According to the scheme proposed by the manufacturer of the device, on its body you need to find a group of contacts to which the wire will be connected. Its cross-section must correspond to the characteristics of the pump.

- After connecting the cable cores to the contacts, grounding is performed. For this, the ground wire is closed on the relay housing with a corresponding screw. After that, the relay is electrically connected to the pump. To do this, you need a piece of wire, which, observing the color of the cores, is screwed with one end to the remaining free contacts of the relay, and the other end to the corresponding contacts of the pump.

- Then you need to check the operation of the network: the pump should be started and monitored by the pressure gauge. The pressure should rise as water enters the system. After it reaches, for example, the 3 bar mark and the pump turns off, you need to open the taps. Now, as water is consumed in the pipeline or membrane tank, the pressure will decrease.

If the arrow of the pressure gauge shows the lower pressure limit, and the pump turns off, then the installation is correct. After you make sure that the factory settings of the relay, which are stated in the operating manual of the device, work as needed, additional adjustment of the pressure sensor of the pumping station can be made.

Re-configuring the relay

So, if for one reason or another you are not satisfied with the settings made by the manufacturer, the pressure sensor can be adjusted. Most often, it is required to increase the maximum pressure limit. Many houses have powerful plumbing fixtures: showers, jacuzzis, which require a pressure of 4-5 bar to start, while standard relay settings correspond to a maximum of 3 bar.

- To do the adjustment yourself, you need to remove the cover of the device with a screwdriver, under which you will see the adjusting nuts. A suitable wrench is required to turn them. After turning off the power supply and removing the relay cover, you can proceed with the configuration.

Here's how to adjust the pressure in a pumping station

The smaller regulator is responsible for the upper pressure reading. If you are happy with the lower limit and only want to increase the upper limit, turn the small knob clockwise. Then the upper pressure limit will increase, while increasing the range between the boundary values.

- If it is required to move the entire range upwards, that is, to change the lower pressure limit, the nut should be unscrewed on the large regulator. After these manipulations, the cover of the device must be installed in place, the power must be connected and, again using the pressure gauge, check whether the settings are correct.

When setting a higher maximum pressure limit, familiarize yourself with the transmitter specifications. It is quite possible that he is not designed for such pressure, and therefore will not be able to achieve it. In this case, the relay simply will not turn off the pump. This will lead to a breakdown of the device, as well as significantly accelerate the wear of the working parts of the pump.

- When reconfiguring the relay upward, one should not forget that it is undesirable to set the upper pressure limit more than 80% of the maximum possible indicator for this device. For household pressure sensors, this limit usually does not exceed 5.5 bar.

You should not reduce the limits of the lower indicator either. Ideal when set 10% above the minimum possible.

Pressure indicators that are borderline are usually indicated by the manufacturer in the product passport. If you really need a lot of pressure in the network, you should purchase a relay with the appropriate capabilities - and you do not need to bother with adjustment.